Device and method for lateral pressure test model of layered unloading and non-uniform side shift support

A test model, non-uniform technology, applied in the field of indoor model test system, can solve the problems of few layers, large one-time unloading depth, and rare experimental devices for earth pressure on support structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

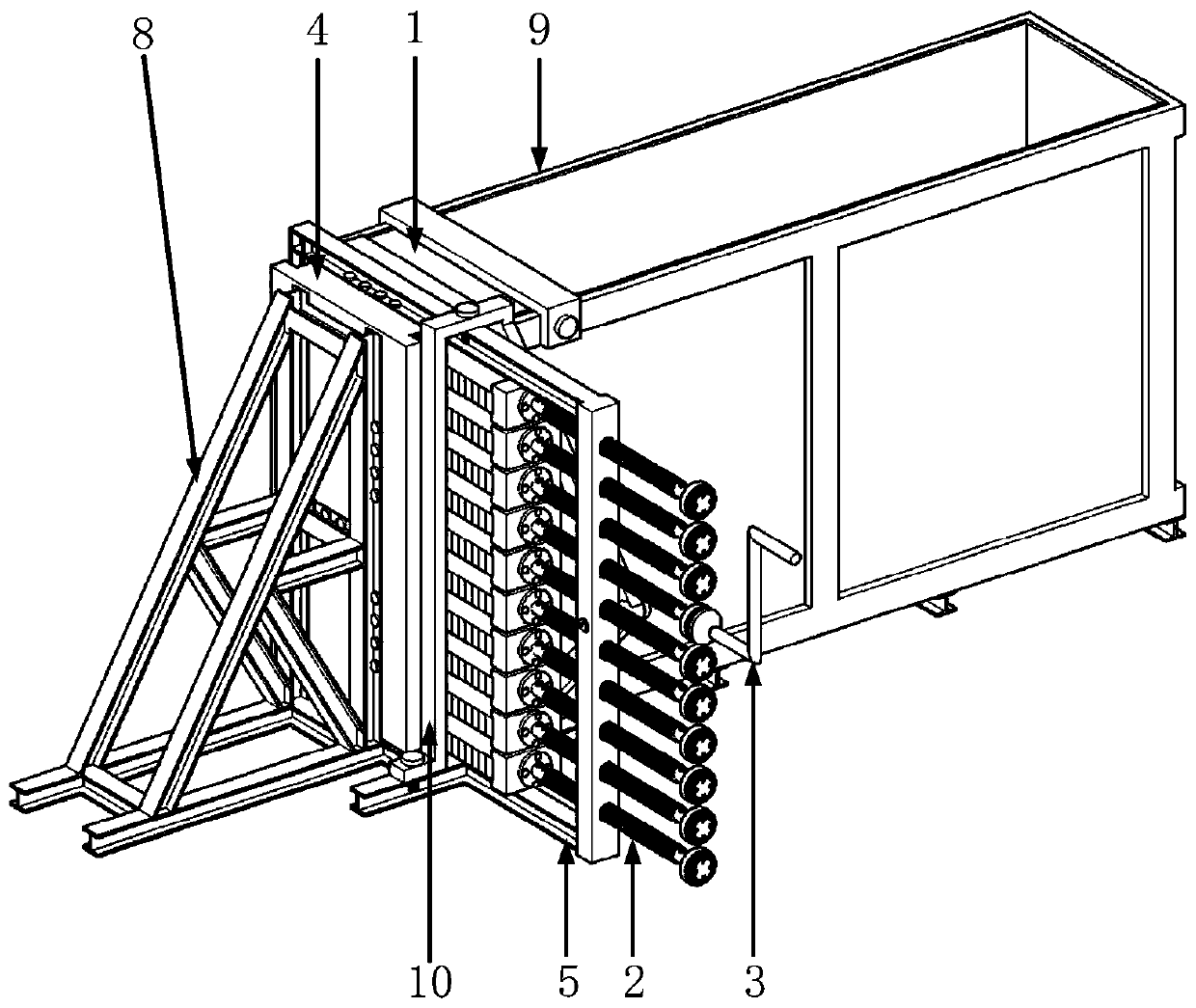

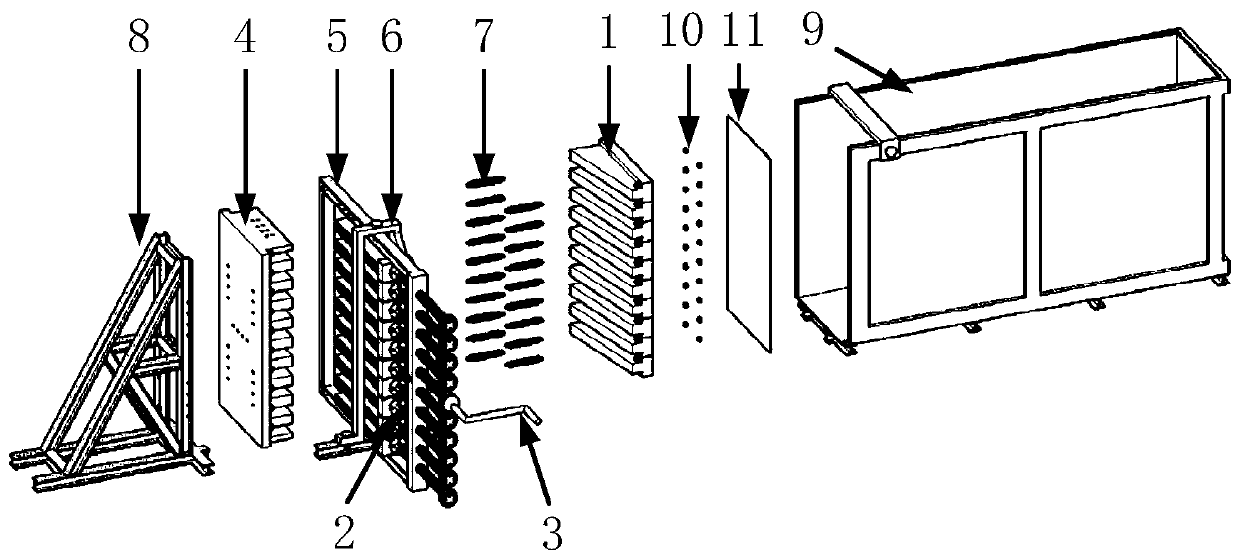

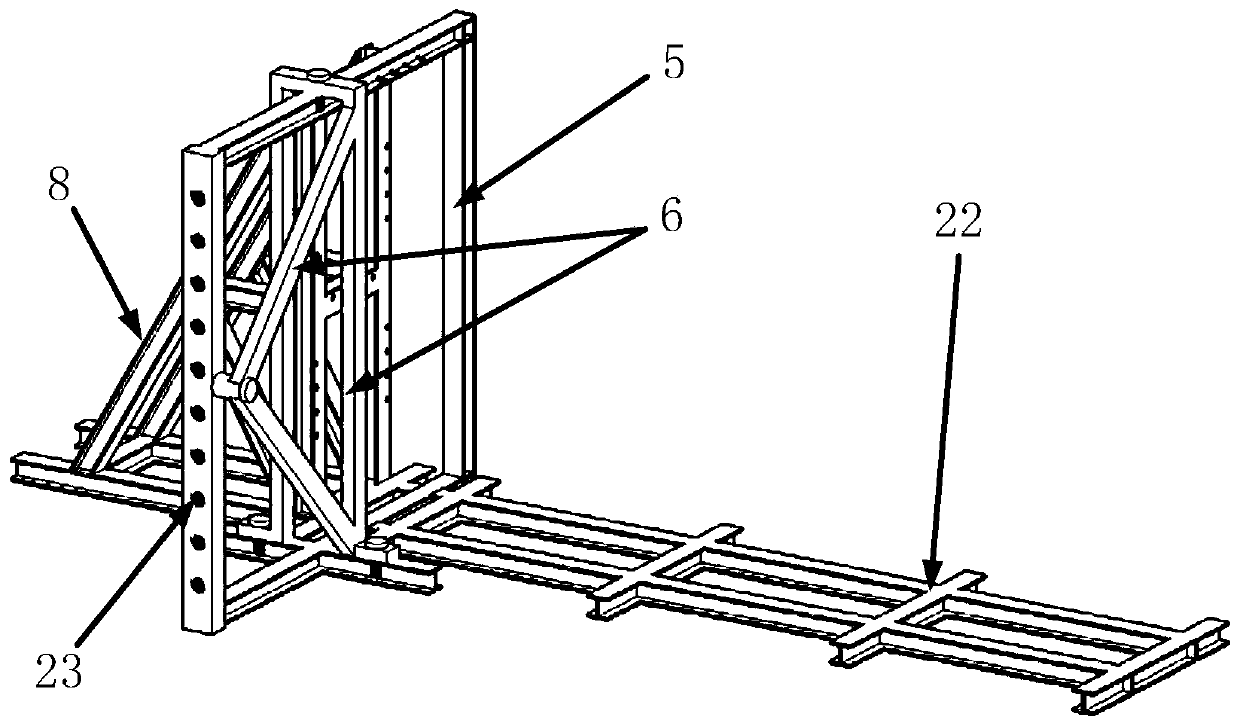

[0087] Such as Figure 1-Figure 9 As shown, a model device for lateral pressure testing of layered unloading and non-uniform side shift support, including: spliced retaining wall 1, loading unit 2, loading bend 3, rib ruler groove frame 4, loading frame 5, and loading frame reinforcement Part 6, return spring 7, triangular diagonal brace 8, model box 9, miniature earth pressure sensor 10, rubber film 11.

[0088] Such as figure 1 , figure 2 As shown, the model box 9 is a rectangular parallelepiped box with one end side wall missing, spliced retaining wall 1, bolt loading part 2, rib ruler groove frame 4, loading frame 5, loading wedge ruler 15, return spring 7, triangular diagonal brace The frame 8 and the miniature earth pressure sensor 10 are all arranged on the missing end of the side wall of the model box; the model box bracket 22 is located below the model box 9, and is connected with the model box 9 bottom plate by bolts.

[0089] As a preferred embodiment, the n...

Embodiment 2

[0139] Based on the device structure of the above-mentioned embodiment 1, a kind of indoor simulated foundation pit layered excavation soil pressure test model test method is provided, such as Figure 10-16 shown. Including the following steps:

[0140] (1) According to the actual setting of the layered number n of foundation pit excavation and the depth hi of each excavation, according to the method in Example 1, determine the size of the ribbed wall unit, the size of the loading wedge and other experiments The parts of the device are constructed and assembled in place;

[0141] (2) Zero adjustment, filling the model box with sand: Manually twist the loading handles of each loading unit directly, so that the scale of each loading wedge is at the zero position, and then evenly fill the model box with sand to a predetermined height.

[0142] (3) Manually turn the loading handle corresponding to the ribbed wall unit of the first layer outward until the limit displacement Sa1=S...

Embodiment 3

[0147] Based on the device structure of the above-mentioned embodiment 1, a kind of indoor simulation non-uniform displacement working condition soil pressure test model test method is provided, such as Figure 10-16 shown. Including the following steps:

[0148] (1) According to the accuracy requirements of the simulation and the cumbersome shape of the fabrication and operation of the ribbed wall unit, loading wedge, loading bolt and other components, the number of sections of the spliced retaining wall should be selected, at least not less than 10, and it is not suitable more than 20;

[0149] (2) According to the method calculation in embodiment 1, make, assemble each parts of experimental device;

[0150] (3) Manually twist the loading handles of each loading unit so that the scales of each loading wedge are at the zero position, and then evenly fill the model box with sand and soil to a predetermined height in layers;

[0151] (4) According to the predetermined non-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com