Device and method for testing lateral pressure of support of foundation pit during stratified excavation and non-uniform displacement

A layered excavation and testing device technology, which is applied in excavation, soil material testing, infrastructure engineering, etc., can solve the problem of large unloading depth at one time, rare experimental devices for soil pressure on the support structure, and a small number of layers and other problems, to achieve the effect of convenient reading, high precision and advanced reading principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

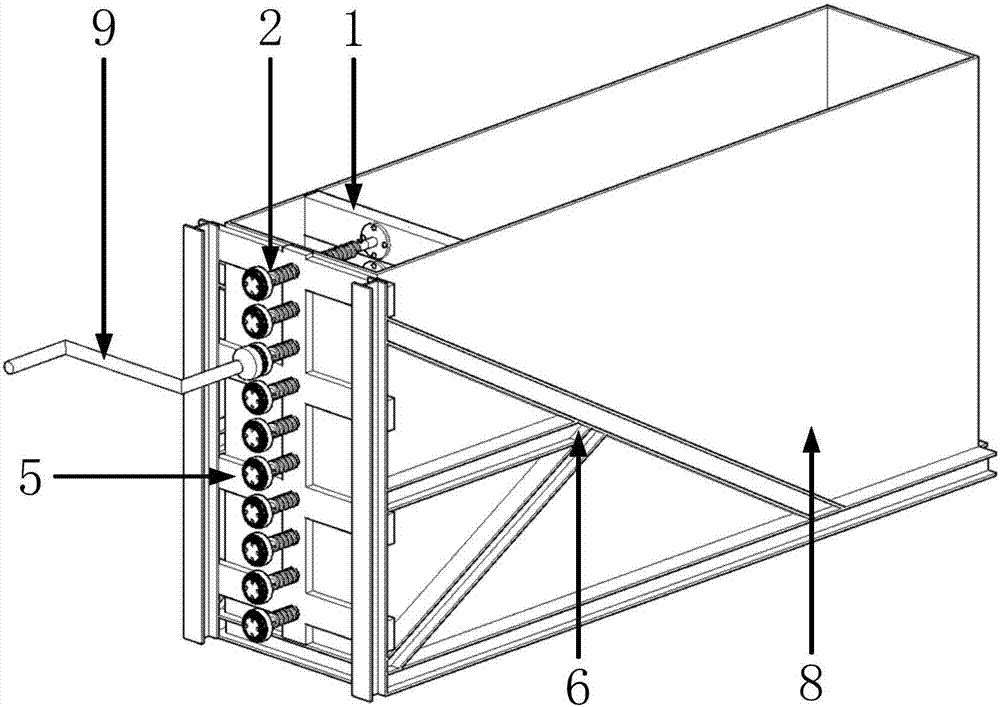

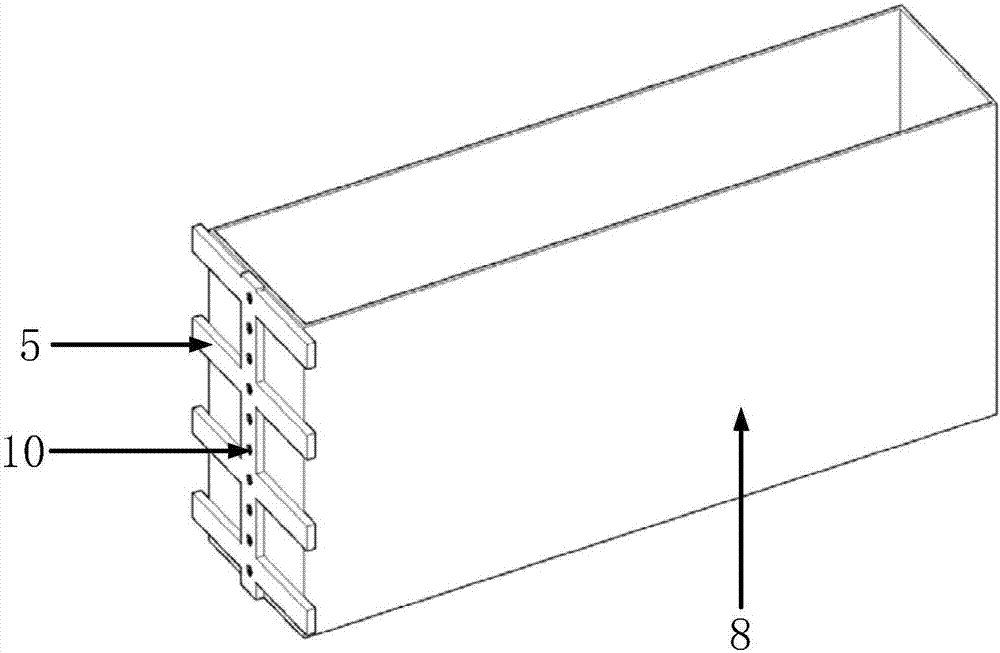

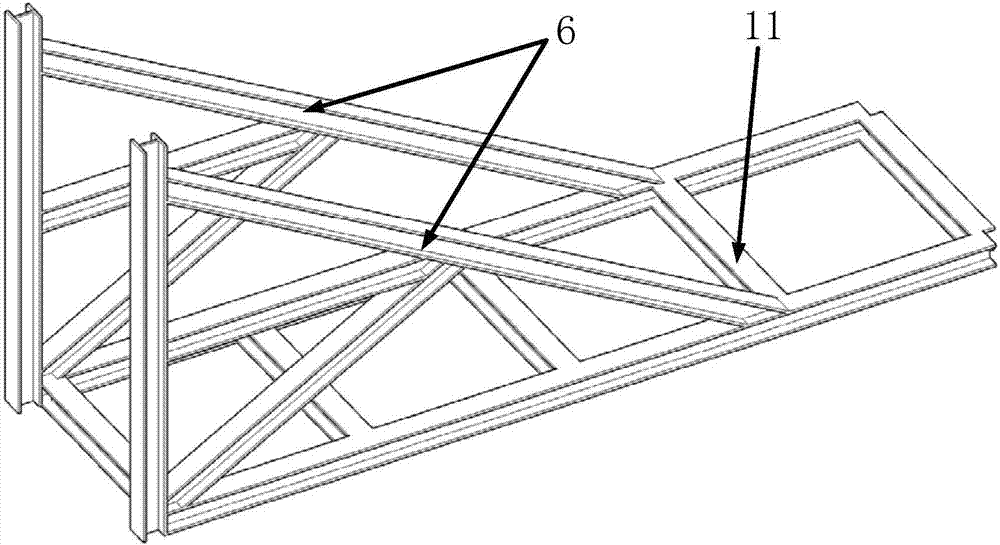

[0101] The total height of the splicing retaining wall 1 is H=1.5m, the width of the splicing retaining wall 1 is B=50cm; the number N of the wall pieces 7 forming the splicing retaining wall 1 is taken as N=10, and the average height of 10 wall pieces 7 is: length 50cm, height 15cm, thickness 8cm; the diameter of the bolt hole in the center of the wall piece 7 is 3cm, the net width of the wedge slope groove on one side is 2cm, and the slope ratio is 1:10.

[0102] In the loading bolt 2: the length of the loading bolt screw 14 is 15cm, the diameter is 3cm, the diameter of the loading bolt nut 13 is 6cm, and it is made of plastic.

[0103] The miniature earth pressure sensor 3 has a diameter of 1.2 cm and a thickness of 5 mm, and is arranged at three quarter points of each wall piece 7 .

[0104] The rubber film 4 has a thickness of 1 mm and a smooth surface.

[0105] The model box 8 is a cuboid with a net width of 50.1 cm, a wall thickness of 1.5 cm, made of plexiglass, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com