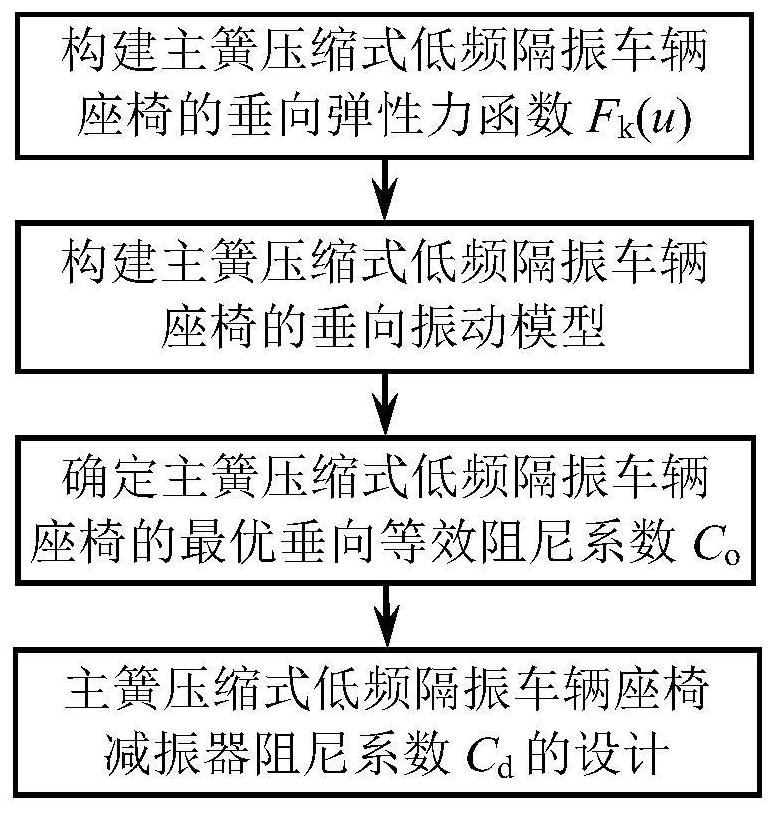

Design Method of Damping Coefficient of Main Spring Compression Type Low Frequency Vibration Isolation Vehicle Seat Shock Absorber

A vehicle seat and damping coefficient technology, applied in seat suspension, design optimization/simulation, instruments, etc., can solve the problems of high design cost and long cycle, and achieve high design cost, long cycle, and avoid repeated testing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] specific implementation plan

[0035] The present invention will be further described in detail through an embodiment below.

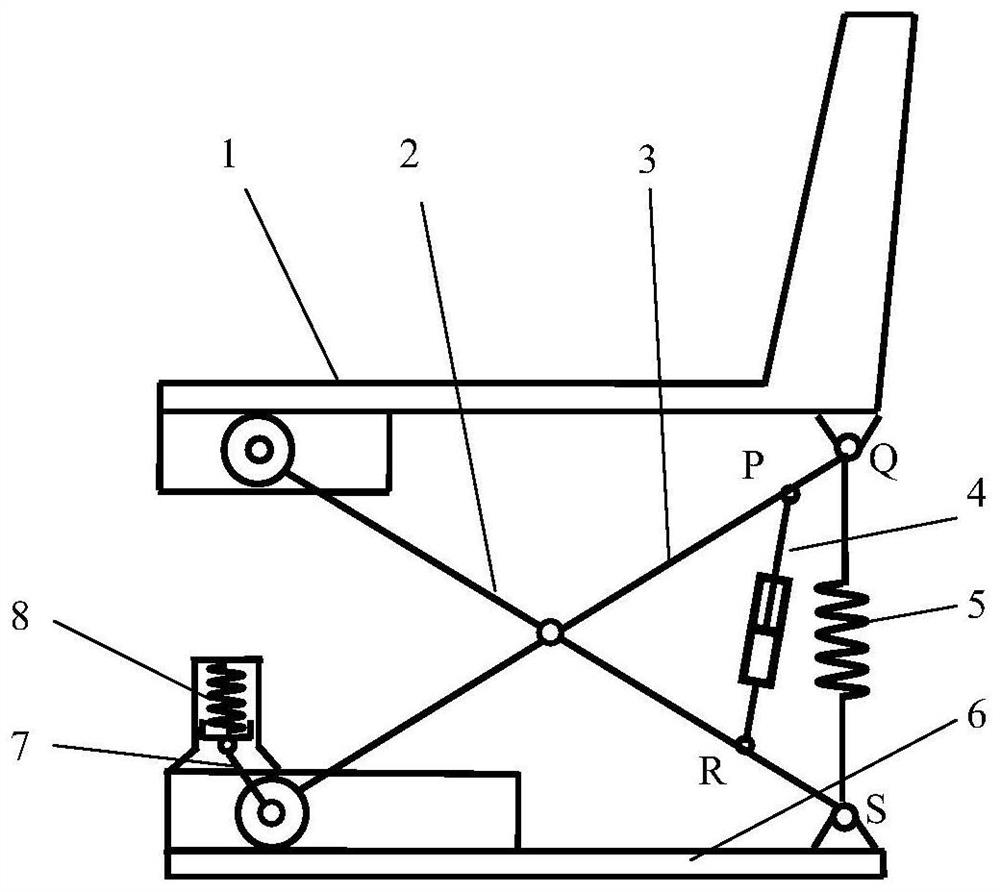

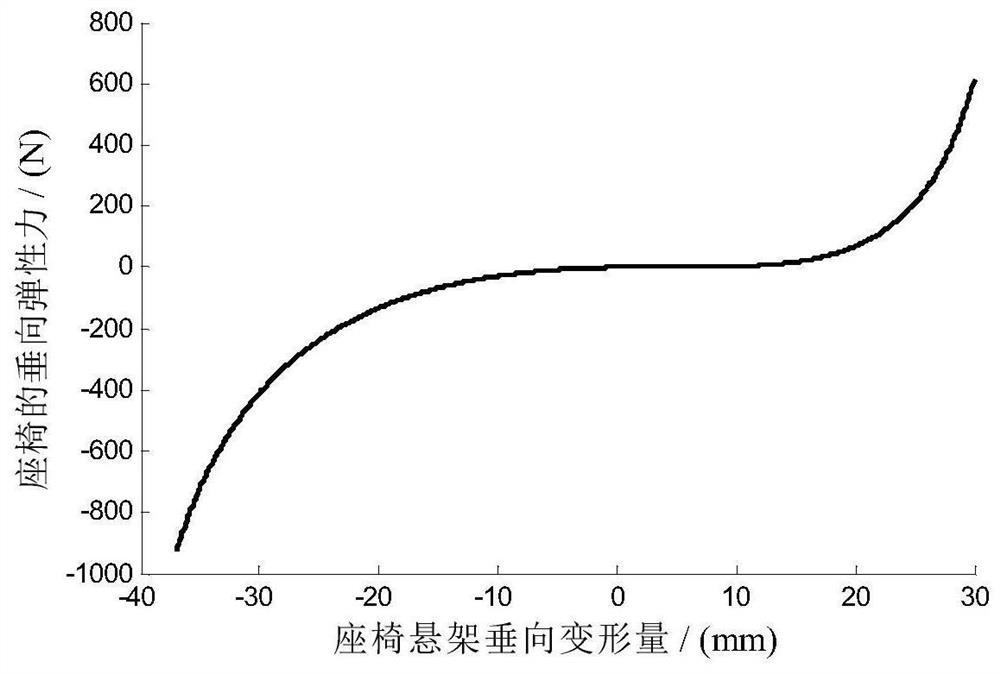

[0036] A vehicle is equipped with a main spring compression type low-frequency vibration isolation vehicle seat. The structural diagram of the seat is as follows figure 2 As shown, the initial angle θ between the first shear bar and the seat bottom is 49°, the initial angle β between the connecting rod and the seat bottom is 36°, the length of the first shear bar is L=600mm, and the length of the connecting rod is r=40mm , the distance from the lower installation point of the shock absorber to the hinge point of the first shear bar and the seat pan is a=60mm, the distance from the upper installation point of the shock absorber to the hinge point of the second shear bar and the seat panel is c=80mm, and the stiffness of the main spring K 1 =20N / mm, auxiliary spring stiffness K 2 =50N / mm, the rated mass of the occupant m=75kg under static bala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com