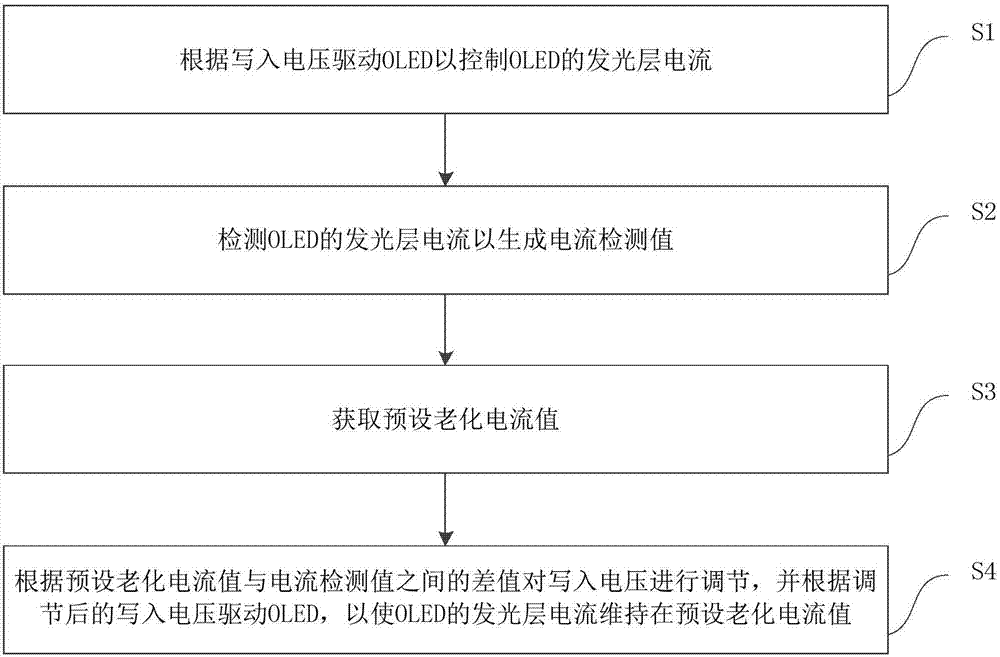

Organic light-emitting diode OLED life aging method and system

A light-emitting diode, an organic technology, applied to instruments, static indicators, etc., can solve the problems of poor uniformity of the backplane circuit, burnt power line, large current deviation of the light-emitting layer (maximum deviation, etc., to avoid L-Aging Insufficient or burn-like adverse effects, controlled aging amount, good aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

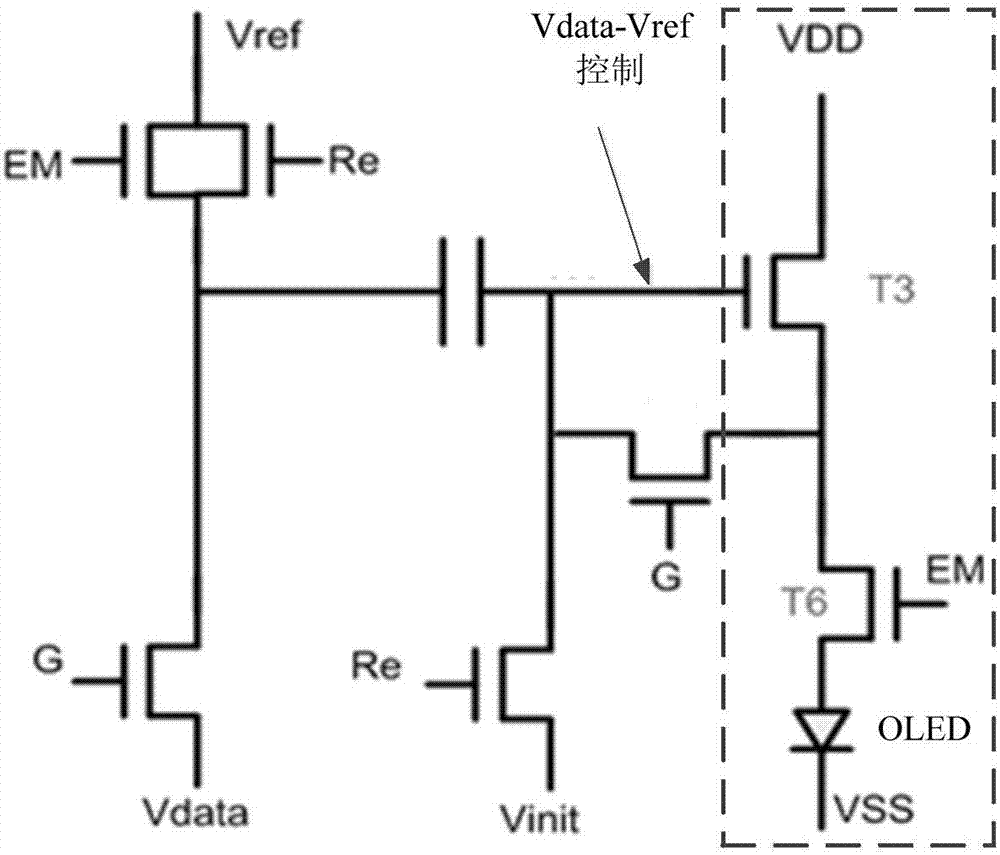

[0031] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

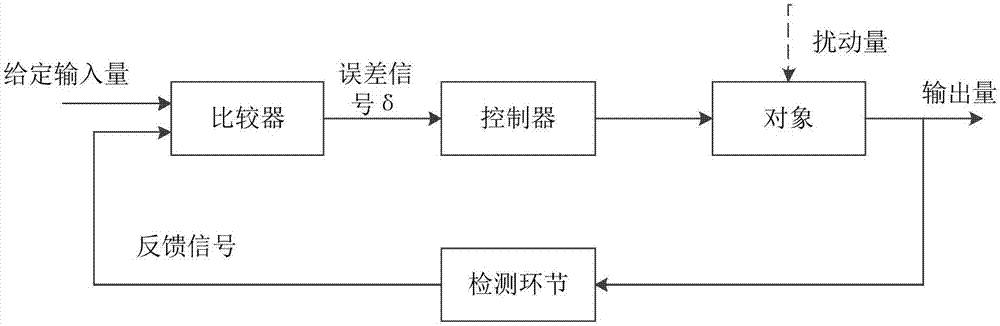

[0032] First, briefly introduce the principle of closed-loop control.

[0033] Closed-loop control is a basic control idea in cybernetics, and the control stability and control dynamic response performance of the closed-loop system are well guaranteed. Specifically, such as figure 2 As shown, the closed-loop control is corrected according to the output feedback of the control object, that is, the detection link can take the feedback signal from the output and feed it back to the input terminal to compare with the given input. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com