Efficient installation structure of switch socket panel and bottom case

A socket panel and installation structure technology, applied in the direction of coupling device, connecting device parts, electrical components, etc., can solve the problems of difficult installation, difficult installation, low work efficiency, etc., to solve the problem of low installation efficiency and improve The effect of working efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

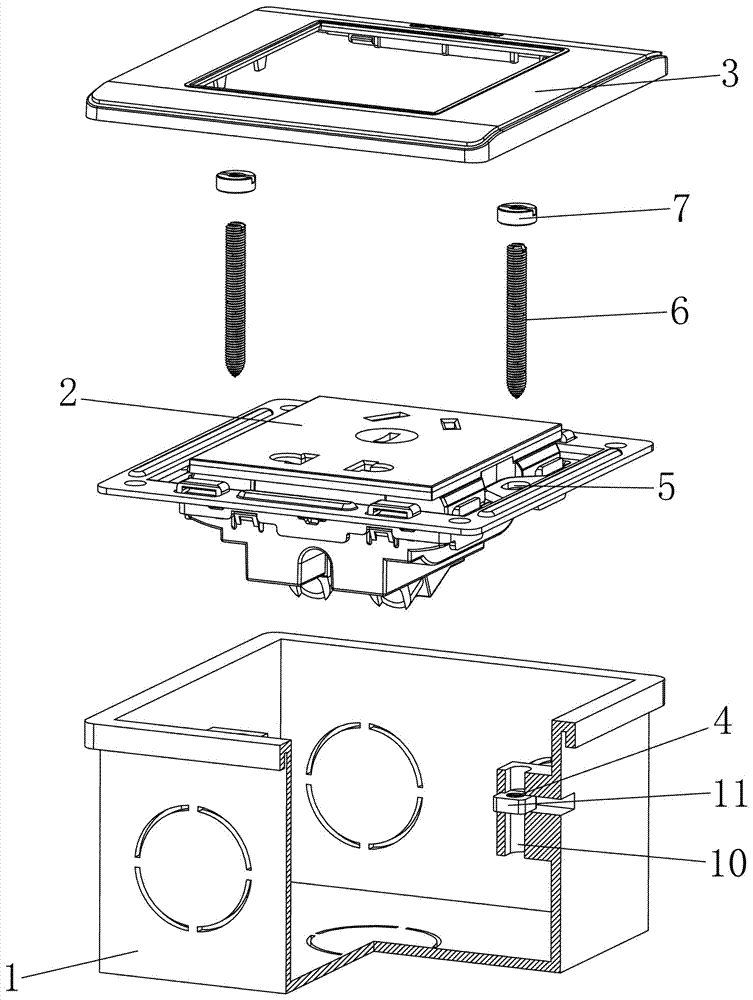

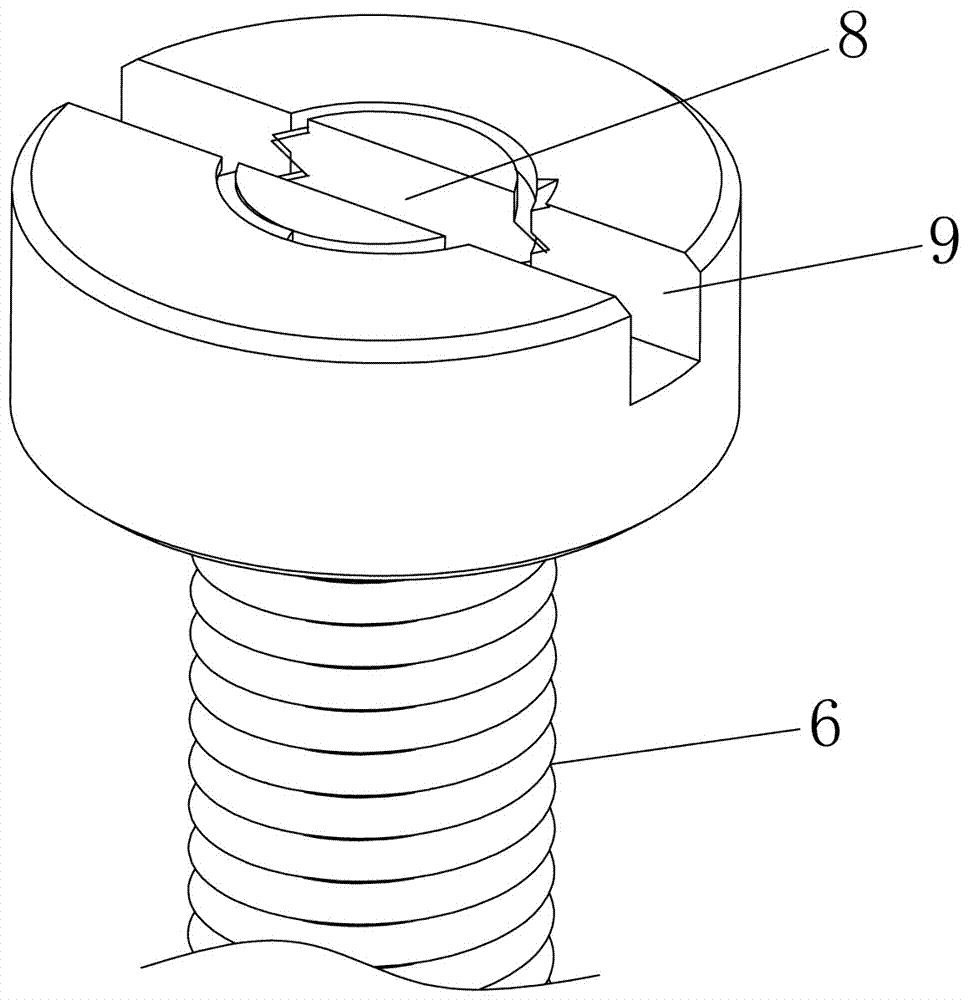

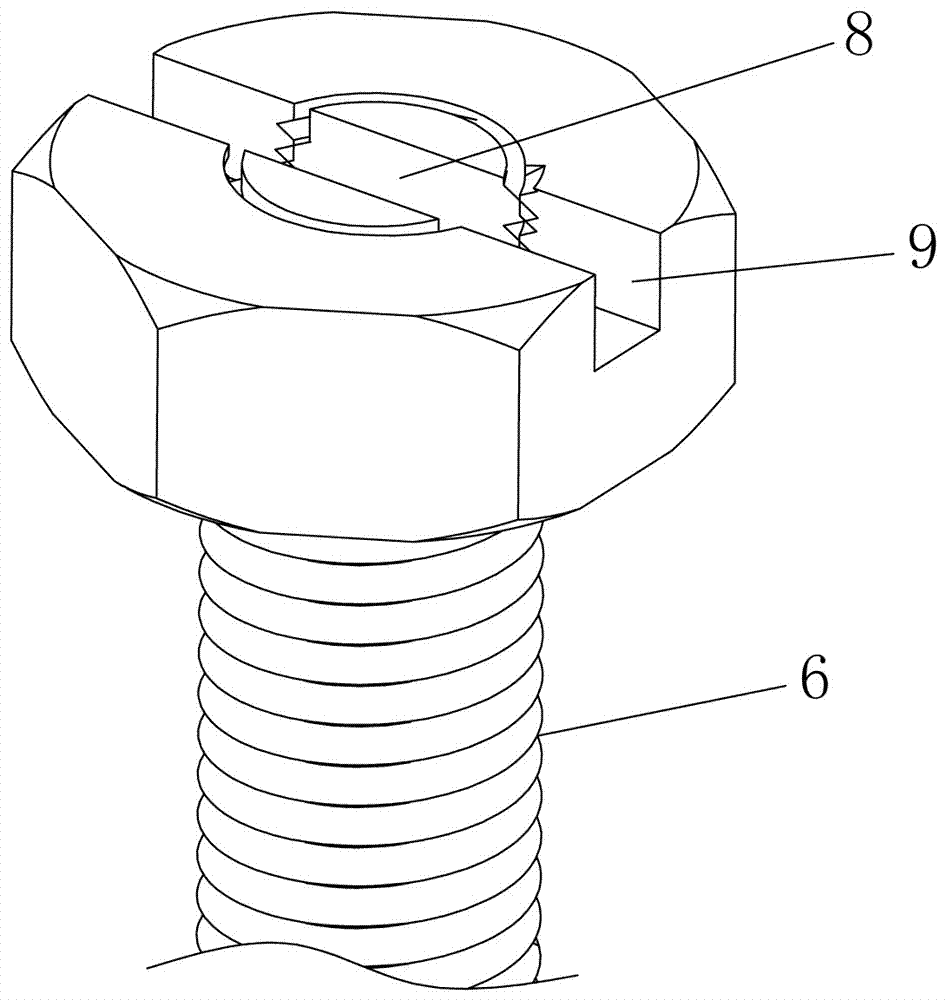

[0012] refer to Figure 1 to Figure 3 , an efficient installation structure for a switch socket panel and a bottom box, comprising a bottom box 1, a panel 2, a screw 6 and a face frame 3, the face frame 3 is fastened on the face plate 2, and the fastening of the face plate 2 and the face frame 3 The structure is the same as the fastening structure between the socket or the switch panel and the bottom box in the prior art. The bottom box 1 is provided with a screw hole 4, and the panel 2 is provided with a fixing hole 5, and the front end of the screw rod 6 is threadedly connected in the screw hole 4, and the panel 2 is packed into the bottom box 1 to make the screw rod 6 After the rear end passes through the fixing hole 5, a locking nut 7 is threadedly installed on the rear end of the screw rod 6, and a linkage structure is arranged on the locking nut 7 and the screw rod 6.

[0013] If the linkage structure is not provided, the exposed part of the screw rod 6 is too long and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com