Closed area high locking bolt installation method

An installation method and high-lock nut technology are applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve problems such as low production efficiency, inability to use high-lock bolts and fixed-torque wind turbines, and restrictions on the production and delivery of aircraft products. , to achieve the effect of improving the utilization rate, expanding the use of tools, and solving the low installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

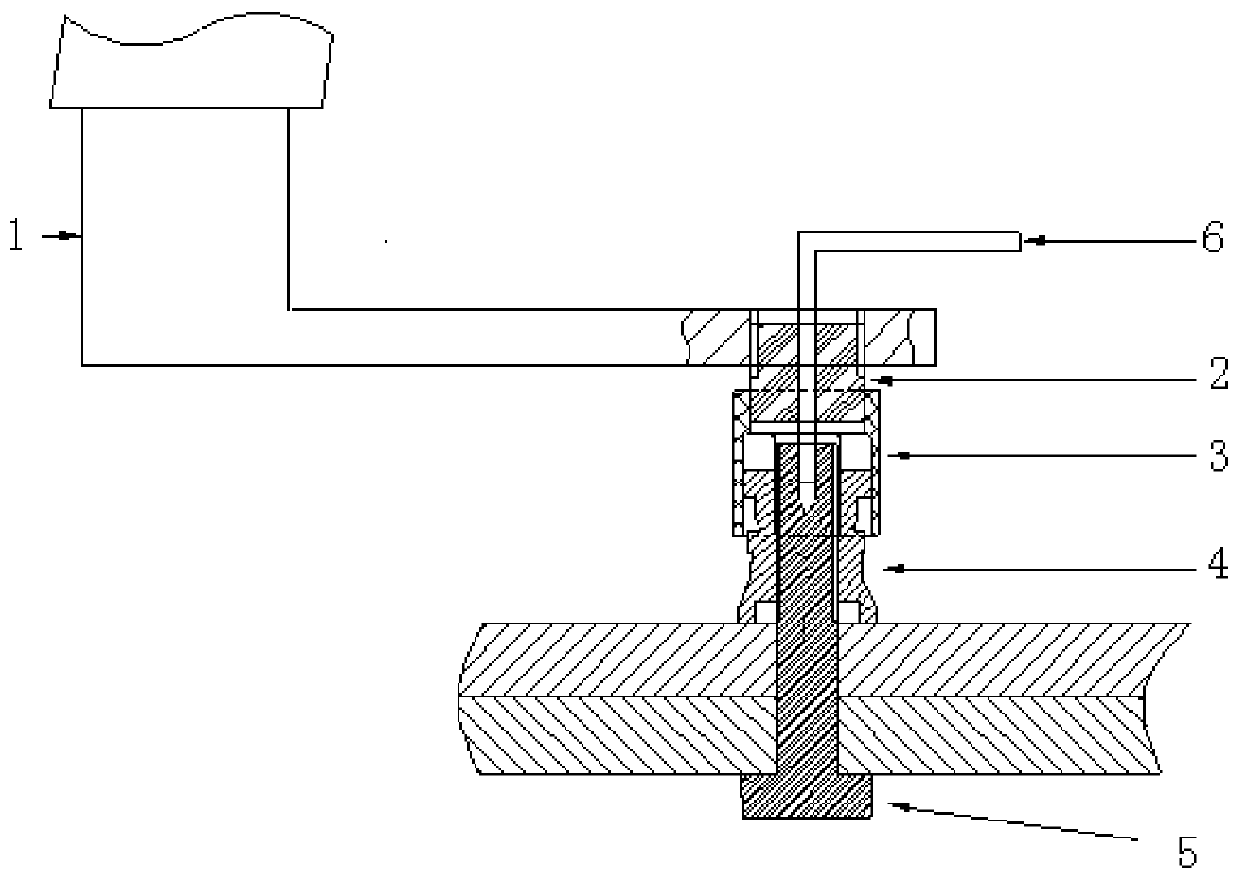

[0017] Such as figure 1 As shown, a method for installing high-lock bolts in closed areas uses a panel drill 1, adapter 2, sleeve 3, and hexagonal wrench 6 to install high-lock bolts 5. The specific installation includes the following steps:

[0018] 1 According to the product assembly space and the twisting torque value of the high lock nut 4 matched with the high lock bolt 5, the plate drill 1 is selected, and the torque of the plate drill 1 is greater than the twisting torque of the upper hexagon of the high lock nut 4;

[0019] In this example, according to the product assembly space (the structure is a closed bevel angle of 60°) and the twisting torque value of the high lock nut 4NTA11752-5 / NTA11752-6 (NTA11752-5 is 15-25IN.LbS; NTA11752-6 is 25- 35IN.LbS) selected a plate drill 1, the model is 17698, and the torque is 120IN.LbS. The included angle between the handle of the plate drill 1 and the rotating head is 17°, the rotating head can rotate 360 degrees with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com