Quick mounting type tool clamp for magnetic core

A tooling fixture and magnetic core technology, applied in inductor/transformer/magnet manufacturing, electrical components, circuits, etc., can solve problems such as low installation efficiency, achieve strong anti-vibration ability, facilitate mass production, and improve the effect of heat treatment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

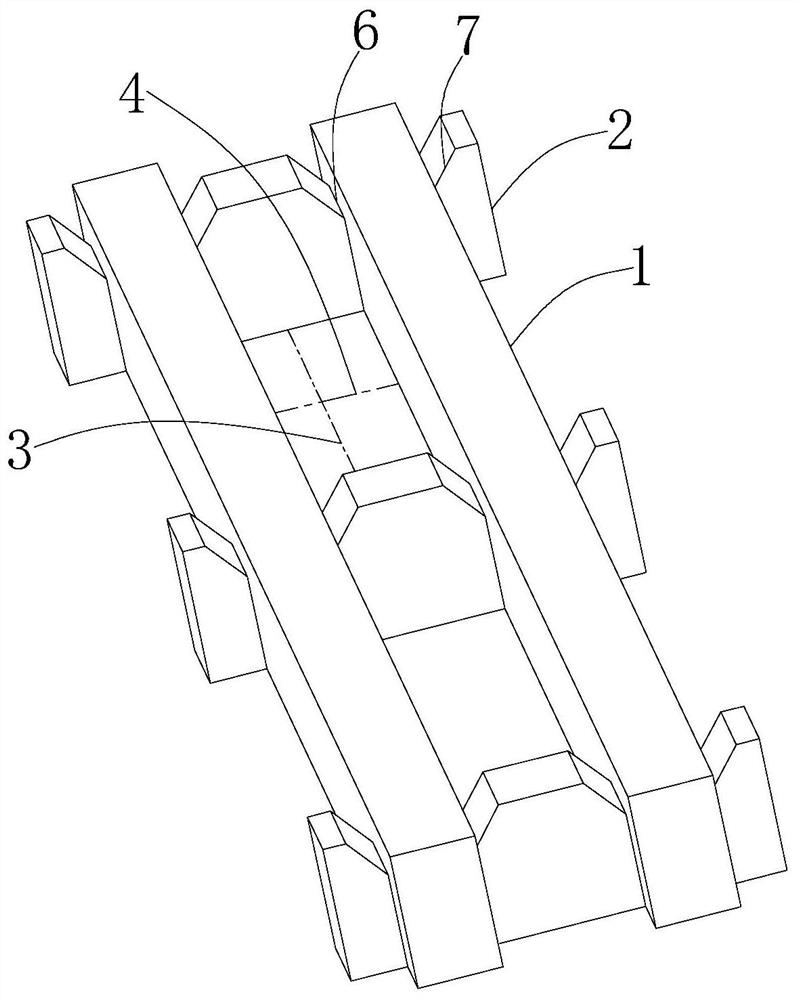

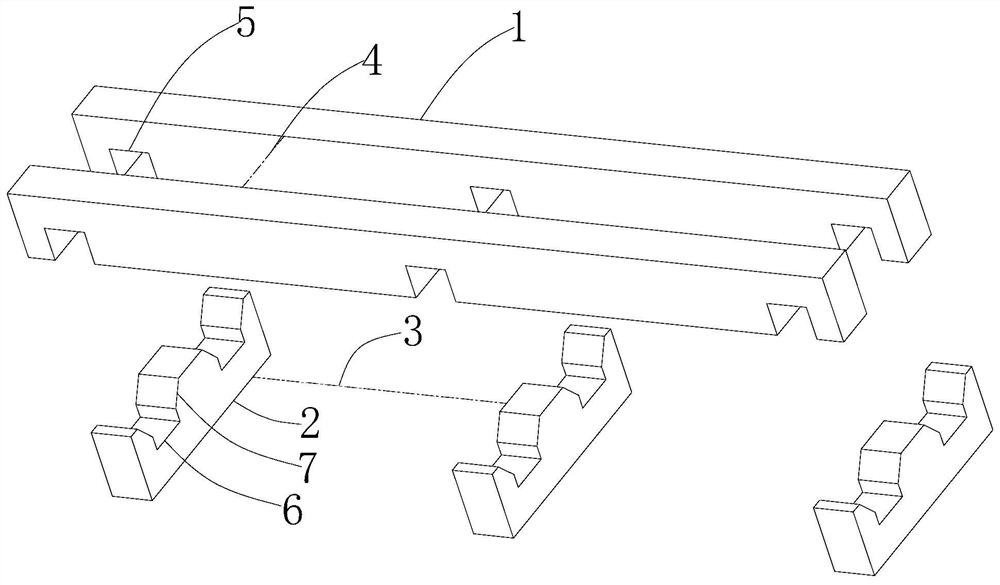

[0026] Embodiment: a kind of magnetic core fast installation type fixture, such as Figure 1 to Figure 2 As shown, there are at least two first connecting rods 1 and second connecting rods 2 in number, and there is a first installation position 3 matching the length of the magnetic core between two adjacent first connecting rods 1. A second mounting position 4 matching the width of the magnetic core is reserved between two adjacent second connecting rods 2 , and the first connecting rod 1 is detachably clamped on the second connecting rod 2 . The dotted lines in the figure indicate the first installation location 3 formed by two adjacent first connecting rods 1 and the second installation location 4 formed by two adjacent second connecting rods 2 .

[0027] In this scheme, the magnetic core is a racetrack-shaped magnetic core, and the first installation position 3 and the second installation position 4 constitute a square vacancy matching the racetrack-shaped magnetic core, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com