Wet oxidation catalyst

A wet oxidation and catalyst technology, used in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, oxidized water/sewage treatment, etc., can solve the problems of poor stability and low initial activity, and achieve stable The effect of improving sexual performance and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

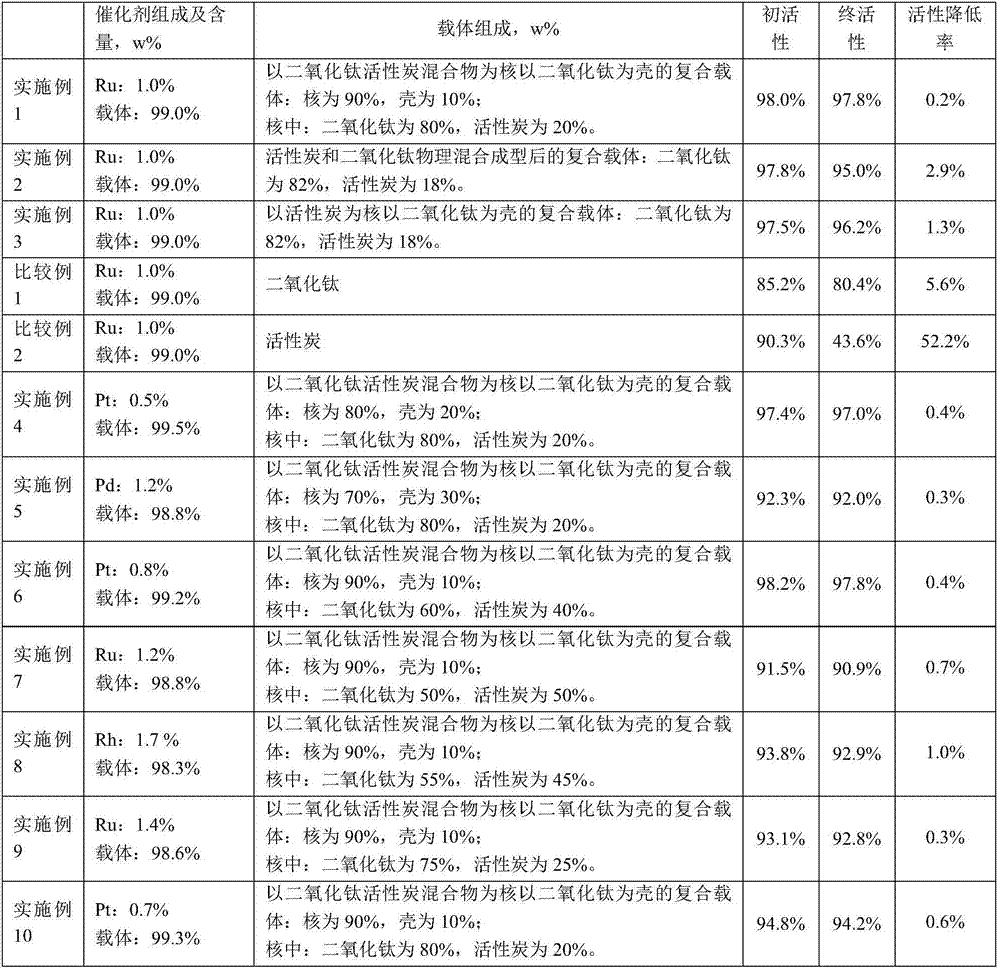

Examples

Embodiment 1

[0052] Catalyst preparation:

[0053] step 1)

[0054] Prepare 0.3mol / l TiOSO 4 Add 12g of activated carbon powder to 2000ml of aqueous solution, drop 0.6mol / l ammonia water into the turbid solution to co-precipitate to form a gel substance, filter, wash, dry, and roast at 300°C for 2 hours in a nitrogen atmosphere to obtain a composite carrier core pink;

[0055] Step 2)

[0056] 45g composite carrier nucleus powder, 0.1g n-butylamine and 0.1g oxalic acid are mixed, after kneading, extrusion, pelletizing, drying process, the nucleus of composite carrier is obtained; 50g titanium dioxide weight content is the sol spraying of 10% on On the core of the composite carrier, dry and bake at 850°C for 4 hours to make a composite carrier;

[0057] step 3)

[0058] 50g of the composite support was impregnated in a salt solution containing 0.50g of Ru. Immerse at room temperature for 6 hours, dry, and roast at 480°C for 2.5 hours to obtain a catalyst precursor; reduce the catalyst...

Embodiment 2

[0062] Catalyst preparation:

[0063] step 1)

[0064] Prepare 0.3mol / l TiOSO 4 2000ml aqueous solution, drop 0.6mol / l ammonia water into the turbid solution to co-precipitate to form a gel substance, filter, wash, dry, and roast at 300°C for 2 hours under a nitrogen atmosphere to obtain titanium dioxide powder;

[0065] Step 2)

[0066] Mix 41g of titanium dioxide powder, 9g of activated carbon powder, 0.1g of n-butylamine and 0.1g of oxalic acid, knead, extrude, pelletize, and dry, then bake at 850°C for 4 hours to make a composite carrier;

[0067] step 3)

[0068] 50g of the composite support was impregnated in a salt solution containing 0.50g of Ru. Immerse at room temperature for 6 hours, dry, and roast at 480°C for 2.5 hours to obtain a catalyst precursor; reduce the catalyst precursor with hydrogen at 400°C for 3 hours to obtain a finished catalyst;

[0069] Catalyst Evaluation:

[0070] The catalyst prepared above is loaded into a wet oxidation reactor, and the ...

Embodiment 3

[0072] step 1)

[0073] Mix 9g of the composite carrier core powder described in step 1) of Example 1, 0.02g of n-butylamine and 0.02g of oxalic acid, and after kneading, extruding, pelletizing and drying, roast at 300°C for 2 hours in a nitrogen atmosphere , making the core of the composite carrier;

[0074] Step 2)

[0075] 410g of titanium dioxide with a weight content of 10% was sprayed on the core of 9g of the composite carrier several times, and after drying, it was baked at 850°C for 4 hours to make the composite carrier;

[0076] step 3)

[0077] 50g of the composite support was impregnated in a salt solution containing 0.50g of Ru. Immerse at room temperature for 6 hours, dry, and roast at 480°C for 2.5 hours to obtain a catalyst precursor; reduce the catalyst precursor with hydrogen at 400°C for 3 hours to obtain a finished catalyst;

[0078] Catalyst Evaluation:

[0079] The catalyst prepared above is loaded into a wet oxidation reactor, and the waste water is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com