A kind of breathable surgical gloves and preparation method thereof

A technology for gloves and surgery, applied in the field of surgical gloves, can solve the problems of unfavorable market promotion, high cost of raw materials, poor moisture permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of breathable surgical gloves, comprising the following steps:

[0022] The water-based polyurethane resin material is mixed with water and stirred to obtain a mixed solution; the water-based polyurethane resin material includes 15 to 50 parts by weight of polyurethane and 50 to 85 parts by weight of water; the polyurethane consists of a mass ratio of 30 to 50: 15~25: 1~10: 0.5~20: 0.1~10: 0.1~0.5: 1~10: 1~10 polyol polymer, diisocyanate, water-based chain extender, hydrophilic agent, crosslinking agent, catalyst , a salt-forming agent and an organic solvent; the polymer is selected from polyols selected from polyether polyols and / or polyester polyols;

[0023] Dip the hand mold into the mixed solution, curl the lip after forming a film, and demould to obtain a breathable surgical glove;

[0024] The temperature of the hand mold during the dipping is ≤60°C, the dipping time is 20-60s; the film-forming temperature is 1...

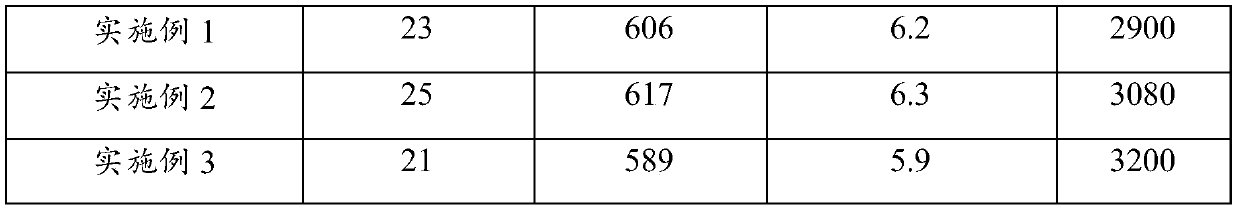

Embodiment 1

[0055] Add 33 parts of polytetrahydrofuran ether glycol (PTMG-1000) into the reaction kettle, heat up to 80-90°C while stirring, dehydrate with a vacuum pump for 1 hour, and then add isophorone diisocyanate (IPDI) (diisocyanate) 22 parts were incubated at 80°C for 1 hour to obtain an intermediate;

[0056] Then weigh 2.5 parts of dimethylolpropionic acid (DMPA) (hydrophilic agent) and add 3.0 parts of diethylene glycol chain extender into the kettle together, stir well and then add 20 parts of acetone low boiling point solvent, 0.01 part of dilaurel Acetate dibutyltin catalyst, at 50-80°C, react for 3 hours; then add 1.6 parts of trimethylolpropane (TMP) cross-linking agent, 25 parts of acetone, react for 3 hours, the reaction is completed, lower the temperature to below 50°C, add 33 parts of acetone and 3 parts of triethanolamine salt-forming agent, add 185 parts of deionized water after cooling down, and disperse the polyurethane polymer at a speed of 500-1000 r / min with a h...

Embodiment 2

[0070] Add 50 parts of polytetrahydrofuran ether glycol (PTMG-1500) into the reaction kettle, stir while raising the temperature to 80-90°C, dehydrate with a vacuum pump for 1 hour, and then add isophorone diisocyanate (diisocyanate) (IPDI) 22 Parts were incubated at 80°C for 1 hour to obtain an intermediate;

[0071] Then weigh 2.5 parts of dimethylol propionic acid (DMPA) and 3.0 parts of diethylene glycol chain extender and add them into the kettle together, stir evenly, then add 20 parts of acetone low boiling point solvent and 0.01 part of dibutyltin dilaurate catalyst. At 50-80°C, react for 3 hours. Then add 1.6 parts of trimethylolpropane (TMP) cross-linking agent, 25 parts of acetone, and time the reaction for 3 hours. After the reaction is over, lower the temperature to below 50°C, add 33 parts of acetone and 3 parts of triethanolamine salt forming agent, add 185 parts of deionized water after cooling down, and disperse the polyurethane polymer at a speed of 500-1000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com