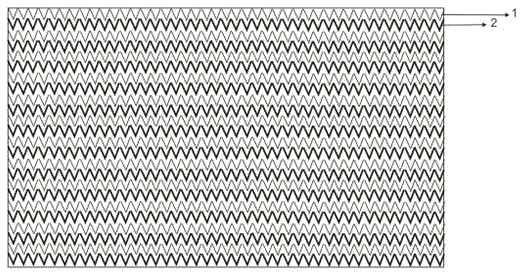

Purified cotton knitted fabric having soft hemp effect and manufacturing method thereof

A production method and technology of knitted fabrics, which are applied in the field of textile fabrics, can solve problems such as easy fluffing, poor wrinkle recovery ability, and difficult twisting, etc., and achieve the effects of eliminating easy fluffing, good air permeability, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

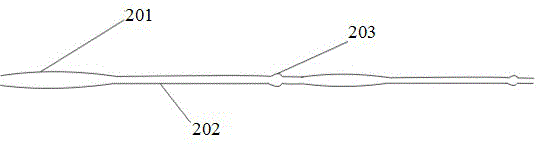

[0017] The knotted yarn of the present example can be made by following method: add a set of lifting device between the middle roller and the back roller of FA506 spinning frame, have sawtooth guide rod on this lifting device. During spinning, feed two rovings at the same time, the two rovings are respectively the first roving and the second roving, and the first roving and the second roving are respectively unwound from the second roving bobbin and the first roving bobbin of the FA506 spinning frame Down, enter the yarn guide horn through the first yarn guide rod and the second yarn guide rod of FA506 spinning frame in turn, and the first roving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com