A kind of cellulose composite waterproof film and preparation method thereof

A waterproof film, cellulose technology, applied in the direction of flat products, other household appliances, coatings, etc., can solve the problems of limited use range, poor mechanical properties of polyester and polyurethane film moisture permeability, long synthesis route, etc. The effect of avoiding the reduction of moisture permeability, excellent moisture permeability, and controllable moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

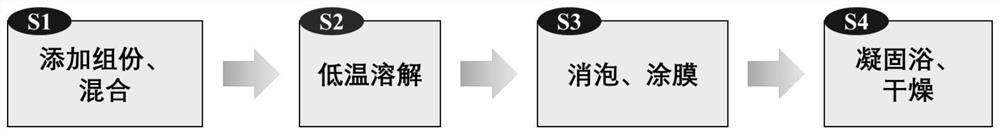

[0035] The application also provides the preparation method of the cellulose composite waterproof film, such as figure 1 As shown, it specifically includes the following steps:

[0036] A) dissolving 70-100 parts by weight of cellulose pulp, 0-20 parts by weight of ultrafine functional materials and 0-10 parts by weight of additives in the solution, and stirring to obtain a cellulose solution;

[0037] B) Degassing the cellulose solution and forming a film to obtain an initial cellulose film;

[0038] C) coagulating and exchanging the cellulose initial film in a coagulation bath, and obtaining a cellulose composite waterproof film after drying.

[0039] The cellulose composite waterproof film prepared by the present application does not have a porous structure, so there will be no clogging of micropores during use, thereby avoiding the problem of lower moisture permeability in later use.

[0040] In the above-mentioned specific preparation process, firstly, the cellulose pul...

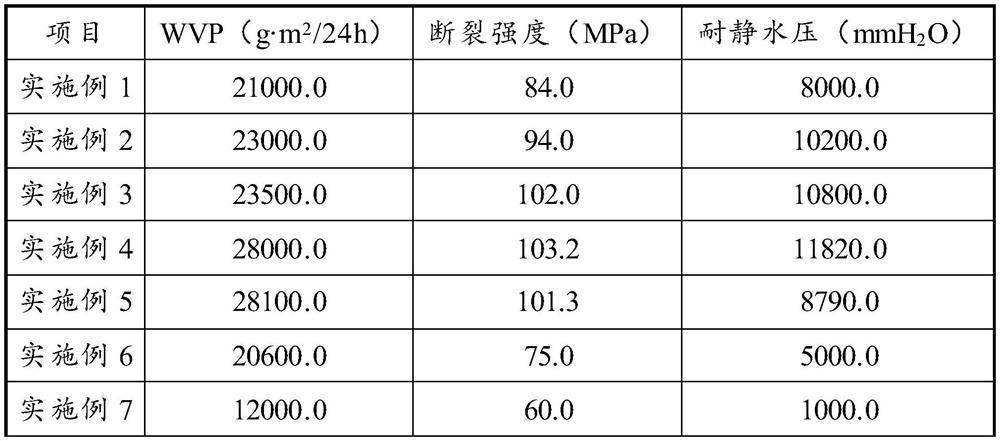

Embodiment 1

[0047] A cellulose and cellulose composite material waterproof film with high moisture permeability and a preparation method thereof, comprising the following steps (the following parts and proportions not specially marked are all parts by weight):

[0048] Preparation of cellulose waterproof and moisture-permeable film: add 100 parts of absorbent cotton to the container, add a certain amount of sodium hydroxide (10%)-urea (19%) mixed aqueous solution, and prepare a absorbent cotton mixture with a solid content of 5%. Stir the absorbent cotton mixture at 25°C with a rotation speed of 800rpm until it is completely dissolved, and then use an ultracentrifuge to remove air bubbles to obtain a cellulose solution with good transparency; Coating process), then put the wet film into 15°C, 90% ethanol aqueous solution for ion exchange and regeneration, take it out after 12 hours, rinse it with water, and then dry it in an oven at 30°C for 24 hours to prepare the thickness 0.01mm high m...

Embodiment 2

[0050] A cellulose and cellulose composite material waterproof film with high moisture permeability and a preparation method thereof, comprising the following steps (the following parts and proportions not specially marked are all parts by weight):

[0051] Preparation of carbon black-cellulose composite material waterproof and moisture-permeable film: add 99 parts of absorbent cotton, 1 part of carbon black particles (specification: 2 μm) in the container, and then add a certain amount of sodium hydroxide (10%)-urea (19% ) mixed aqueous solution to prepare a absorbent cotton-carbon black mixture with a solid content of 5%, stir the absorbent cotton mixture at -25°C and a rotating speed of 800rpm until it is completely dissolved, and then use an ultracentrifuge to remove air bubbles to obtain a cellulose solution with good transparency , and then use a wire rod (specification: 20 μm) to make a wet film (coating process) on a glass plate, then put the wet film in 15 ° C, 90% eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com