Automatic closing structure for sliding cover

An automatic closing and sliding cover technology, applied in building construction, building locks, buildings, etc., can solve the problems of stuck position, safety accident, fingers caught in the gap, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

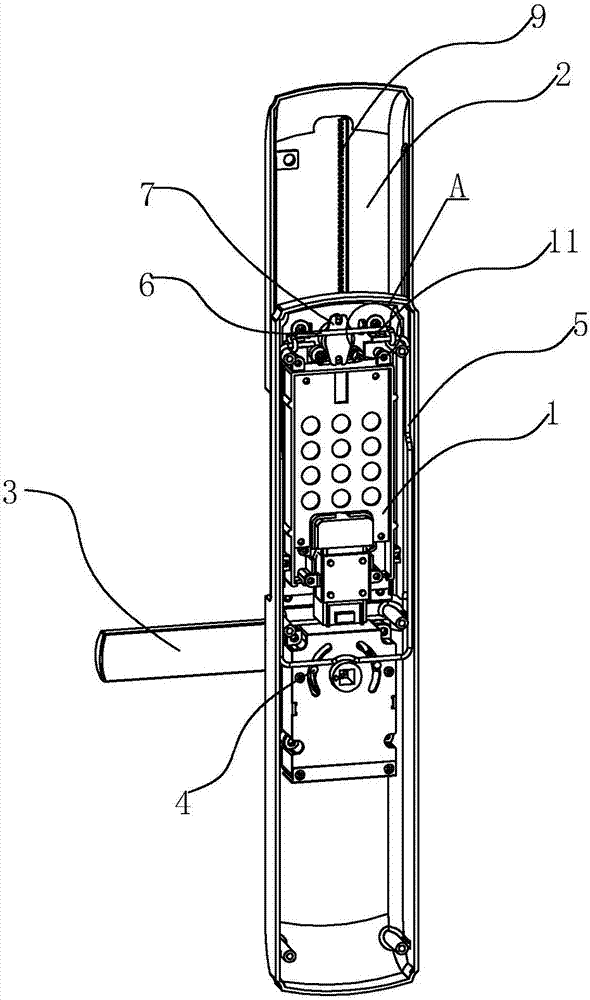

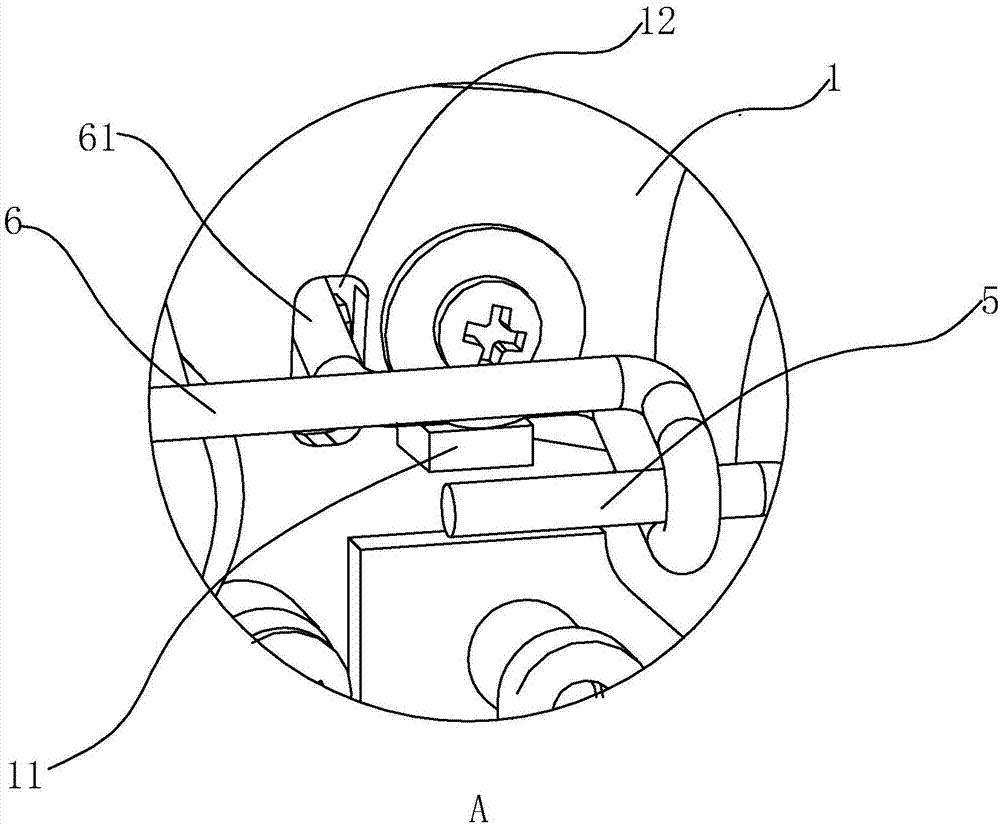

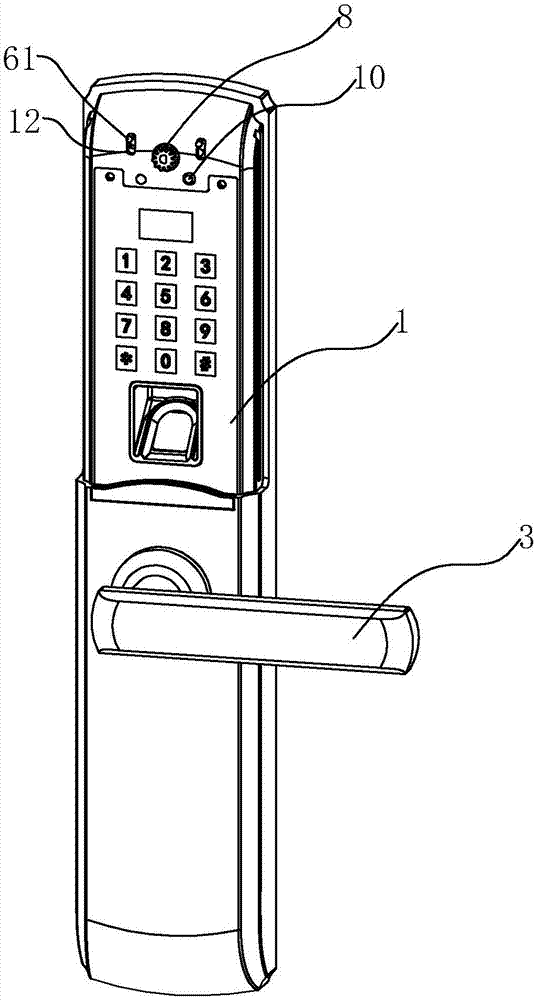

[0016] Refer to attached Figure 1 to Figure 4 A sliding cover automatic closing structure of the present invention will be further described in detail.

[0017] A sliding cover automatic closing structure, comprising a door lock main body 1, a sliding cover 2 and a handle 3; one end of the handle 3 is rotatably arranged on the door lock main body 1, and the end is provided with a rotating column 4, A push rod 5 is arranged above the rotating column 4; one end of the pushing rod 5 abuts on the rotating column 4, and the other end is linked with a shift fork 6, and the door lock main body 1 is provided with a shift fork. 6, the swing fulcrum 11, the shift fork 6 is provided with a hook 61, and the push rod 5 moves upward to push the hook 61 of the shift fork 6 to swing downward around the swing fulcrum 11;

[0018] The door lock main body 1 is provided with a toggle chute 12, and the hook 61 passes through the toggle chute 12 to be connected with the slide cover 2; the door lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com