Closed wood grinding device for furniture production

A closed, furniture technology, used in grinding machines, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of low work efficiency, long time consumption, endangering workers' lives, safety and health, etc., to achieve the effect of reasonable design and avoidance of breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

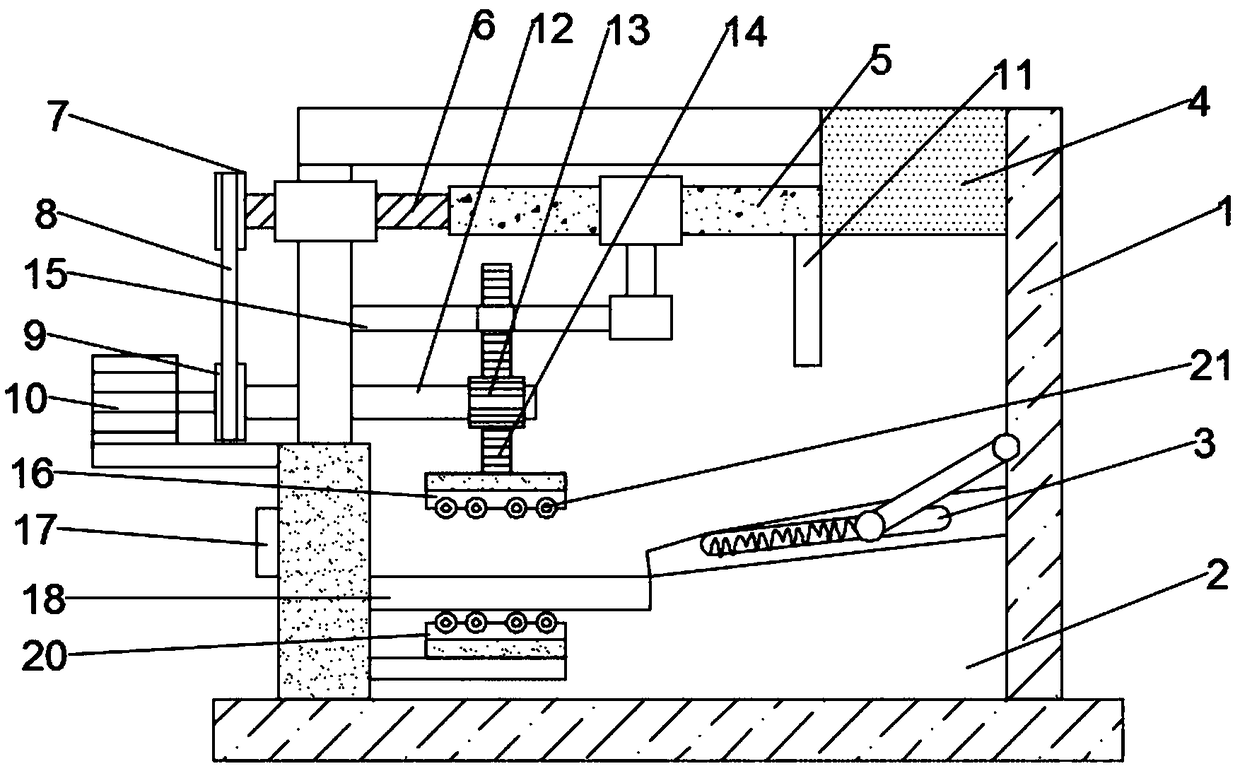

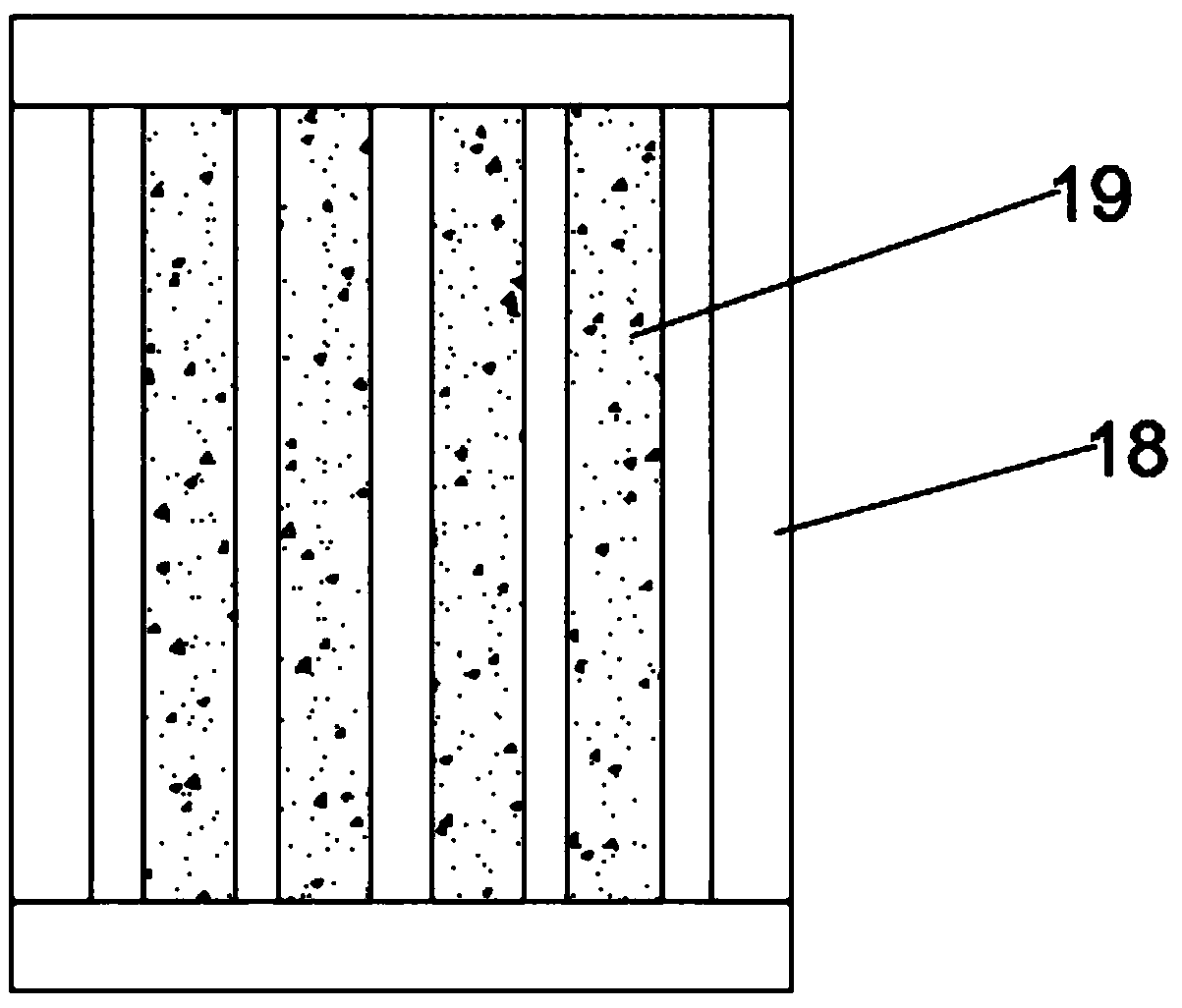

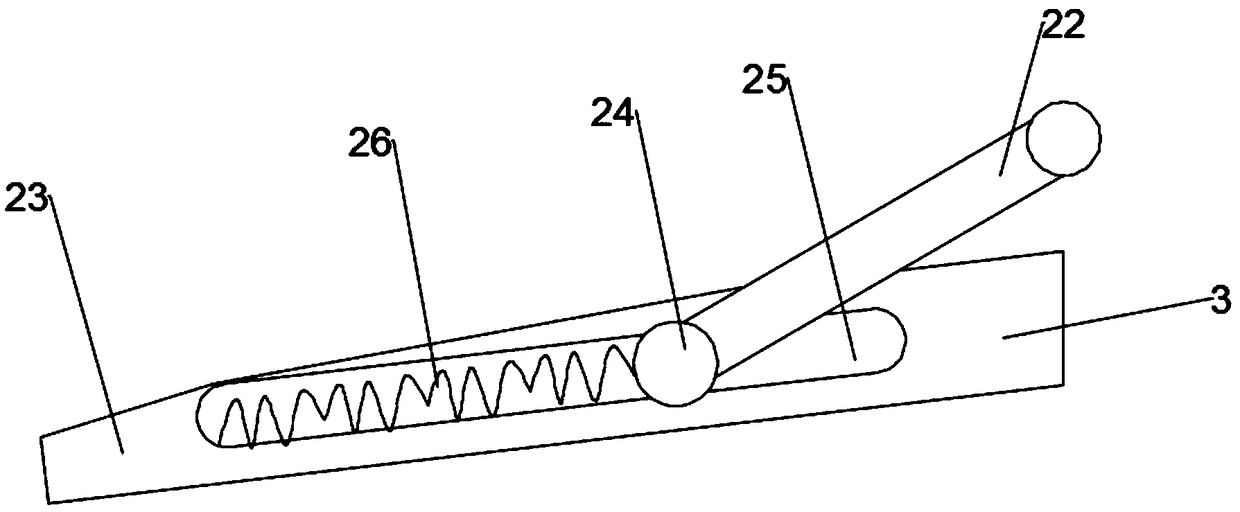

[0023] see Figure 1~3, in an embodiment of the present invention, a kind of wood grinding device for closed furniture production, comprising a closed housing 1, a grinding chamber 2, a buffer assembly 3, a feeding channel 4 and a grinding support plate 18, the inside of the closed housing 1 is set Grinding chamber 2, the upper right of the grinding chamber 2 is provided with a feeding channel 4, the grinding chamber 2 communicates with the feeding channel 4, and a buffer assembly 3 is arranged below the feeding channel 4, and the buffer assembly 3 is installed on On the inner wall of the grinding chamber 2, a grinding support plate 18 is arranged horizontally on the left side of the buffer assembly 3. The inside of the grinding support plate 18 is a hollow structure, and the left end of the grinding support plate 18 is welded to the left side of the closed casing 1. Side wall, the lower part of the left side wall of the closed housing 1 is provided with a discharge port 17, t...

Embodiment 2

[0025] see Figure 4 , different from Embodiment 1, the return spring 26 in the buffer assembly 3 is arranged at the middle position between the second inclined material guide plate 23 and the right side wall of the closed casing 1, and the return spring 26 is respectively connected to the The second inclined material guide plate 23 is hinged to the right side wall of the closed casing 1, and the setting of the return spring 26 can also realize sufficient buffer protection for wood,

[0026] The working principle of the present invention is: the servo motor 10 starts forward and reverse, can drive the rotating shaft 12 and the second runner 9 to rotate, and then makes the second runner 9 drive the first runner 7 and the screw thread The rod 6 rotates, so that the automatic baffle 5 moves left and right along the threaded rod 6, thereby realizing the automatic closing of the feeding channel 4, thereby helping to realize the automatic feeding of the planks and avoiding the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com