Working method of lithium battery assembling device

A technology of assembling device and working method, which is applied in the directions of non-aqueous electrolyte storage battery, electrolyte storage battery manufacturing, and manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

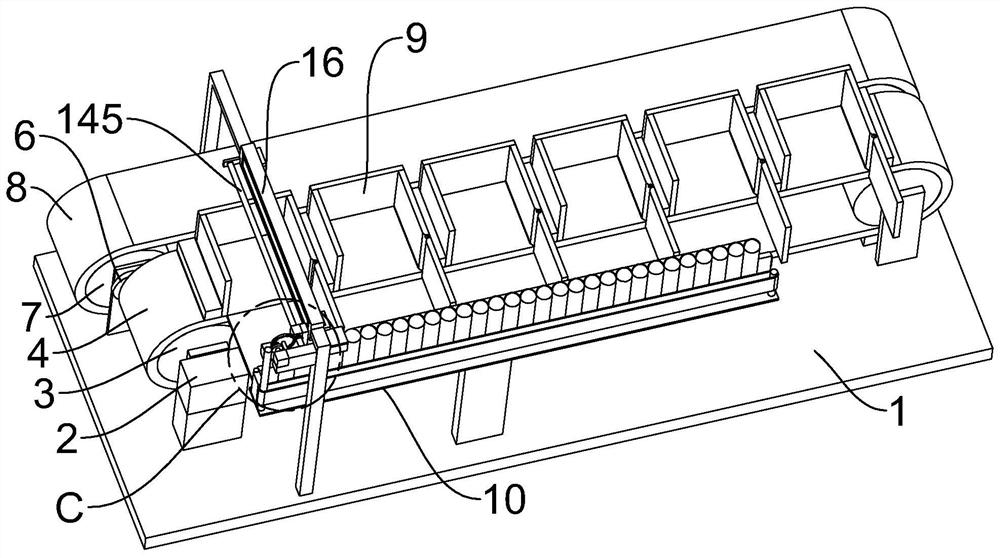

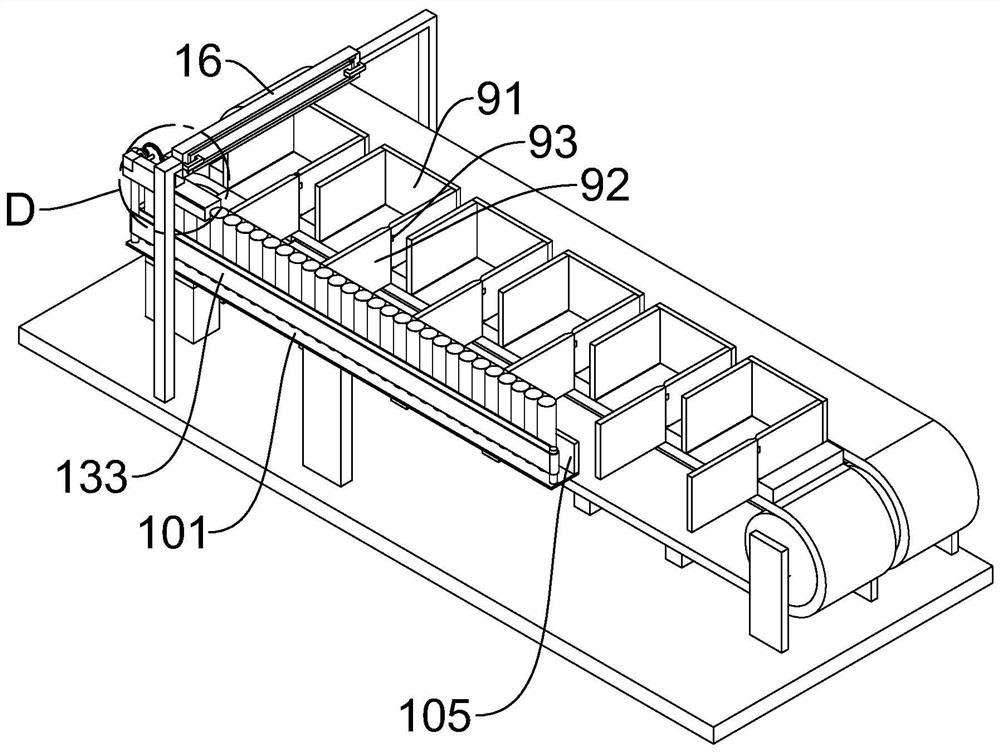

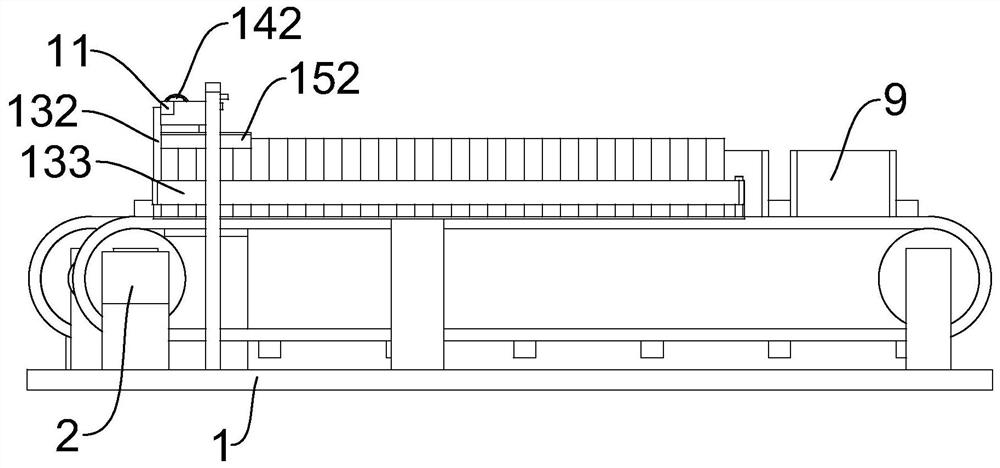

[0028]Such asFigure 1 to Figure 13 As shown, a working method of a lithium battery assembling device includes a base 1 and a first stepping motor 2 arranged at the upper end of the base 1. The left and right sides above the base 1 are provided with first transfer rollers 3, The second conveying roller 7 behind the first conveying roller 3, the output shaft of the first stepping motor 2 is keyed with the first conveying roller 3 on the left side, a first conveying belt 4 is connected between the two first conveying rollers 3, A conveyor belt 4 is equidistantly arranged with spacers for spacing and positioning the fixed frame 9, a second conveyor belt 8 is connected between the two second conveyor rollers 7, and the first conveyor roller 3 and the second conveyor roller 7 on the left The first transmission gear 5 and the second transmission gear 6 are respectively keyed with each other. The upper part of the base 1 is provided with a conveying member 10 that is flush with the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com