Shoe sole structure wearable in four seasons based on exhaust holes

A technology of air vents and air holes, which is applied in the field of four-season available sole structures, can solve the problems of being unsuitable for large-scale production, high cost, and low cost, and achieve the effects of low production cost, simple structure, and improved general performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

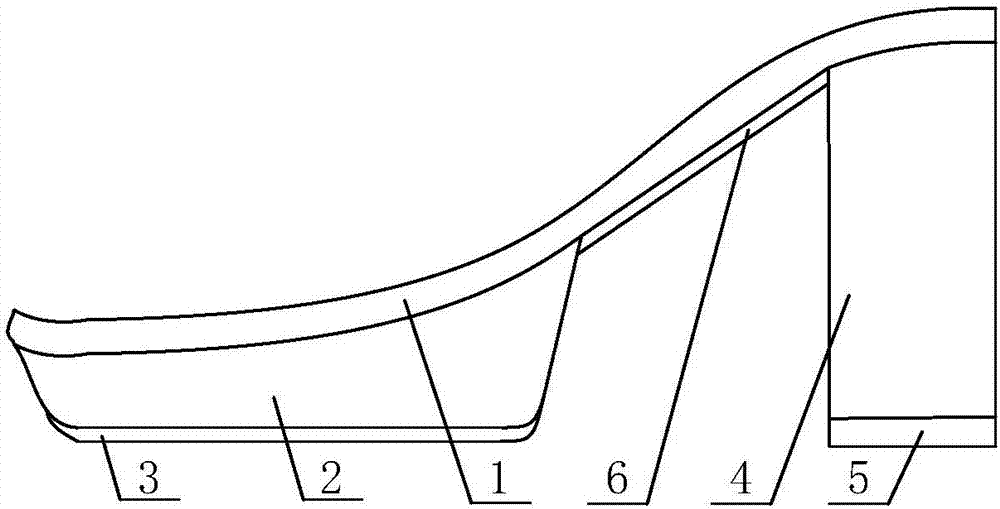

[0024] A four-season sole structure based on air vents, such as Figure 1-Figure 2 As shown, it includes a midsole 1, a waterproof platform 2 arranged at the front position of the midsole 1, an outsole 3 arranged at the bottom of the waterproof platform 2, a heel 4 arranged at the rear position of the midsole 1, and a heel 4 arranged at the heel 4 The sky skin at the bottom 5.

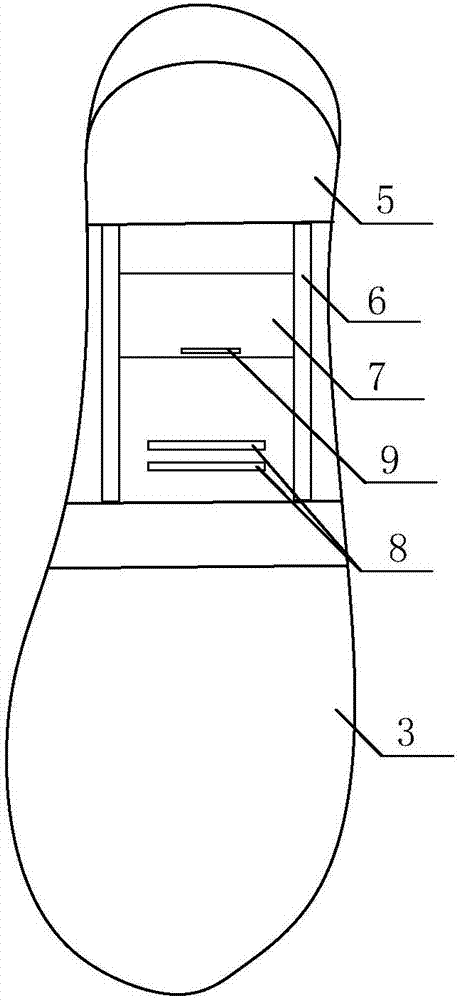

[0025] The waist position of the midsole 1 is provided with an air vent 8 that runs through the midsole 1, and fixed chute 6 is provided on both sides of the bottom surface of the midsole 1 below the air vent 8, and the fixed chute 6 is also provided with a useful It is used to block the sliding baffle plate 7 of the ventilation hole 8.

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is that the structure of the air vent 8, the fixed chute 6 and the sliding baffle 7 is optimized, and the specific settings are as follows:

[0028] The air holes 8 are long strips, the length is 1 / 2-2 / 3 of the width of the midsole 1, and the width is 2-5mm. In this embodiment, the number of the air holes 8 is two, and the width of each air hole 8 is 2-3 mm.

Embodiment 3

[0030] The difference between this embodiment and Embodiment 1 is that in this embodiment, the structure at the position of the fixed chute 6 is optimized, and the specific settings are as follows:

[0031] The fixed chute 6 is composed of two symmetrical concave pieces opposite to each other in the opening direction. One side of the sliding baffle 7 extends into one of the concave parts, and the opposite side of the sliding baffle 7 extends into the other concave part; the remaining two sides of the sliding baffle 7 are provided with wind-blocking strips . The concave part is made of stainless steel. The wind blocking strip is made of rubber material.

[0032] The bottom end of the midsole 1 is provided with a groove, and the fixed sliding groove 6 is installed in the groove. The sliding baffle 7 is provided with a bump that is convenient for manually moving the position of the sliding baffle 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com