Mold assembly and closing method of mold assembly

A mold and component technology, which is applied in the stamping die component and the closing field of the stamping die component, can solve the problems of high expenditure cost, time-consuming and laborious, manual replacement, etc., and achieve the effect of fast speed, cumbersome solution process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] S1, mold disassembly: the top mold and the bottom mold are disassembled by external tools. When disassembling, manually through multiple sets of different types of external tools, the different types of locking components and screws on the plastic mold are respectively removed. manual removal;

[0039] S2, mold installation; the corresponding plastic molds are installed and fixed on the top mold and the bottom mold respectively through external tools. When installing, the plastic molds are placed on the top mold and bottom mold respectively, and the external tools are used to shape the molds respectively. Different types of locking components and screws on the mold are manually installed. According to S1 and S2, if one person replaces it, it takes about 20-25 minutes. If two people replace the top mold and bottom mold at the same time, it takes about 20 minutes. 10-14min;

[0040] S3, closed stamping: the stamping material is placed on the molding die of the bottom die...

Embodiment 2

[0043] S1, mold replacement: select the mold that matches the plastic mold and the stamping type, connect the electronic components on the mold and connect the control terminal to the external power supply, the connection of the electronic components and the power connection of the control terminal takes about 1-2min, only need It can be done by one person;

[0044] S2, closed stamping: the stamping material is placed on the molding die of the bottom die, and the top die is driven by the cylinder. After the molding die on the top die is in contact with the stamping material on the bottom die, the stamping force is used to achieve shaping;

[0045] S3, separation and reclaiming: after the molding is completed, the top mold is driven to reset by the air cylinder, the molded material is taken out, and the edge material is cleaned.

Embodiment 3

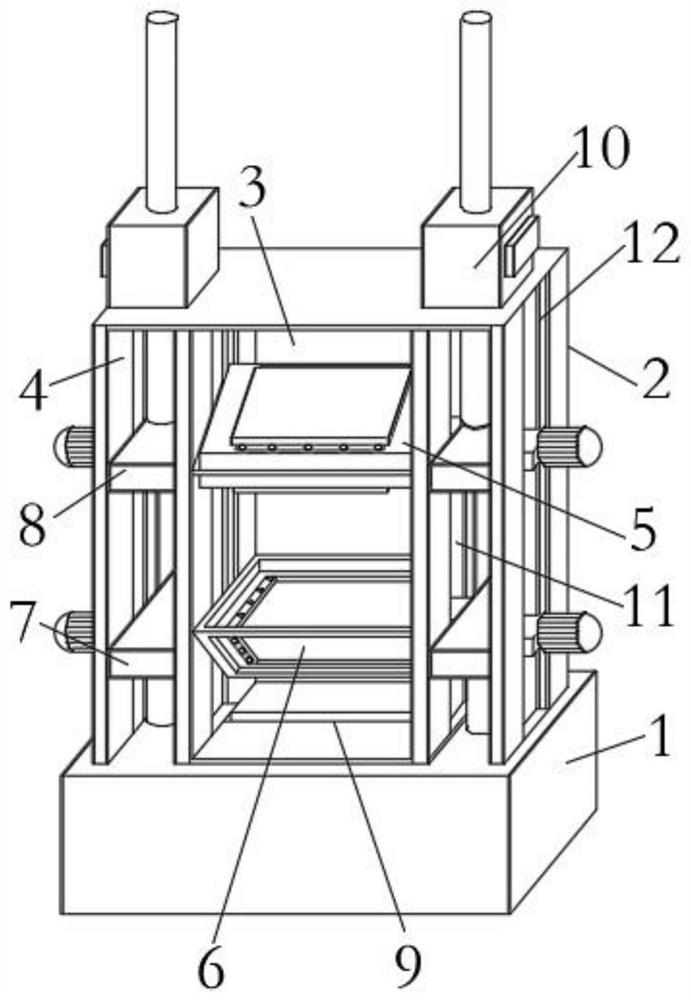

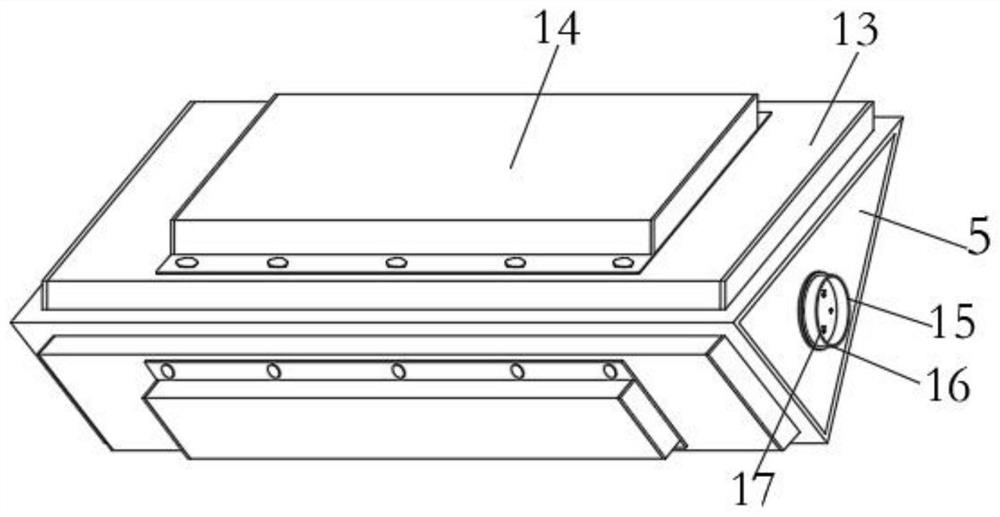

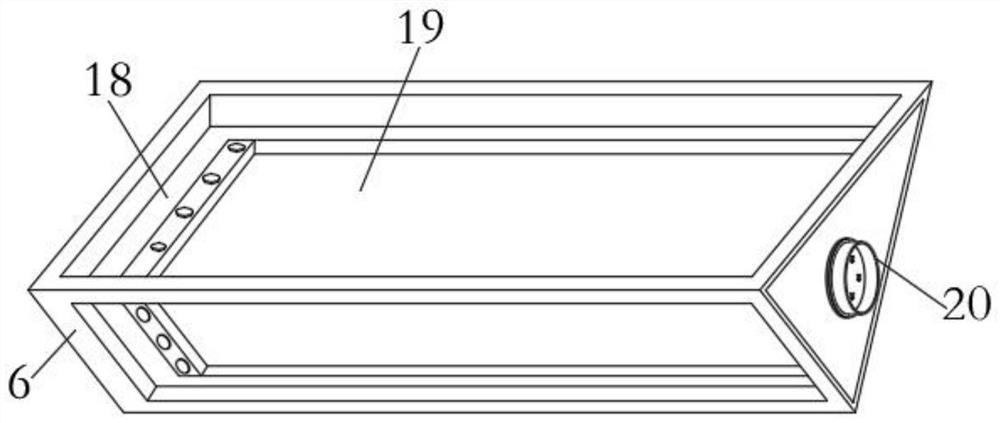

[0047] S1, Die adjustment: According to the current type of pre-stamping, it is necessary to adjust the molding die corresponding to the pre-stamping type on the top die 5 and the bottom die 6 to the stamping position, and move the bottom die 6 out of the limit slot by the hydraulic push rod 31 9. Start the motor 23 on the first transmission block 7 and the second transmission block 8 respectively, and drive the rotation of the top mold 5 and the bottom mold 6 respectively through the motor 23 through the rotating assembly 25, so that the position adjustment can be realized. The whole process takes about 3-5min, only one person can complete it through the control terminal;

[0048] S2, closed stamping: the stamping material is placed on the shaping die of the bottom die 6, and the top die 5 is driven by the cylinder 10. After the shaping die on the top die 5 is in contact with the stamping material on the bottom die 6, the stamping pressure shape;

[0049] S3, separating and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com