Dust collection assembly and dust collector

A technology for vacuum cleaners and components, applied in vacuum cleaners, suction nozzles, household appliances, etc., can solve problems such as inconvenient switching modes, damage, and failure to work, and achieve the effects of improving user experience, preventing loss, and reducing accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

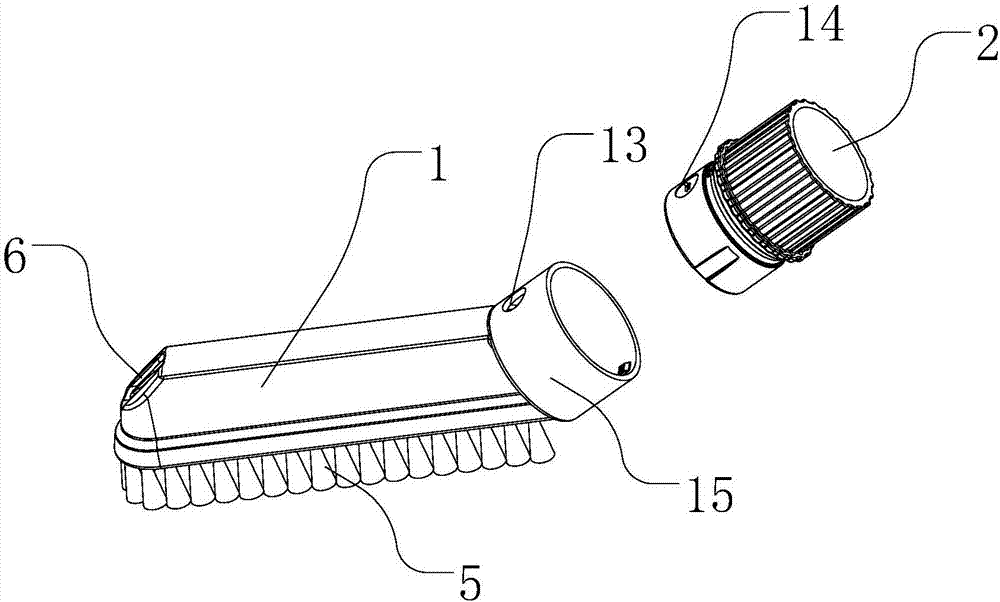

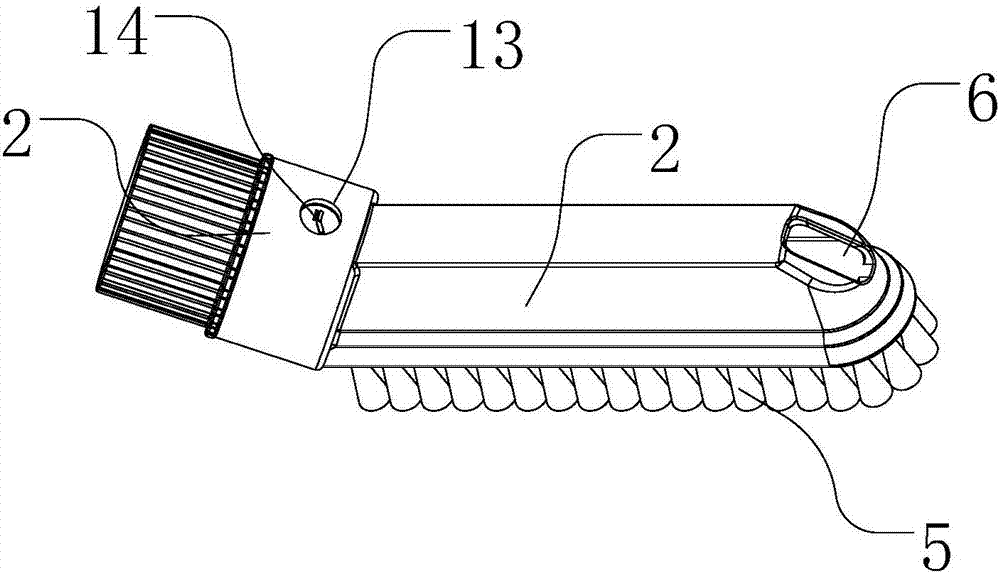

[0053] Such as Figure 1 to Figure 10 As shown, it is the dust collection assembly disclosed in this embodiment, which includes a dust suction head 1 and a joint pipe 2. The joint pipe 2 is respectively connected to the dust suction head 1 and the dust suction pipe of the vacuum cleaner. During the working process of the vacuum cleaner, air and dust particles pass through The dust suction head 1, the joint pipe 2 and the dust suction pipe enter into the accommodating cavity of the vacuum cleaner for storing dust.

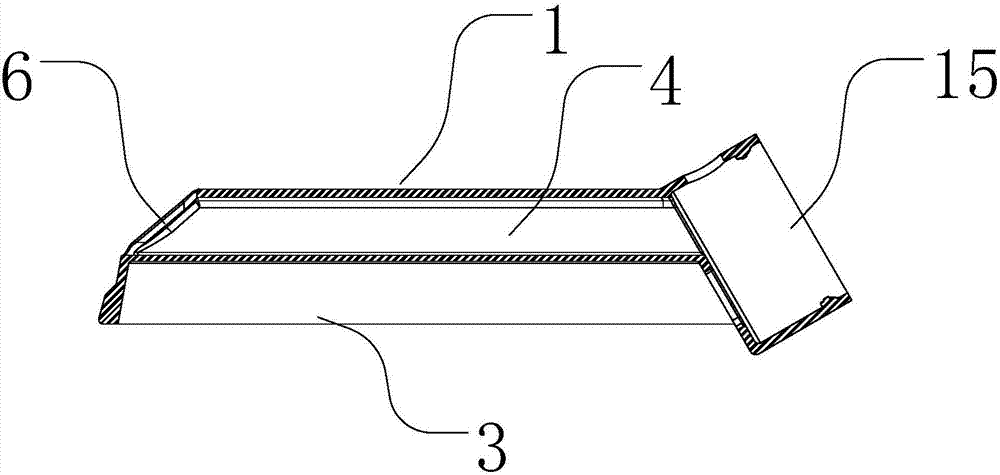

[0054] The cleaning head 1 is provided with a wide brush 5 and a flat suction port 6 to realize the purpose of integrating the wide brush 5 and the flat suction port 6 as two accessories in the prior art, as image 3 , Figure 5 shown. There is a wide brush dust suction channel 3 and a flat suction dust suction channel 4 inside the dust suction head 1 , the wide brush dust suction channel 3 communicates with the wide brush 5 , and the flat suction dust suction cha...

Embodiment 2

[0070] This embodiment discloses a vacuum cleaner. The vacuum cleaner in this embodiment is provided with the dust collection assembly described in the first embodiment, so that the overall operability and simplicity of the vacuum cleaner are improved, and fewer dust collection accessories are used. Capable of meeting the vacuuming needs of almost any area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com