Sinning machine with high product quality

A product quality and spinning frame technology, applied in the textile field, can solve problems such as uneven roving tension, affecting product quality, and damaging rollers, so as to improve production efficiency and product quality, prevent yarn breakage, and reduce end-break rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

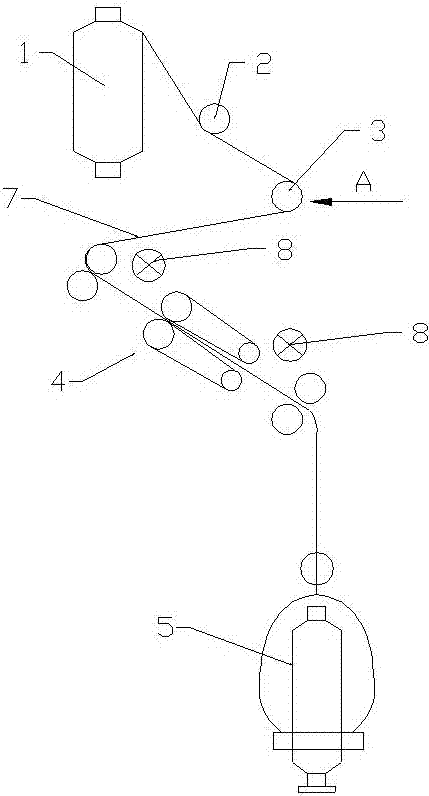

[0025] See Figure 1-3 The present invention relates to a spinning frame with high product quality. It includes a roving bobbin 1, a supporting rod 3, a roller 4 and a spindle 5. The yarn 7 passes through the roving bobbin 1, a supporting rod 3 and a roller 4 in turn, and finally on the spindle 5. Finish spinning.

[0026] A pressure tube 2 is arranged between the roving drum 1 and the support rod 3, and under the action of the pressure tube 2, the surface of the yarn 7 is straight and the tension is uniform.

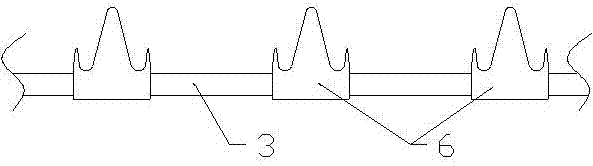

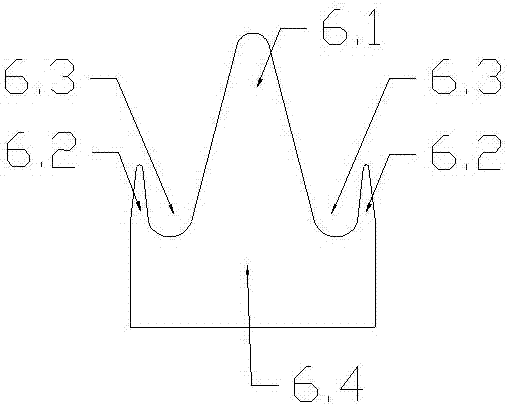

[0027] The support rod 3 plays a guiding role, and a slitter 6 is sleeved on the support rod 3, the slitter 6 includes a sleeve 6.4, the sleeve 6.4 is sleeved on the support rod 3, and the middle of the sleeve 6.4 A first protrusion 6.1 is provided. The two sides of the sleeve 6.4 are respectively provided with second protrusions 6.2. Two grooves 6.3 are formed between the first protrusion 6.1 and the second protrusion 6.2, and the roving from the roving tube 1 passes The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com