A Fixture for Shear Test of Riveted Parts of Composite Material Plate and Aluminum Alloy Plate

A technology of composite material plate and aluminum alloy plate, which is applied in the direction of analyzing materials, instruments, measuring devices, etc., can solve the problems such as the inability to test the shear strength of rivets, and achieve the effect of convenient and efficient shear resistance, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

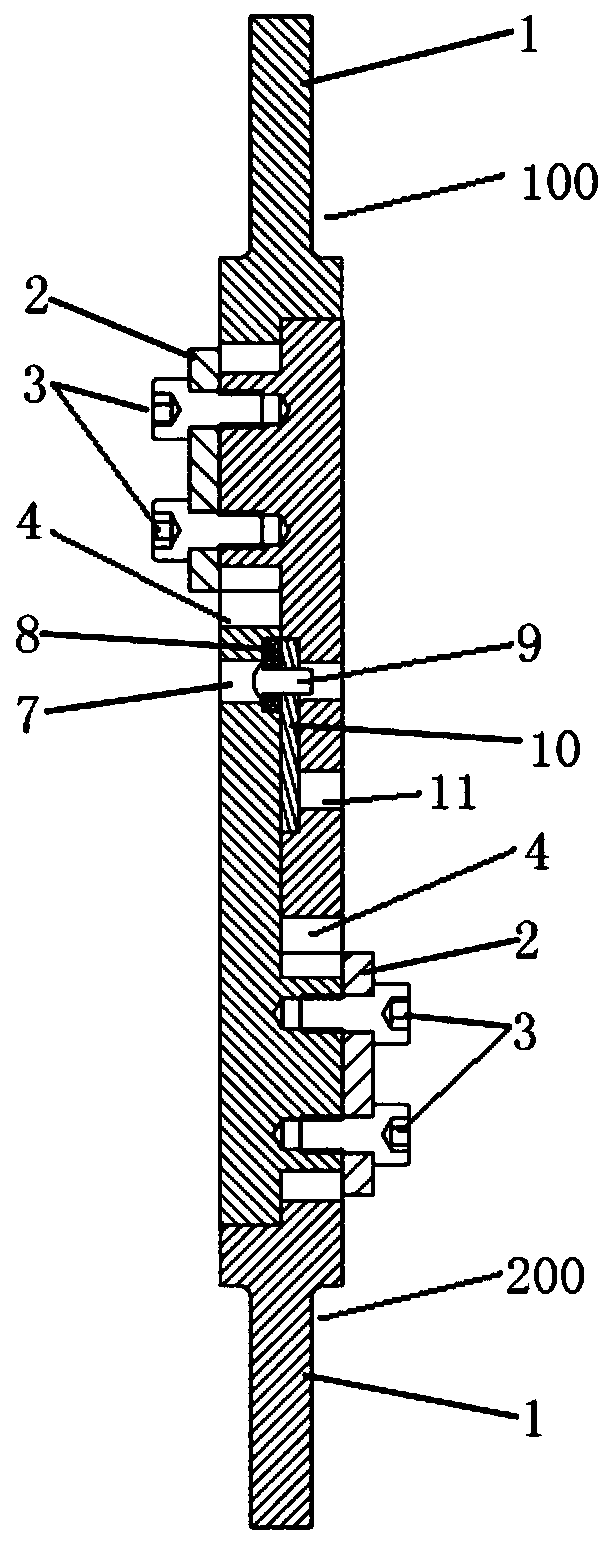

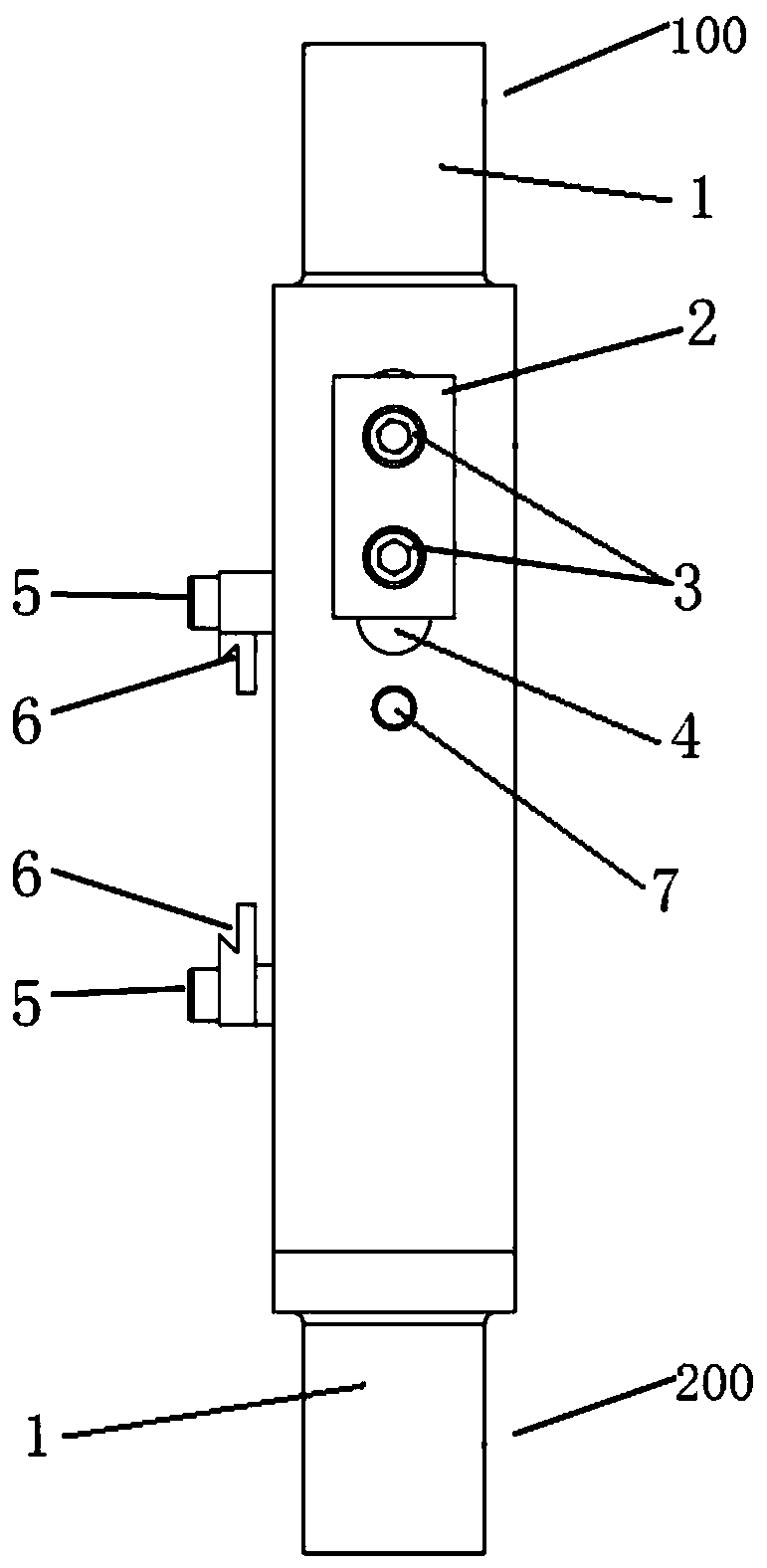

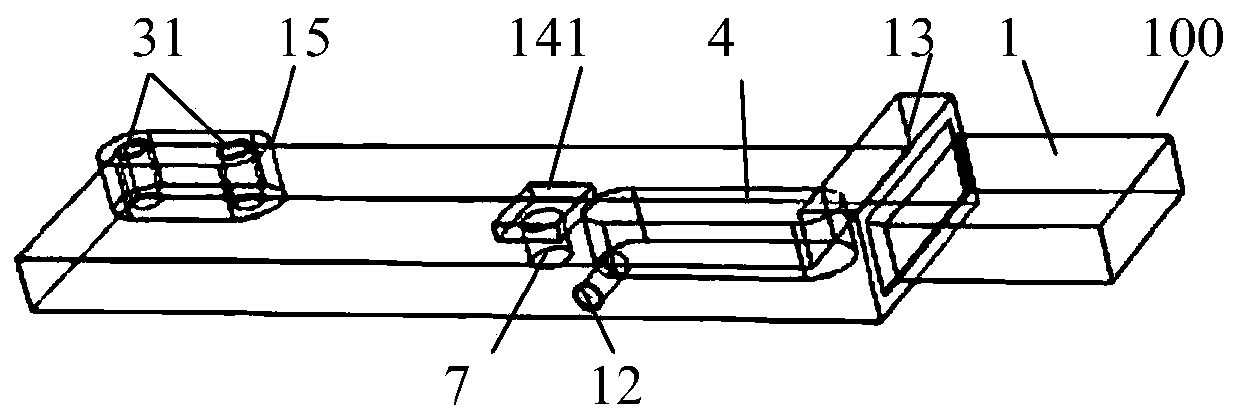

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

[0026] The present invention proposes a fixture for shear test of riveted parts of composite material plate and aluminum alloy plate, including a first splint 100, a second splint 200, two fastening plates 2 and two extensometer fixed knife-edge blocks 6 and related connectors.

[0027] The structures of the first clamping plate 100 and the second clamping plate 200 are basically the same, and the structure of the same part is to include a clamping section 1, a positioning step 13 and a sample clamping plate, and the sample clamping plate is from one end of the positioning step 13 to the other. One end is sequentially provided with a keyway 4, a sample placement groove and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com