Adhesive composition for polarizing film, adhesive layer for polarizing film, polarizing film with adhesive layer, and image display device

A technology of adhesive layer and polarizing film, which is applied in the direction of film/sheet adhesive, non-polymer adhesive additives, adhesive additives, etc., can solve the problem of not being able to fundamentally prevent static electricity generation, white unevenness, etc. , bad conditions and other problems, achieve excellent anti-static function and durability, suppress white unevenness, and meet the effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

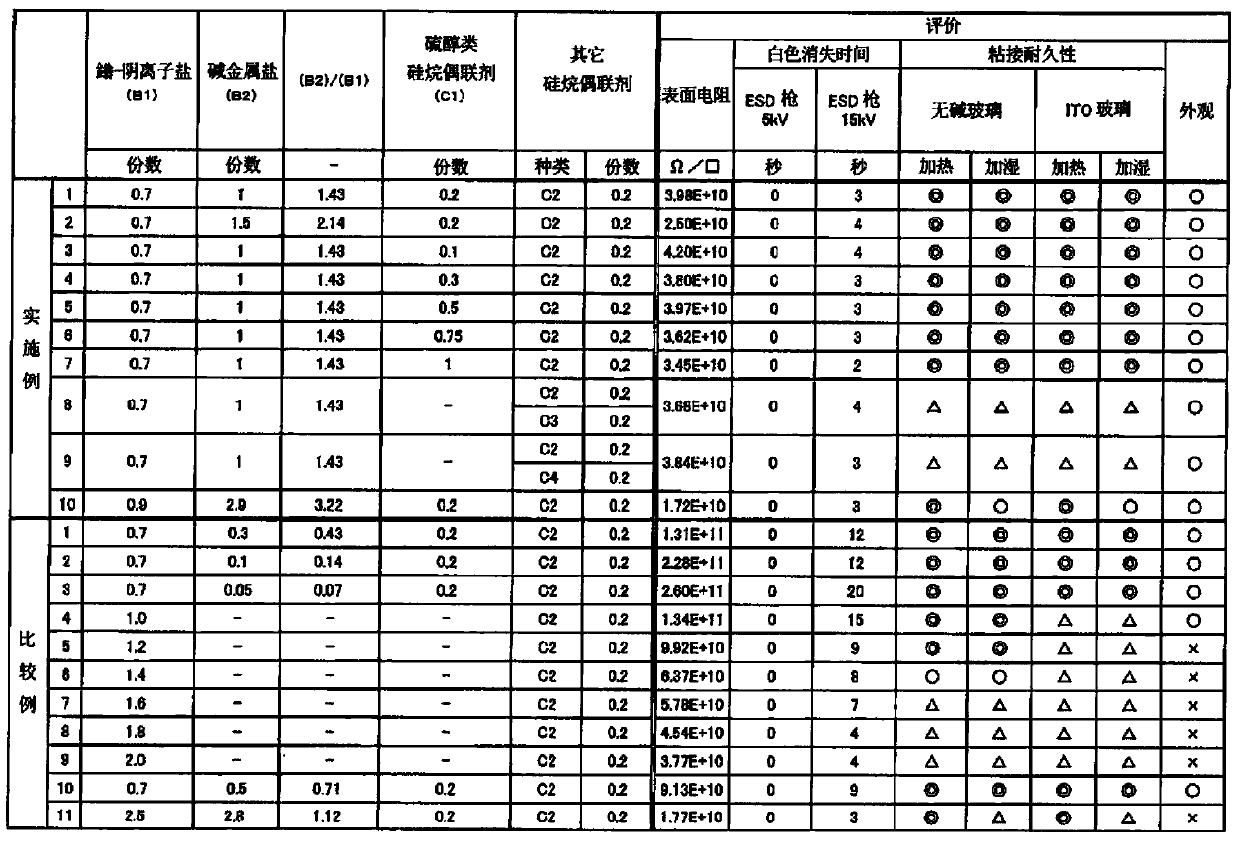

Examples

manufacture example 1

[0158] Production Example 1 (Preparation of Acrylic Polymer (A-1))

[0159] A monomer mixture containing 99 parts of butyl acrylate and 1 part of 4-hydroxybutyl acrylate was charged into a four-necked flask equipped with a stirring blade, a thermometer, a nitrogen introduction tube, and a condenser. Furthermore, 0.1 part of 2,2'-azobisisobutyronitrile as a polymerization initiator was added with ethyl acetate to 100 parts of the above-mentioned monomer mixture (solid content), and nitrogen gas was introduced while slowly stirring. After substitution, the liquid temperature in the flask was maintained at around 60° C., and a polymerization reaction was performed for 7 hours. Then, ethyl acetate was added to the obtained reaction liquid, and the solid content concentration was adjusted to 30%, and the solution of the acrylic polymer (A-1) whose weight average molecular weight was 1.4 million was prepared.

[0160] The weight average molecular weight of the obtained (meth)acryli...

manufacture example 2

[0172] Production example 2 (production of thin polarizing film)

[0173] In order to produce a thin polarizing layer, first, a laminate with a 9 μm thick PVA layer formed on an amorphous PET substrate was assisted in stretching in an atmosphere at a stretching temperature of 130°C to form a stretched laminate, and then , by dyeing the stretched laminated body to make a colored laminated body, and then stretching the colored laminated body in boric acid water at a stretching temperature of 65 ° C, so that the total stretching ratio is 5.94 times, and a non-woven fabric is made. An optical film laminate including a 4 μm thick PVA layer integrally stretched from a crystalline PET substrate. Through such two-step stretching, the PVA molecules formed on the PVA layer of the amorphous PET substrate are highly oriented, and an optical film laminate including a PVA layer with a thickness of 4 μm can be produced. A highly functional polarizing layer in which iodine adsorbed for dyein...

Embodiment 1

[0175] (Preparation of Adhesive Composition)

[0176] With respect to 100 parts of solid content of the acrylic polymer (A-1) solution obtained in Production Example 1, mix as - Ethylmethylpyrrolidine of the anionic salt (B1) -0.7 parts of bis(trifluoromethanesulfonyl)imide salt (manufactured by Tokyo Chemical Industry Co., Ltd.), lithium bis(trifluoromethanesulfonyl)imide (manufactured by Mitsubishi Materials Electronic Chemicals) as alkali metal salt (B2) 1 Parts, further blending 0.095 parts of trimethylolpropane xylylene diisocyanate (trade name: Takenate D110N, manufactured by Mitsui Chemicals Co., Ltd.) and dibenzoyl peroxide (trade name: NYPER BMT40SV, manufactured by NOF Corporation) 0.3 part, alkoxysilyl resin containing a methyl group and a mercapto group as a thiol-based silane coupling agent (C1) (trade name: X-41-1810, Shin-Etsu Chemical Co., Ltd. Co., Ltd.) 0.2 parts, 0.2 parts of an acetoacetyl group-containing silane coupling agent (trade name: A-100, manuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap