Microwave composite heating furnace

A combined heating and microwave technology, applied in microwave heating, electric furnace heating, lighting and heating equipment, etc., can solve the problems of increasing device cost and operating cost, increasing output devices, etc., to improve reaction efficiency and energy efficiency, and increase freedom degree, high heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

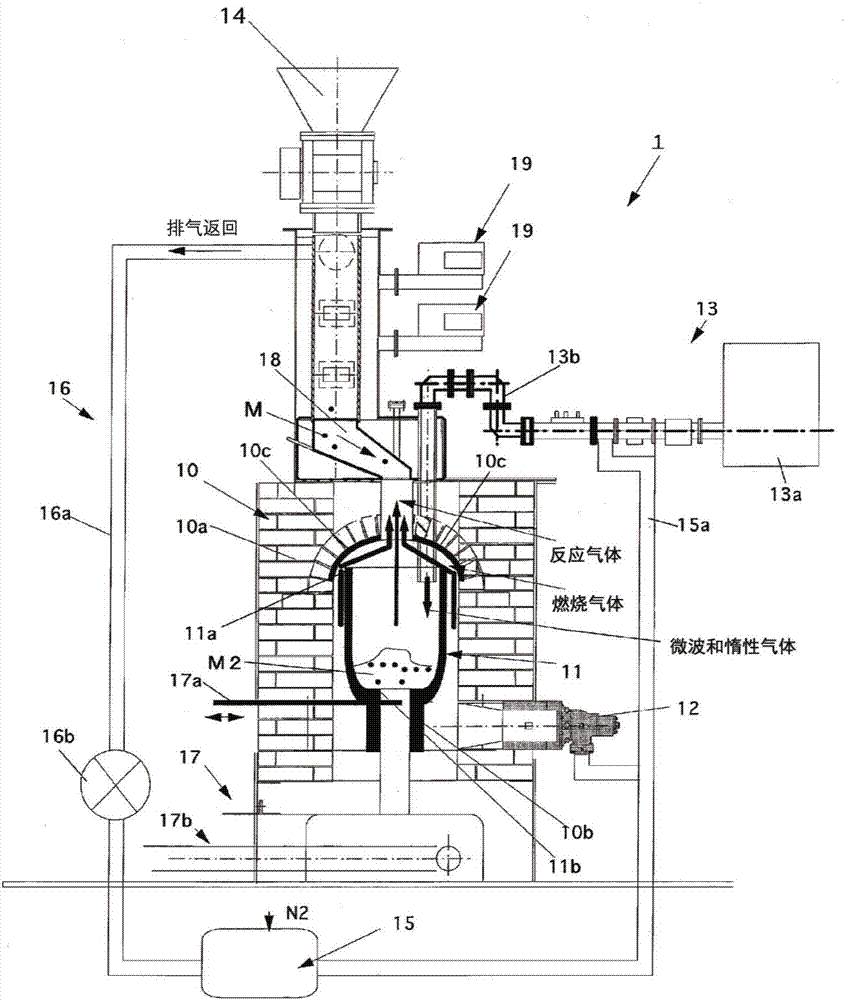

[0060] The first embodiment of the microwave composite heating furnace of the present invention will be described below with reference to the accompanying drawings.

[0061] The structure of microwave composite heating furnace

[0062] like figure 1 As shown, the microwave composite heating furnace 1 includes: a housing 10; a heating container 11, which is located inside the housing 10, stores a heated object therein, and heats the heated object; a heating unit 12 for heating The heating container 11 is heated externally; the microwave irradiation device 13; the heated object supply device 14 is used to supply the heated object into the heating container 11; the gas introduction unit 15 is used to introduce gas to adjust the temperature in the heating container 11 gas; a gas collecting unit 16 for collecting and treating processing gas generated when a heated object is heat-treated; and a control device not shown.

[0063] The housing 10 includes a refractory wall 10a forme...

Embodiment 2

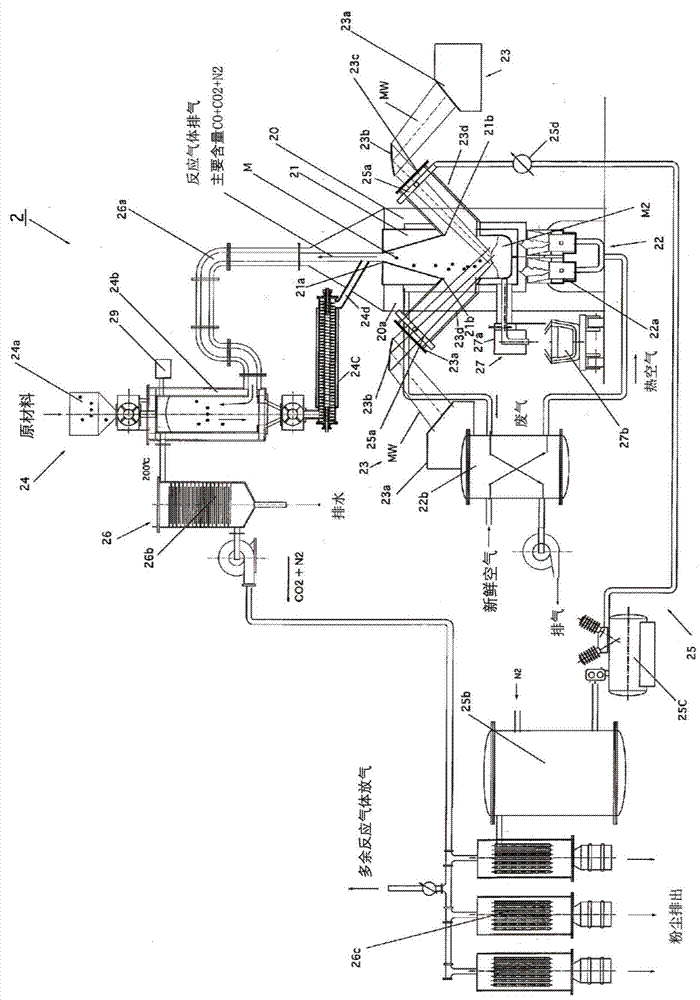

[0099] The second embodiment of the microwave composite heating furnace of the present invention will be described below with reference to the accompanying drawings.

[0100] The microwave composite heating furnace 2 comprises: a housing 20; a heating container 21, which is arranged in the housing 20, and stores and heats objects to be heated; a heating unit 22, which is used to externally heat the heating container 21; a microwave irradiation device 23; the heated object supply device 24 is used to supply the heated object into the heating container 21; the gas introduction unit 25 is used to introduce gas so as to adjust the gas in the heating container 21; the gas collection unit 26 is used to collect and processing gas generated when a heated object is heat-treated; and a control device not shown.

[0101]The housing 20 is made of a refractory wall 20a formed of insulating material such as refractory bricks, and stores the heating container 21 therein.

[0102] The heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com