Quantitative seed dropping mechanism

A technology of dropping and dropping seeds, which is applied in the direction of interval-type quantitative seeding machinery and parts of seeders, can solve the problems of difficulty in controlling the amount of seeding, poor reliability of seeding, and achieve convenient and efficient seeding. Uniform and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

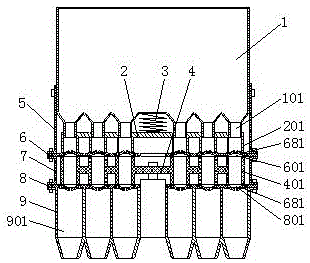

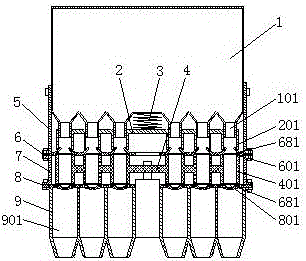

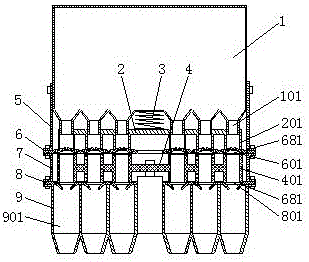

[0014] Now in conjunction with accompanying drawing, the present invention is described as follows.

[0015] Such as Figure 1-3 As shown, the quantitative seeding mechanism includes a seeding box 1, a guide sleeve seat 2, an upper seeding valve plate 6, a seeding valve block 4, a falling seeding valve plate 8, and a seeding guide seat 9. The bottom of the seeding box 1 is provided with There is a row of seed drop tubes 101 distributed at intervals, and the position at the entrance of the seed drop tube 101 in the seed drop box 1 is funnel-shaped. The guide sleeve seat 2 is integrated with the guide sleeve 201 which is matched with the seed drop tube 101 at the bottom of the seed drop box 1 one by one, and a low and tight return spring 4 is arranged between the guide sleeve seat 2 and the bottom of the seed drop box 1 . The upper seed valve plate 6 is provided with a first seed valve port 601 corresponding to each guide sleeve 201 end of the guide sleeve seat 2 one by one. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com