Convenient concrete stirring device

A mixing device and concrete technology, which is applied in the direction of cement mixing device, clay preparation device, coupling device, etc., can solve the problems of easy loosening, poor contact, easy generation of arc, etc., and achieve the effect of convenient power transmission connection and preventing exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

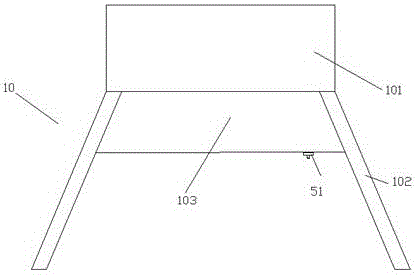

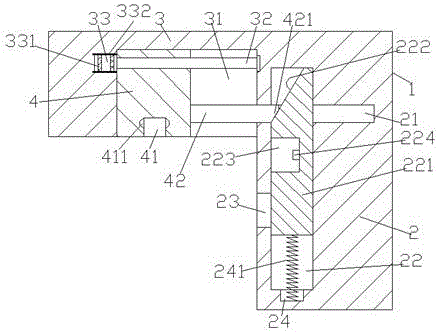

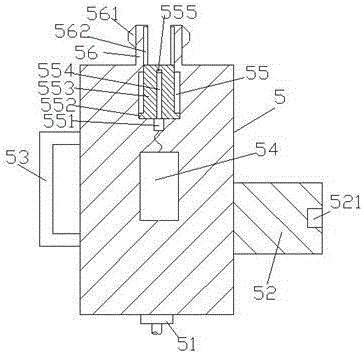

[0022] Such as Figure 1-Figure 6 As shown, a convenient concrete mixing device of the present invention includes a mixer frame 10 and a power transmission device. The mixer frame 10 includes a mixing drum 101 and a plurality of sets of legs 102, and each group of legs 102 is located between the mixing drums The lower part of 101 is provided with a driving device 103. The power transmission device includes a power transmission station 1 and a power transmission arm 5 composed of an insertion end 3 and a mounting base 2. The insertion end 3 is fixedly arranged at the upper left side of the installation base 2. , the bottom end surface of the insertion end 3 is provided with a slide-in groove 31, and the slide-in groove 31 is provided with a first screw rod 32 elongated left and right, and the left end of the first screw rod 32 is connected to the The first motor 33 is connected, and the right side end of the first screw rod 32 is turned and mated with the right inner end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com