A tape label paper feeding device that can automatically adjust the position and size

A technology of automatic adjustment and feeding device, used in labels, packaging, labeling machines, etc., can solve the problems of wasting time and different sizes of tapes, and achieve the effect of improving production efficiency, fast and convenient replacement, and reducing enterprise costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

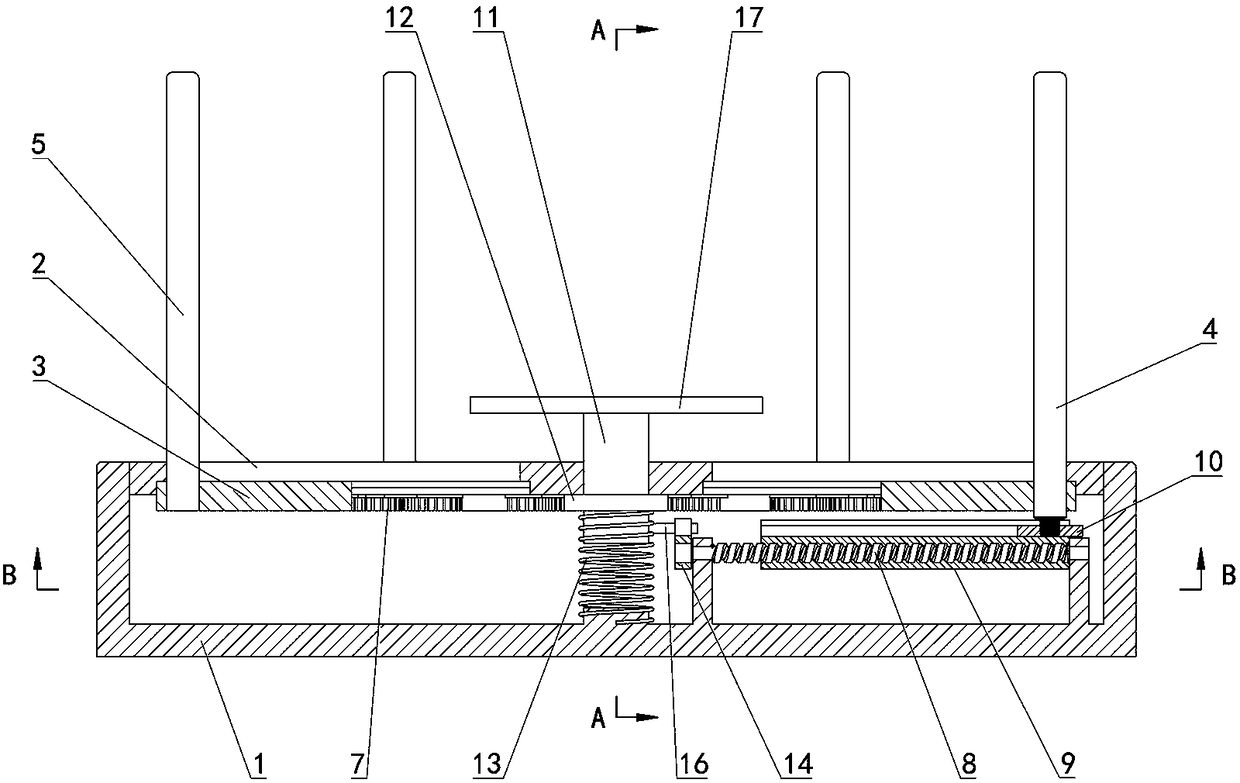

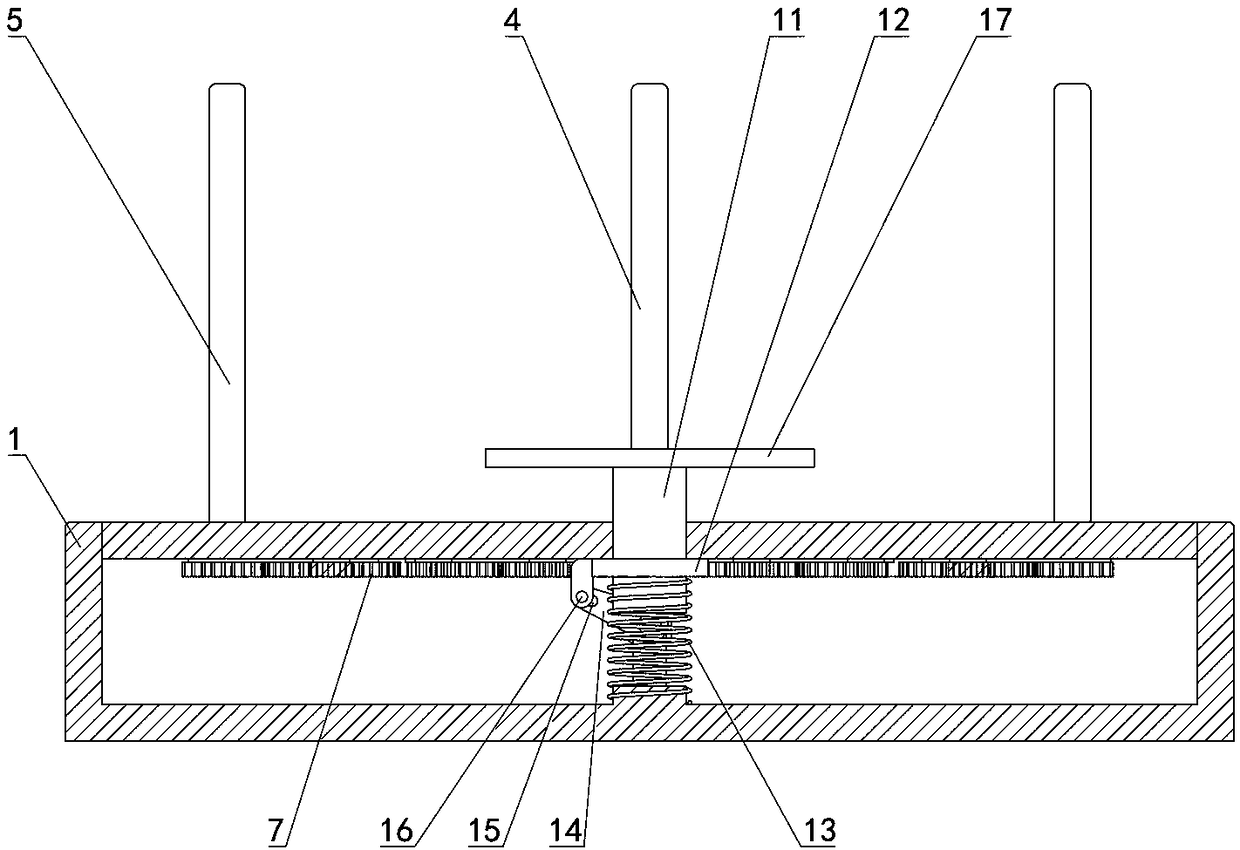

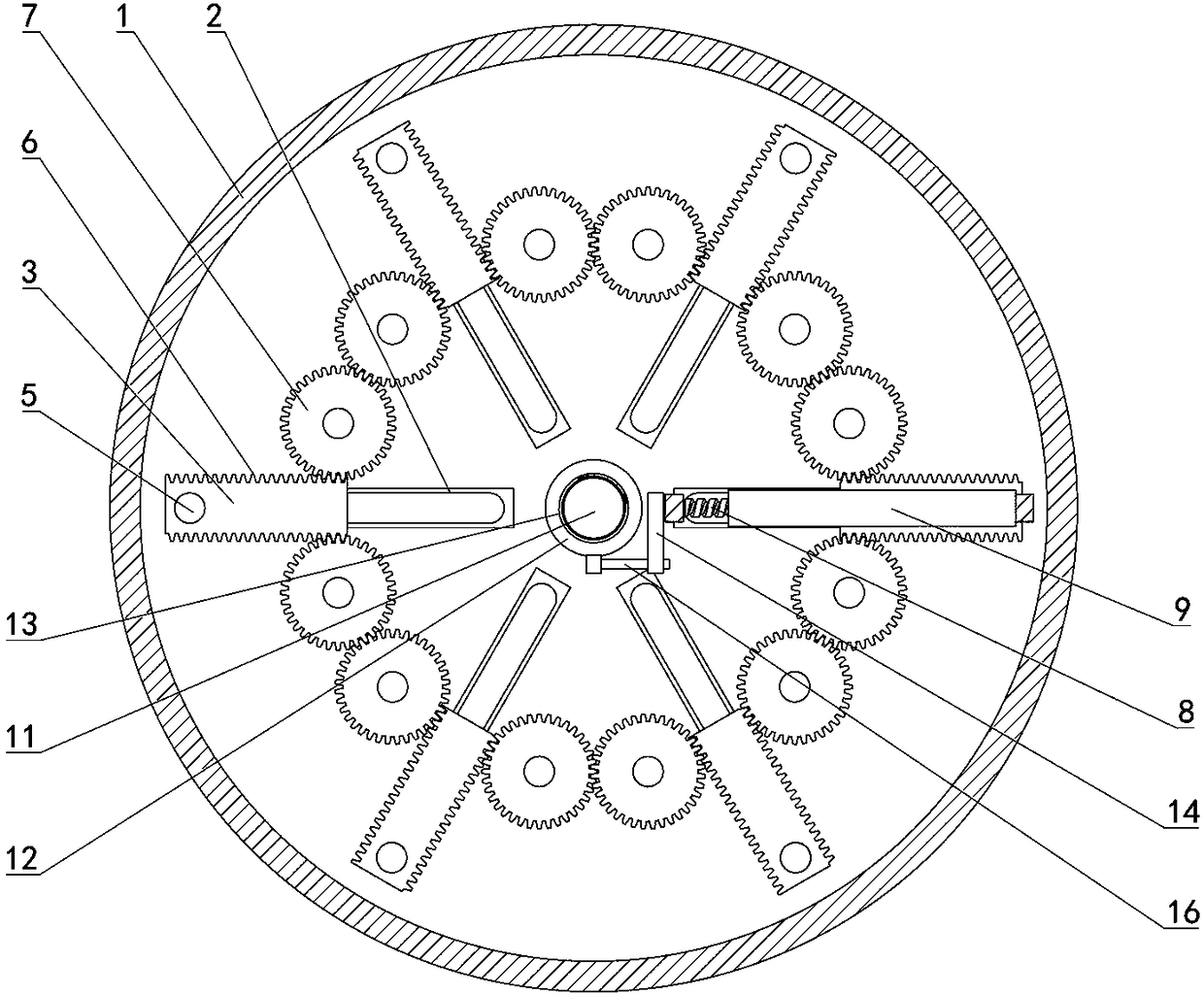

[0014] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] Depend on Figure 1 to Figure 4 Given, the present invention comprises a chassis 1 with a cavity, the upper end surface of the chassis 1 is provided with a plurality of centripetal chute 2 that runs through the upper part of the chassis 1 and is circumferentially distributed, and the centripetal chute 2 is equipped with a 2 Sliders 3 that slide inside, one of the sliders 3 corresponding to the centripetal chute 2 is equipped with a rotatable adjustment bar 4 that runs through the slider 3 vertically, and the other sliders 3 are equipped with vertically arranged stop rod 5;

[0016] Described slide block 3 is equipped with two tooth racks 6 that are respectively placed on both sides of the centripetal chute 2 and consistent with the length direction of the centripetal chute 2. The gear 7 meshed with the bar 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com