Negative ring introducing device for super-large-section quasi-rectangular pipe jacking construction steel structure

A super-large cross-section and steel structure technology, applied in mining equipment, shaft equipment, shaft lining, etc., can solve problems such as high risk of hoisting, high cost of construction, and difficulty in handling, so as to achieve easy turnover hoisting, reduce cost and use cost , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

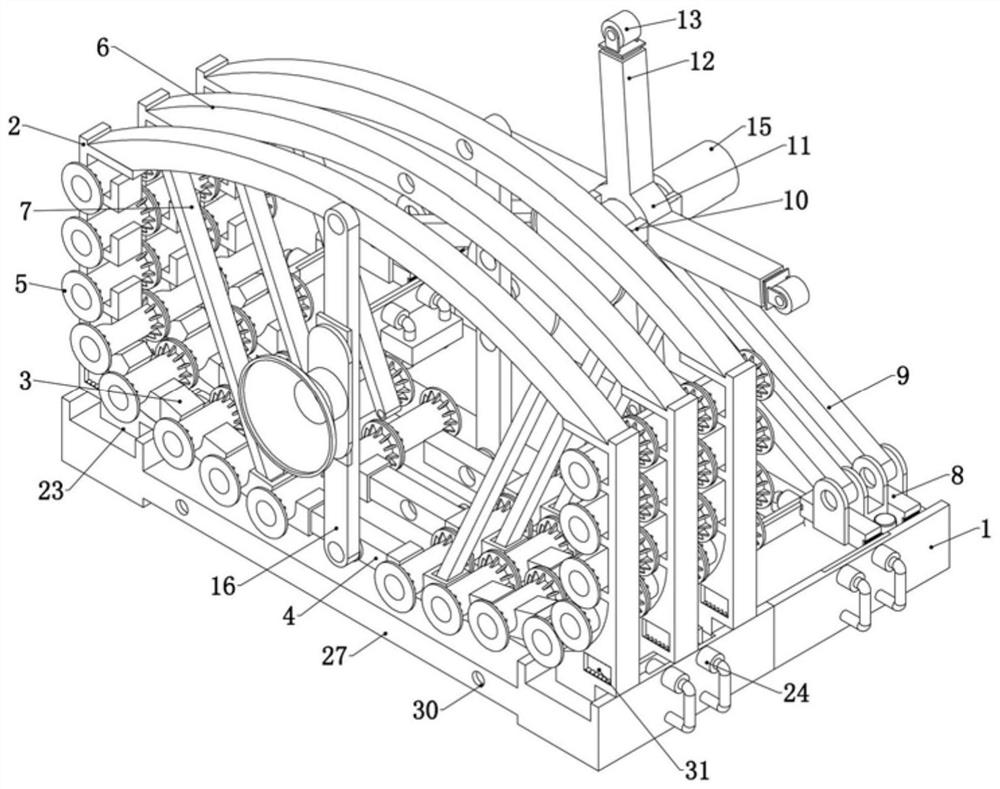

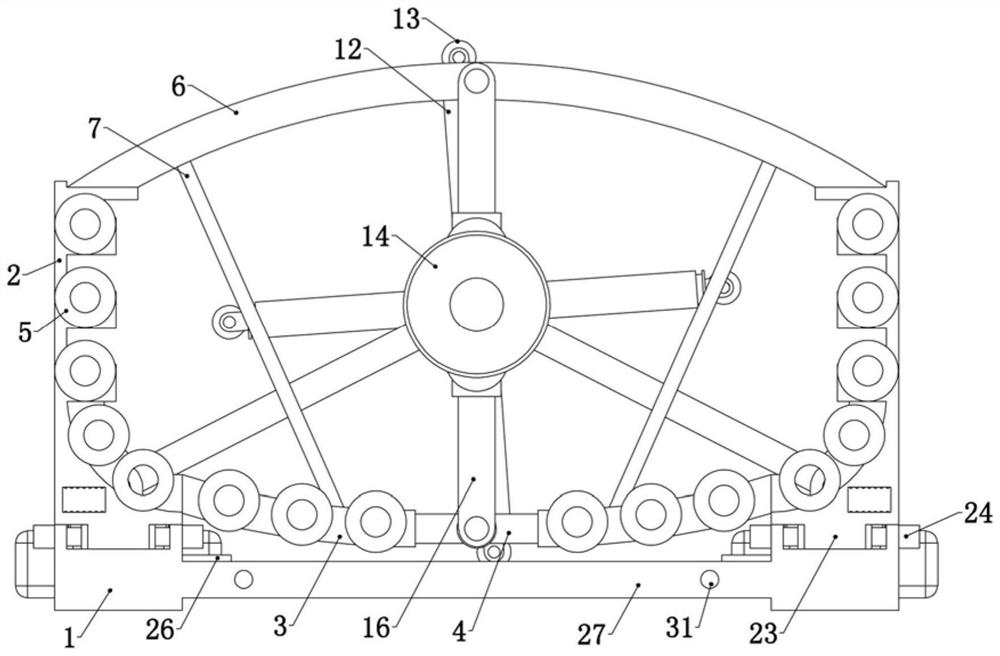

[0051] Embodiment 1, the present invention is a device for citing the negative ring of a super-large-section rectangular pipe jacking construction steel structure, including a prefabricated pipe joint and a top iron, and one end of the top iron is connected to a jacking oil cylinder fixedly connected in the originating shaft , the prefabricated pipe joint is a concrete pipe joint that needs to be jacked into the formation, the jacking iron is placed between the jacking cylinder and the prefabricated pipe joint, and the other end of the jacking cylinder is fixedly connected to the inner wall of the launching shaft. The common technical setting of the pipe method is characterized in that it includes multiple sets of single-ring steel structures that are detachably connected to each other. Multiple sets of single-ring steel structures are placed between the top iron and the prefabricated pipe joints. The pipe joints in the layer are not the negative ring pipe joints. At this time,...

Embodiment 2

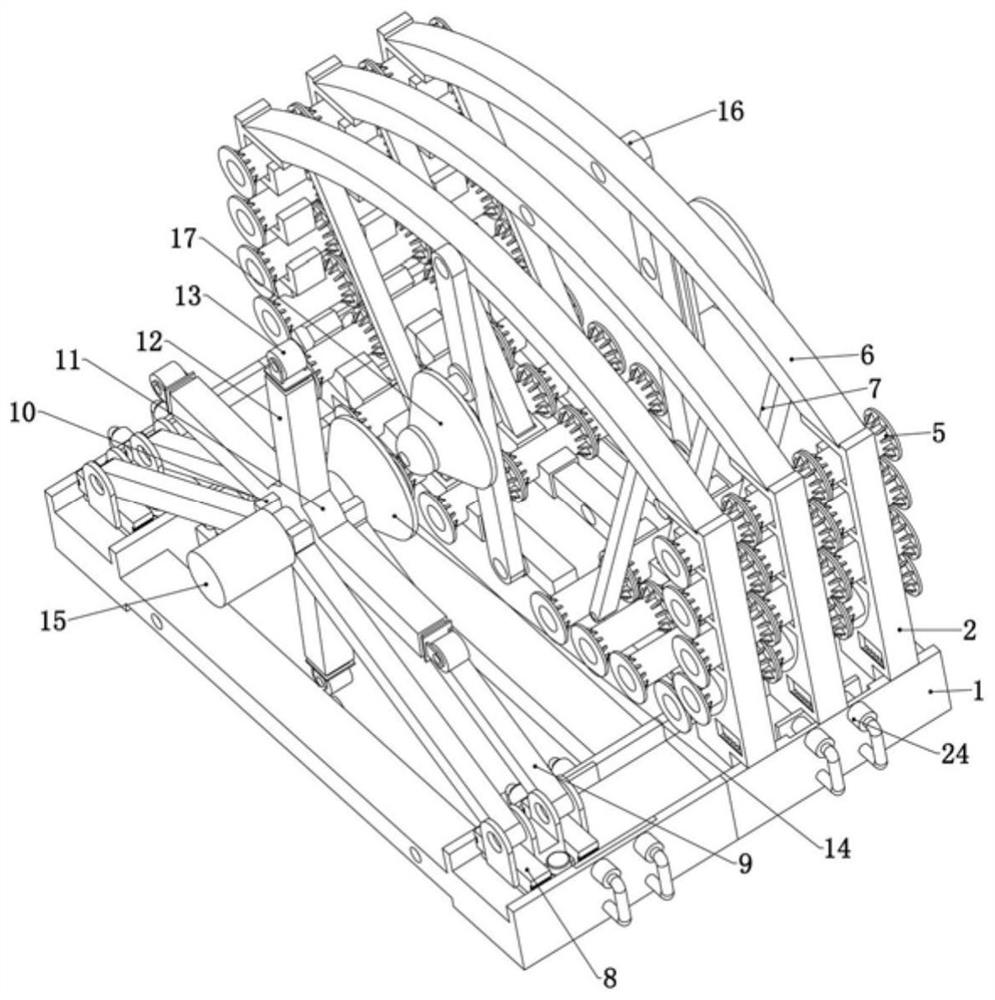

[0066] Embodiment two, on the basis of embodiment one, refer to figure 1 , image 3 The two described slide rails 1 are all slidably connected with a positioning trolley 8, and the two described positioning trolleys 8 are detachably connected with a positioning coupling beam 9, and the other ends of the two positioning coupling beams 9 are fixedly connected. There is the same positioning base 10, the positioning base 10 is rotatably connected with a cylindrical positioning bin 11, the positioning trolley 8 can move along the slide rail 1, and the positioning bin is driven by the positioning connecting beam 9 and the positioning base 10 11 move synchronously, the positioning bin 11 is a hollow cylindrical bin body, the positioning base 10 is a semi-circular base, the positioning bin 11 and the positioning base 10 are connected by a large bearing, and the positioning bin 11 side wall There are four positioning oil cylinders 12 uniformly fixed and connected, and the other ends o...

Embodiment 3

[0070] Embodiment 3, on the basis of Embodiment 2, one end of the positioning chamber 11 is fixedly connected with a guide cylinder 18, the guide cylinder 18 is a hollow cylindrical structure, one end is connected with the positioning chamber 11, and the other end is narrow with the guide cone shell 14 The mouth is connected, and the other end of the guide cylinder 18 is fixedly connected with the guide cone shell 14;

[0071] One end of the guide cone 17 is fixedly connected with a guide column 19, the outer diameter of the guide column 19 is the same as the inner diameter of the guide cylinder 18, and one end of the guide column 19 is provided with a fillet, when the guide cone 17 enters the guide cone When inside the shell 14, the guide column 19 can first guide the inner side wall of the cone shell 14 to contact. The axis coincides with the same axis, when the support frame and the prefabricated pipe joint contact, the guide column 19 enters the guide cylinder 18, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com