A Test Method of H-bridge Output Waveform Dead Time

A technology of dead time and output waveform, applied in the direction of cathode ray oscilloscope, etc., can solve the problems of poor definition, complicated measurement method, large error, etc., and achieve the effect of easy observation and operation, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

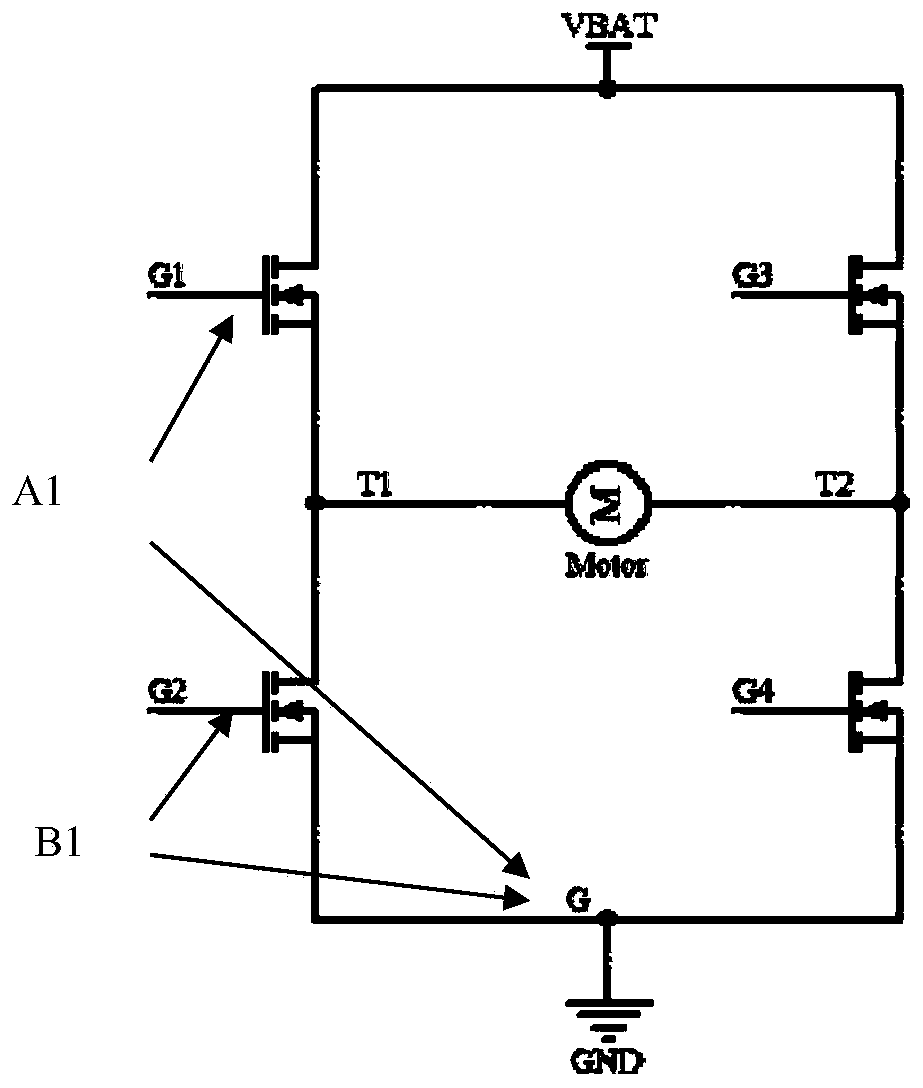

[0024] Figure 5 It is a schematic diagram of the method for directly measuring the dead time of the output terminal in the present invention.

[0025] See Figure 5 , the invention provides a kind of testing method of H-bridge output waveform dead time, wherein, comprise the steps:

[0026] 1. First select two suitable power resistors R1, R2;

[0027] 2. Then connect the power resistors R1 and R2 in parallel to one arm of the H-bridge. Here we take the parallel connection on Q3 and Q4 as an example to illustrate;

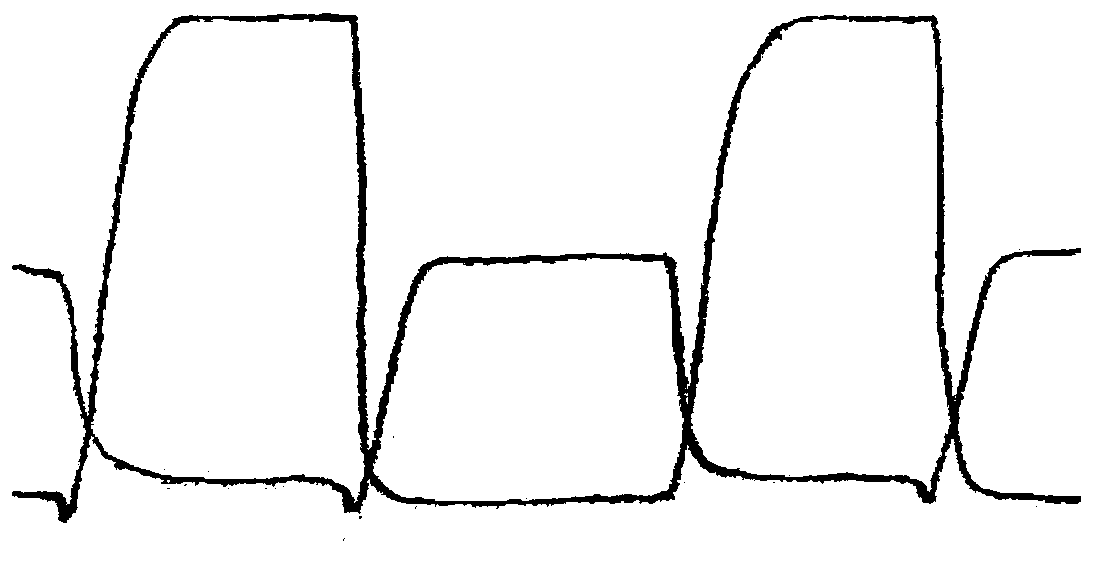

[0028] 3. After connecting the circuit, use an oscilloscope test lead A to measure Figure 5 For the waveform between T2 and G in the circuit, see Figure 6 A schematic diagram of the waveform of a motor control circuit measured by this method, Figure 6 The circled part is the dead time of the output waveform;

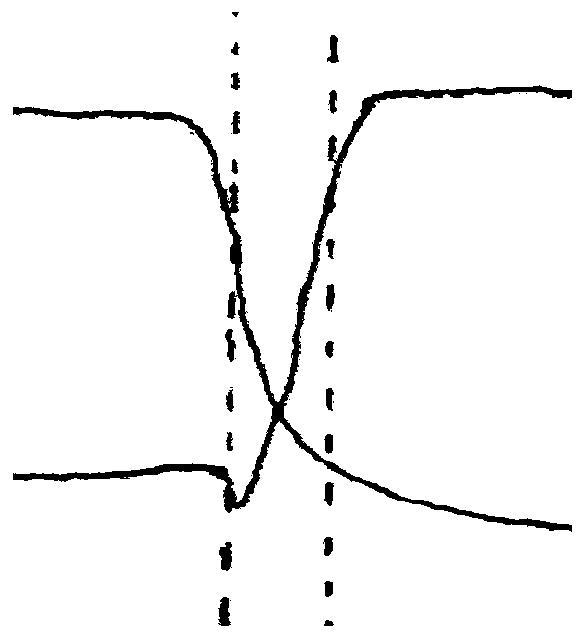

[0029] 4. Zoom in on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com