Wire wear performance test system and method

A wear performance and testing system technology, applied in the direction of testing wear resistance, measuring device, strength characteristics, etc., can solve the problem of lack of effective methods for wear testing of large span and ultra-high strength aluminum alloy wires, and achieve the effect of accurate wear test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

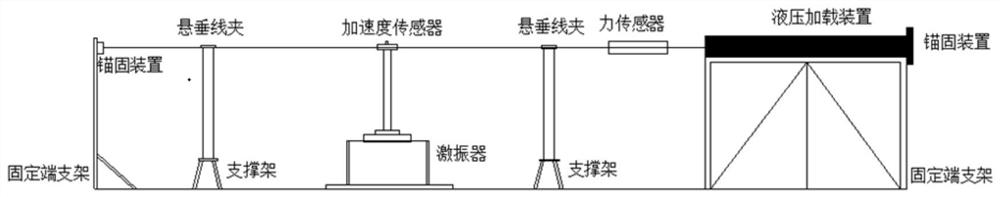

[0065] This embodiment provides a wire wear performance testing system, the system structure diagram is as follows figure 1 shown.

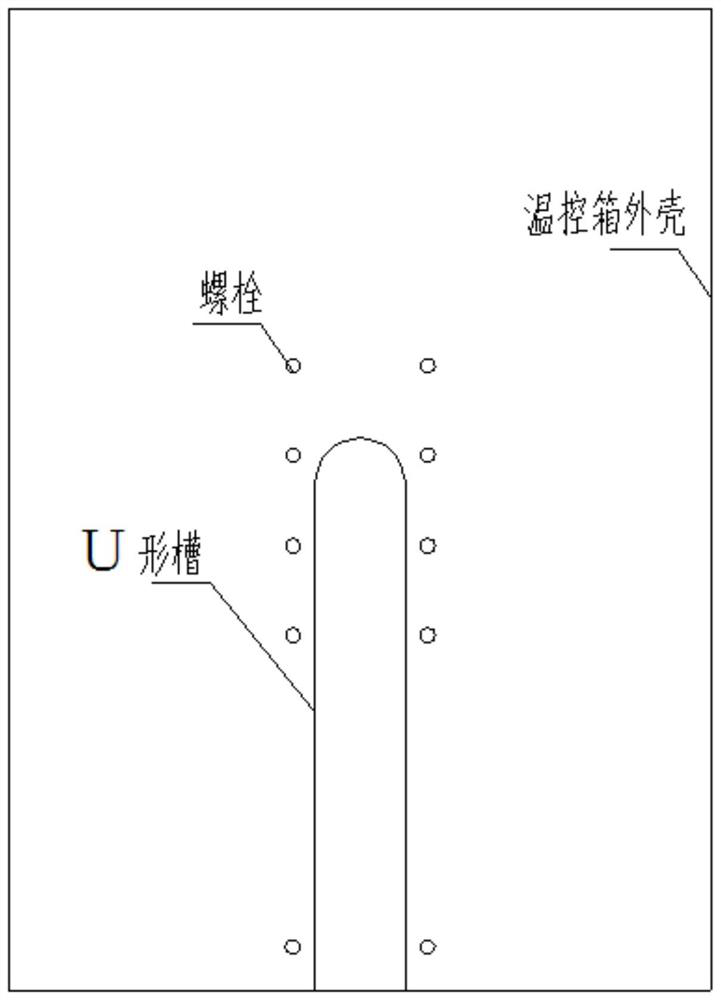

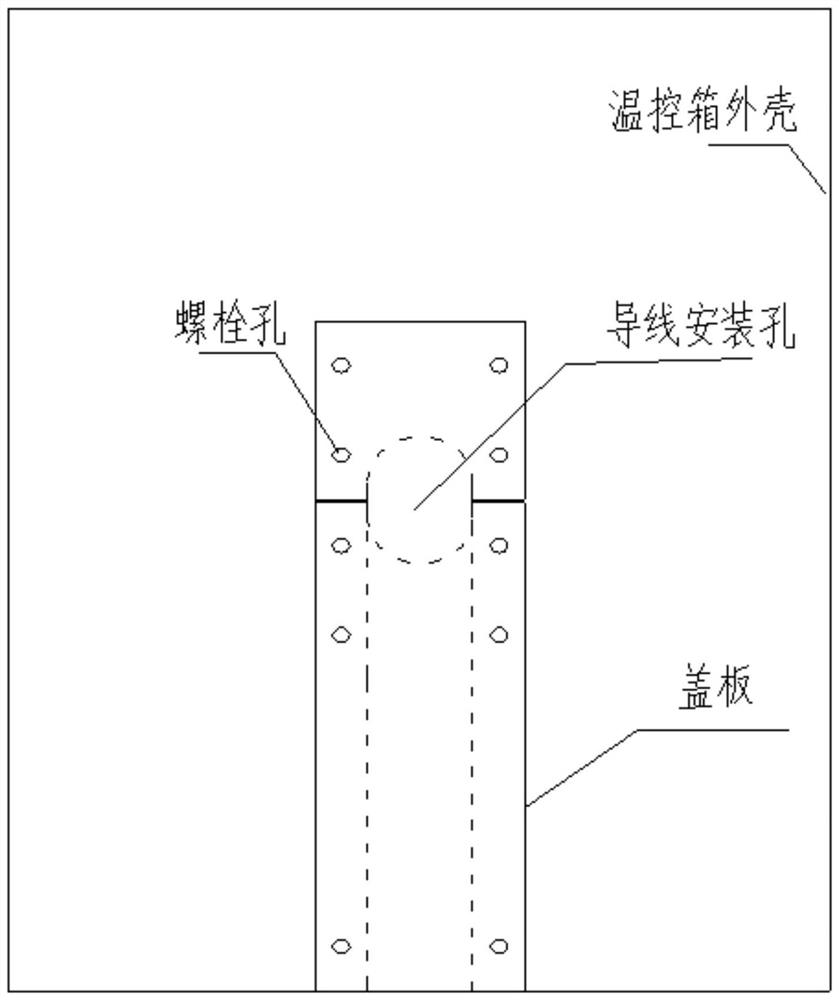

[0066]The long-span ultra-high-strength aluminum alloy wire wear test system consists of six parts: tensioning system, support and anchor system, excitation system, temperature control system, data acquisition system and intermediate ultra-high-strength aluminum alloy wire. The tensioning system applies tension to the ultra-high-strength aluminum alloy wire through the hydraulic loading device, and the force sensor measures the tension value of the test wire; the anchoring system consists of a bracket and an anchoring end, which is used to anchor the wire after the tension is applied; vibration The system consists of an electromagnetic vibrating table and a head and is connected to an ultra-high-strength aluminum alloy wire through a chuck. The vibrating table is a hydraulic vibrating table and is equipped with a vibration closed-loop control sys...

Embodiment 2

[0071] This embodiment provides an installation method of a wire wear performance testing system.

[0072] The installation steps of the large-span ultra-high-strength aluminum alloy wire wear test system can be divided into 9 installation steps. The first step is to take the ultra-high-strength aluminum alloy wire sample. The wire sample should choose a line segment without looseness and damage. During the cutting and preparation process, care should be taken not to damage the sample (the length of the wire should be cut to 39m and the length of the anchor head should not be included. ); Before the test piece is cut from the spool, at least two strong clamps shall be provided at each end of the test piece to prevent movement between the wire layers. The second step is to make the anchor head. The two ends of the wire are put into the anchor head and the rear end is bent into a lantern net shape, and then the anchor heads at both ends are hung on the iron frame and cast with ...

Embodiment 3

[0074] This embodiment provides a testing method for wire wear performance.

[0075] In the wear test of the large-span ultra-high-strength aluminum alloy conductor, first support the end of the conductor (the conductor length is 35m) with a suspension wire and fix the conductor end with an anchor; then use the loading system on the right side of the conductor to the other end of the conductor After applying 25% RTS tension to the wire and fixing the anchor at the end. Vibration debugging of the entire system is required before the wear test of the ultra-high-strength aluminum alloy wire. First, debug the temperature of the temperature control box. First, preheat the temperature control box to see if the insulation system can maintain a constant temperature; then use the excitation device to excite the test wire at an appropriate frequency to see if the wire Whether the vibration intensity can be kept stable. After the debugging of the whole system is completed, the wear tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com