Low-frequency composite sound absorption device

A composite sound-absorbing and low-frequency technology, applied in the direction of sound-generating equipment, instruments, etc., can solve the problem of narrow sound-absorbing frequency band, and achieve the effect of widening sound-absorbing bandwidth and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

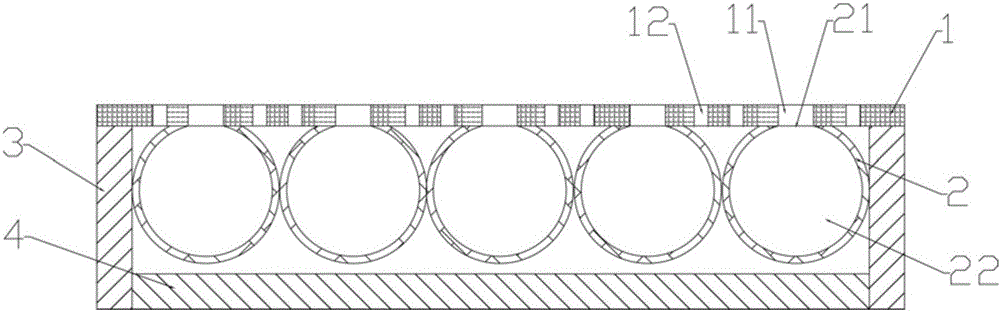

[0026] Such as figure 1 As shown, a low-frequency composite sound-absorbing device provided by an embodiment of the present invention includes a sound-absorbing board 1 and a Helmholtz resonator 2. The sound-absorbing board 1 is provided with a plurality of sound-absorbing holes 12 and unit holes 11. The holes 11 are circular holes or rectangular holes. The number of Helmholtz resonators 2 is equal to the number of unit holes 11, and the plurality of Helmholtz resonators 2 are connected to the plurality of unit holes 11 in a one-to-one correspondence. The Helmholtz resonator 2 includes a cavity 22 and an opening 21 communicating with the cavity. In this embodiment, the cavity 22 is spherical. In addition, the shape of the cavity 22 is not limited, and there are multiple Helmholtz The openings 21 of the resonator 2 all face the front side of the sound absorbing panel 1. When in use, install the low-frequency composite sound-absorbing device on the walls, ceilings, doors and wind...

Embodiment 2

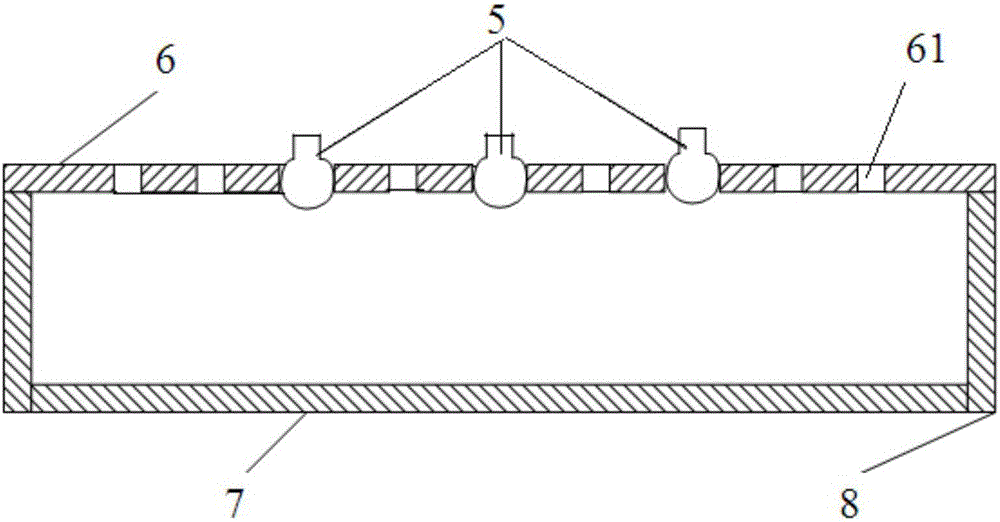

[0034] Such as figure 2 As shown, the structure of the low-frequency composite sound absorbing device provided in this embodiment is similar to that of the low-frequency composite sound absorbing device provided in the embodiment, and the same parts will not be repeated. The difference between the two is: the shape of the unit hole in this embodiment is The shape of the outer contour of the Helmholtz resonator 5 is matched, and a plurality of Helmholtz resonators 5 are embedded in a plurality of unit holes one-to-one, and the opening is located on the side of the front of the sound-absorbing panel. In other words, the end of the Helmholtz resonator 5 with an opening is located on the side of the front of the sound-absorbing board 6, the bottom of the Helmholtz resonator 5 is located on the side of the back of the sound-absorbing board 6, and the opening is Extends outward to form an elongated neck. In addition, the sound-absorbing plate 6 of this embodiment is a perforated pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com