Uniform-feeding pigsty structure

A pigpen, uniform technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of large gap between pigs, lack of pig food, and waste of feed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for limiting the present invention.

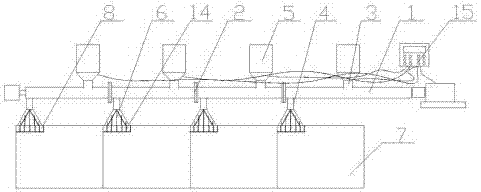

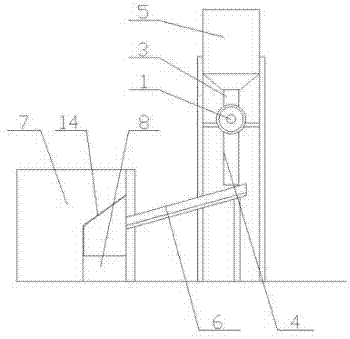

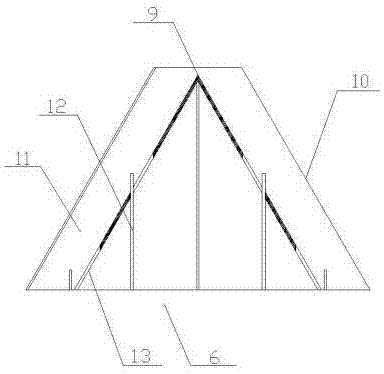

[0015] Embodiment of the present invention: a pigsty structure with uniform feeding, as attached Figure 1-3 As shown, the pigsty body 7 is included, and the top of the pigsty body 7 is provided with a screw feeder 1, and the screw feeder 1 is divided into multiple sections by the grid baffle 2, and each section is provided with a feeding port 3 and a feeding port 4. The feeding port 3 is provided with a storage tank 5, the head end of the discharge port 4 is connected with the head end of the triangular distribution plate 6, and the tail of the triangular distribution plate 6 is set on the wall of the pigsty body 7 close to the trough 8 Above, below its tail is the trough 8; the triangular material distribution plate 6 is provided with a herringbone material baffle 9, and a sliding chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com