Automatic feeding ultrasonic honing machine

A honing machine and ultrasonic technology, applied in the field of automatic feeding ultrasonic honing machine, can solve the problems of low honing efficiency, low degree of automation, and large changes in the expansion pressure of oil stones, and achieve the effect of improving honing quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

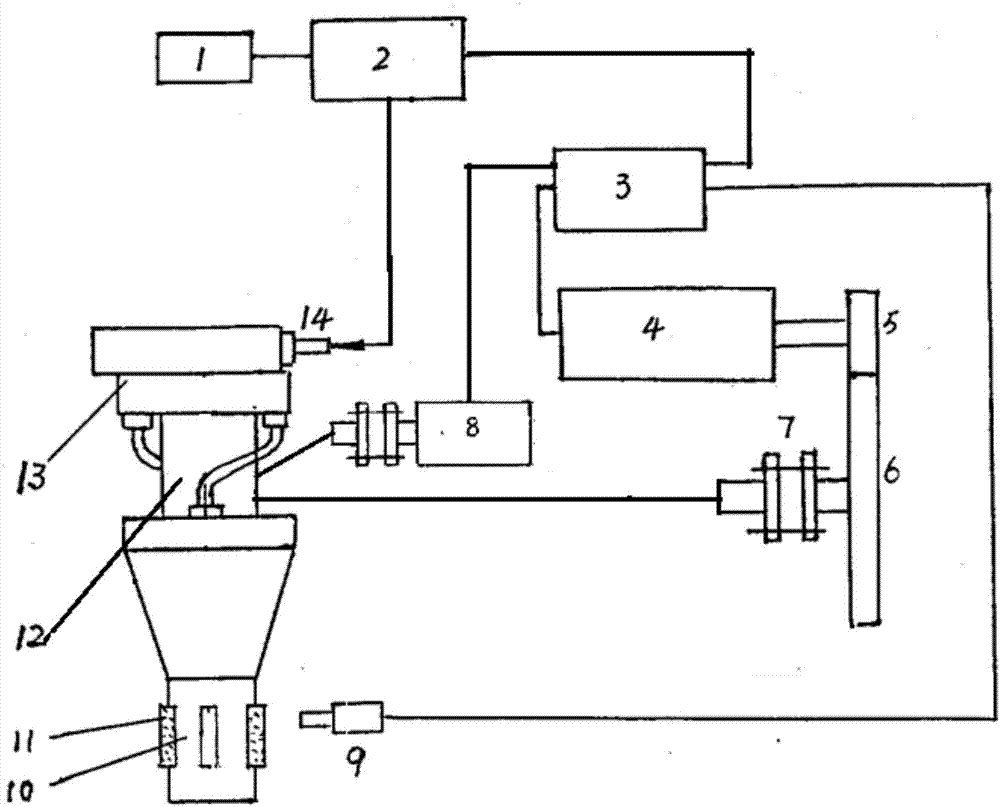

[0023] An automatic feeding ultrasonic honing machine, comprising a transducer 13, a rotating shaft 12, a honing head 10 arranged below the rotating shaft 12, and a honing stone 1 arranged on the honing head 10, the ultrasonic honing machine includes a A detection unit, a PLC controller 3 connected with the detection unit for controlling the rotating speed of the rotating shaft 12, a power unit connected with the PLC controller 3 for controlling the rotation of the rotating shaft 12, and a power unit connected with the PLC controller 3 for controlling the feeding Material unit, when the detection unit detects that the degree of expansion of the oil stone 1 meets the requirements, the PLC controller 3 controls the rotation of the rotating shaft 12, and adjusts its speed, and at the same time controls the feeding of the feeding unit.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap