Skew linear gear mechanism for constructing drive line teeth by means of planar Archimedes spiral

A technology of Archimedes spiral and gear mechanism, which is applied in the direction of gear transmission, elements with teeth, belt/chain/gear, etc., to achieve the effect of reducing spatial dimension and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

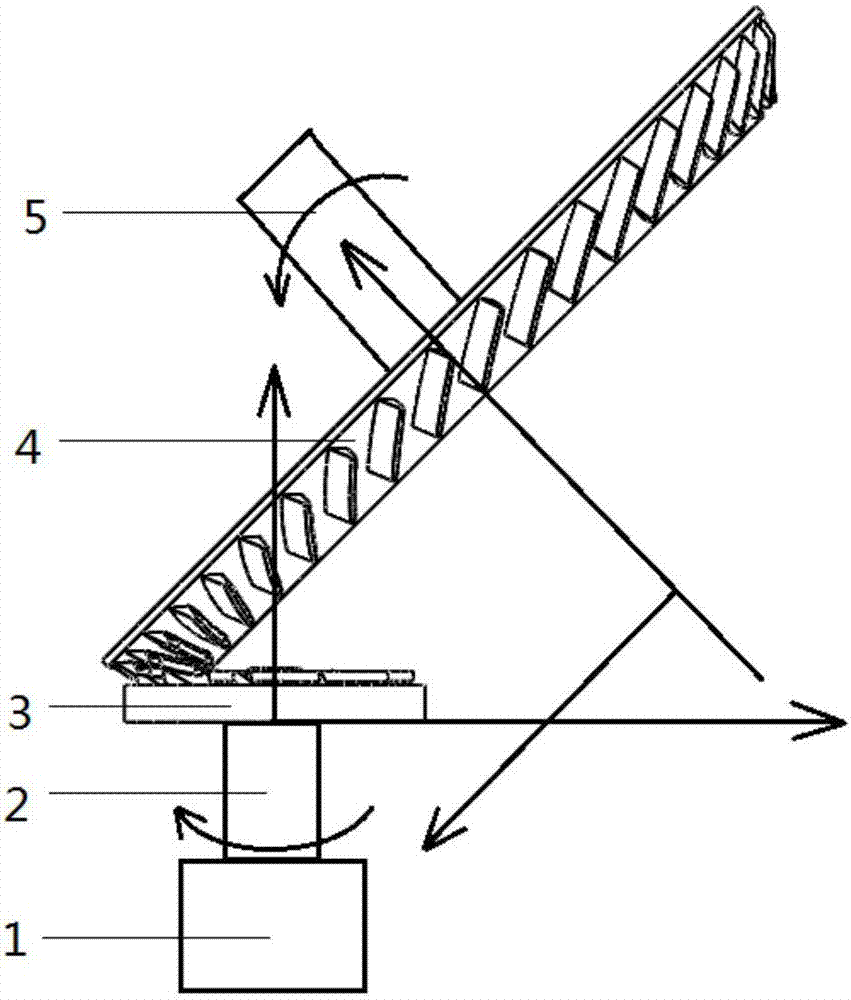

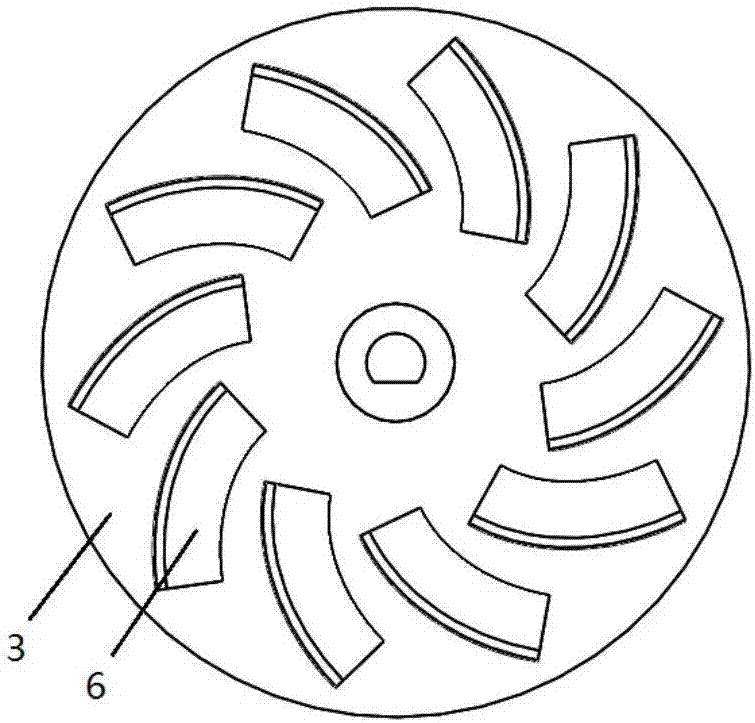

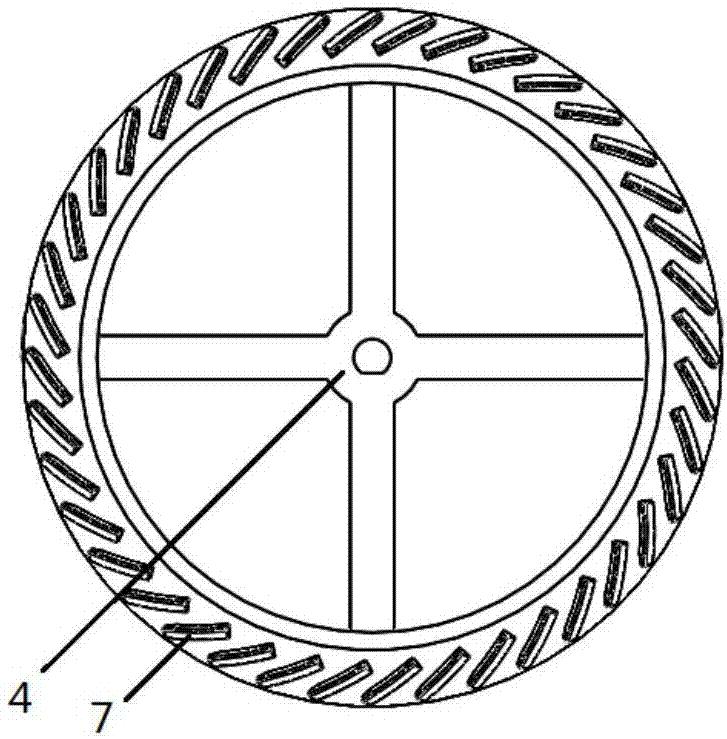

[0077] Implementation example: wire gear pair suitable for 3D printing

[0078] In this implementation case, in order to ensure the rigidity of the wire teeth, the cross section of the active wire teeth is designed as a diagonally supported structure. The contact line is on the left side of the wire gear base, and the right side is the supporting structure. To save material under the premise of maintaining rigidity, the wire tooth adopts a partial circular cross section. Such as Figure 5 shown.

[0079] In the above two formulas: the parameter equation of the active contact line is

[0080] The given design parameters are θ=135°, m=10, n=100, a=10, b=10, i 21 =0.25, Z 1 =10, Z 2 = 40, r 1 = 2, r 2 =2.

[0081] According to the above method, the equation of the tooth contact line of the driven wire is obtained as:

[0082]

[0083] The equation of the center line of the active wire tooth is:

[0084] The equation of the tooth centerline of the driven line is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com