Hydraulic testing gun

A technology of hydrostatic test and gun seat, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc. It can solve the problems of water leakage, synchronous production, occupying space, etc., and achieve increased grip comfort, good stability, Use flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

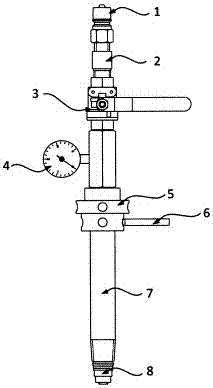

[0012] A hydraulic test gun, comprising a gun base 5, the front of the gun base 5 has a hand-held rod 7, the front end of the hand-held rod 7 has a multi-stage threaded head 8, the tail of the gun base 5 is connected with a pressure gauge 4, and the rear of the pressure gauge 4 Connected with on-off valve 3, on-off valve 3 is a stainless steel ball valve. The rear end of the switch valve 3 is equipped with a quick connector 1. In the embodiment, the quick connector 1 is connected to the switch valve through the intermediate connector 2, so that the daily replacement of the easily damaged quick connector 1 can be ensured, and the intermediate connector 2 can be used to replace the quick connector 1. The replacement is the hydraulic test gun to change the size of the quick connector 1 without changing the switch valve 3 to change the connector. Quick connector 1 is connected to the booster pump. As long as the multi-stage thread head 8 is used to change and use the test gun acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com