Patents

Literature

36results about How to "Implement stress testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

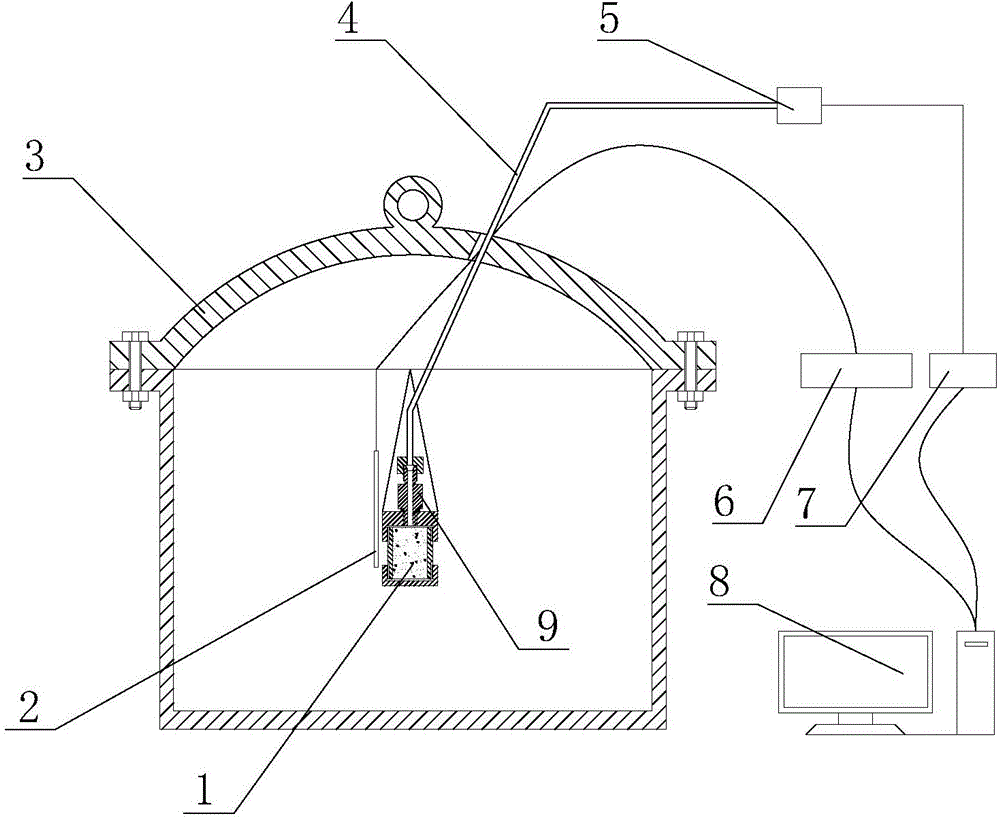

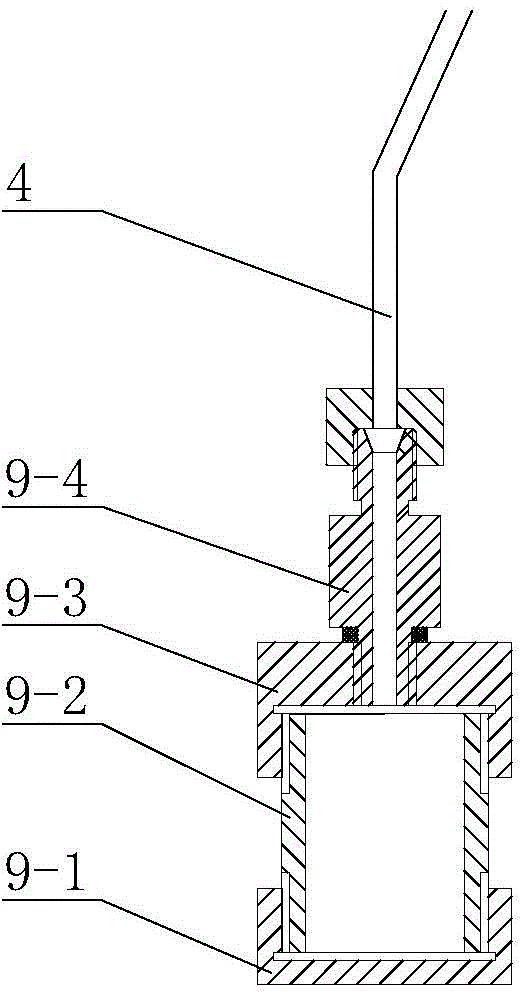

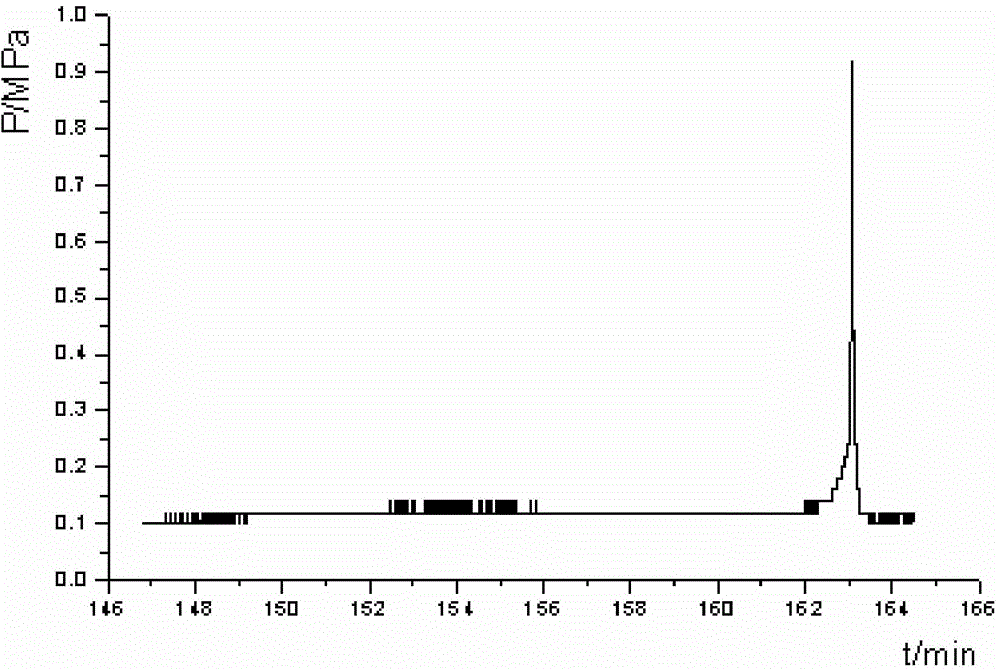

Method for testing pressure during heating process of explosive and propellant columns

InactiveCN104931531ASolve the problem of not being able to work at high temperature for a long timeImplement stress testingMaterial exposibilityEngineeringGuide tube

The invention discloses a method for testing the pressure during the heating process of explosive and propellant columns. The method comprises the following steps: placing a simulated cook-off bomb equipped with the explosive and propellant columns in an anti-explosion heating box, testing the pressure in the simulated cook-off bomb, and arranging a temperature sensor in the anti-explosion heating box to monitor and regulate and control the temperature variation in the anti-explosion heating box during the test process; hermetically connecting an upper end cover of the simulated cook-off bomb to a pressure sensor through a guide pipe, and mounting the pressure sensor outside the anti-explosion heating box; respectively connecting the temperature sensor and the pressure sensor to a corresponding temperature instrument and a corresponding pressure instrument, and connecting the temperature sensor and the pressure sensor to a computer. The method is suitable for testing the pressure during the heating process of various explosive and propellant columns, the variable curve of the pressure along with time during the heating process is recorded, the pressure value in the simulated cook-off bomb when the explosive and propellant columns are subjected to heat explosion is determined, and the severe degree of explosion when the explosive and propellant columns explode under the heat stimulus action can be assessed.

Owner:XIAN MODERN CHEM RES INST

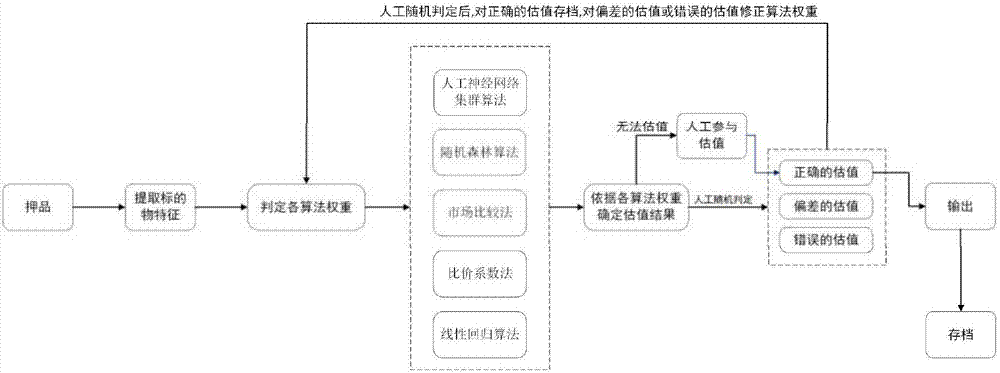

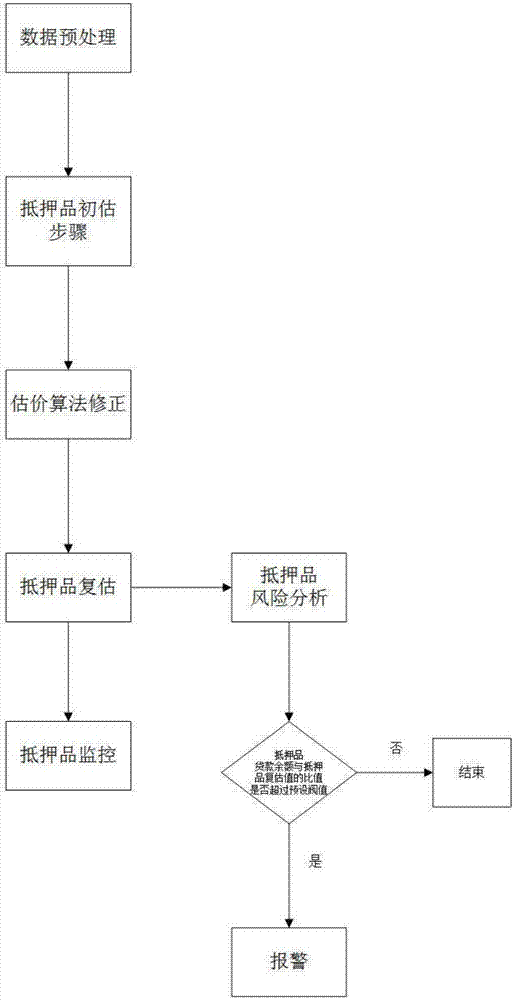

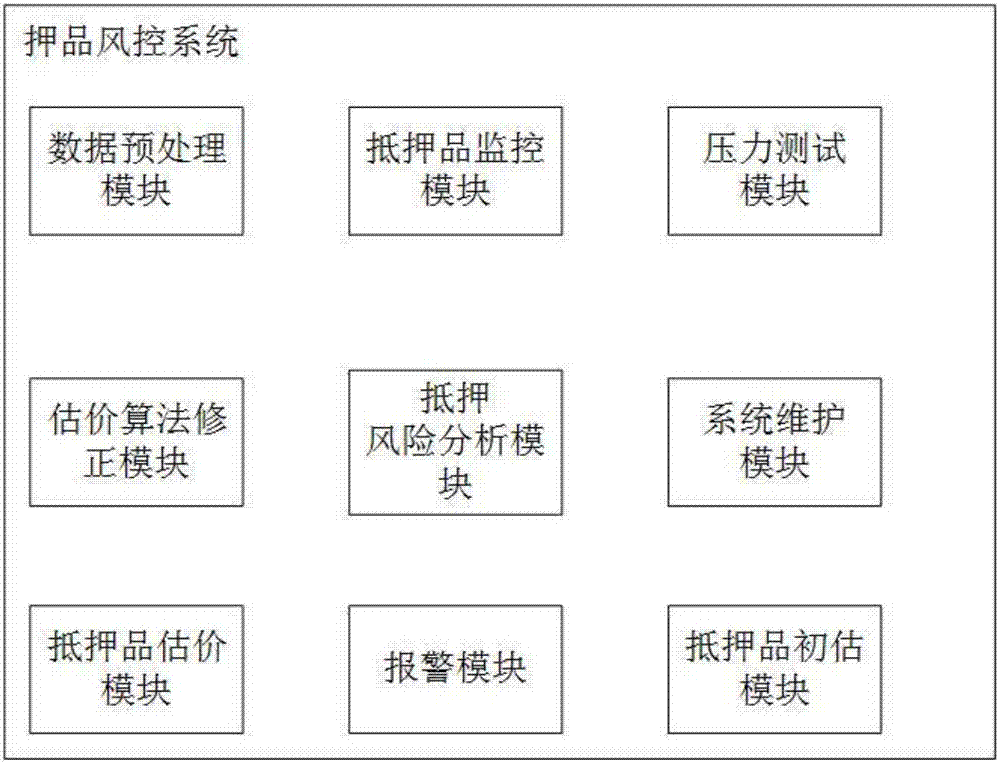

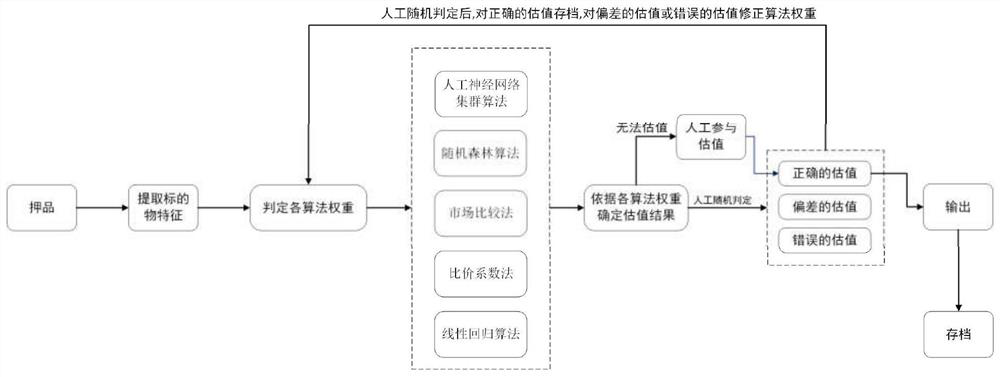

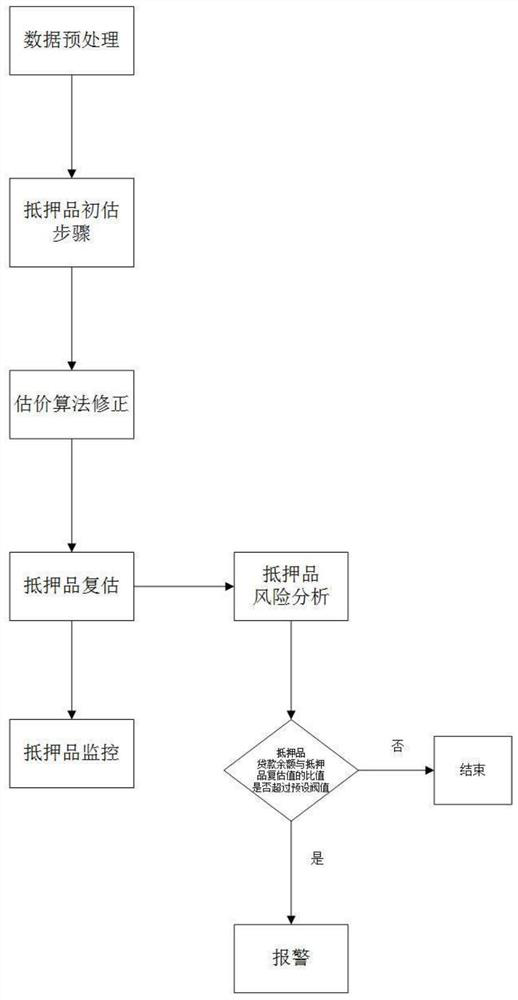

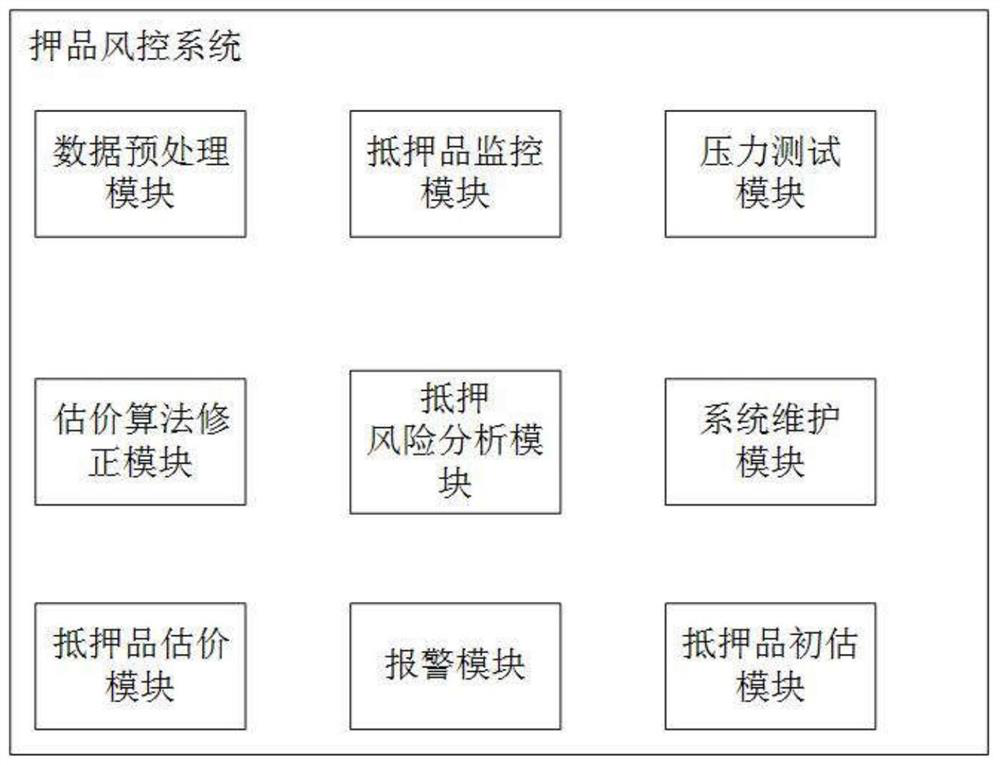

Real estate collateral risk control method and system, and storage medium

The invention establishes an intelligent evaluation algorithm system based on collateral big data. A value evaluation process uses two networks. A first network is used for determining an evaluation algorithm the most suitable for the collateral and increasing the evaluation weight of the algorithm. The second network is used for collecting user feedback information. Whatever correct evaluation, deviated evaluation, or erroneous evaluation, on the one hand, a computer automatically analyzes and records the evaluations, and on the other hand, a worker participates to help the computer correct the deviation or the error, which is similar to a deviation or error memory stick, and all evaluations are fed back to the first network. Two networks continuously and cyclically operate, learn the correctness and the wrongness, form experience after long-time accumulation, perform continuous improvement, and increasingly improve the accuracy rate in order to achieve automatic batch precise evaluation, and achieve risk analysis based on the precise evaluation.

Owner:重庆汇集源科技有限公司

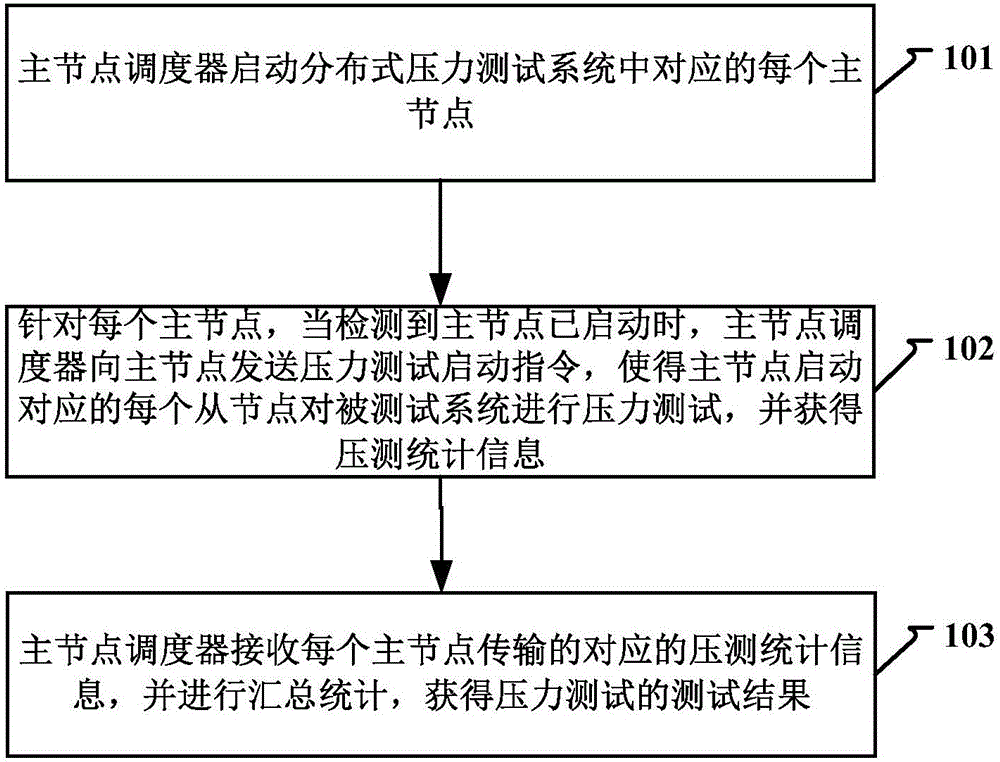

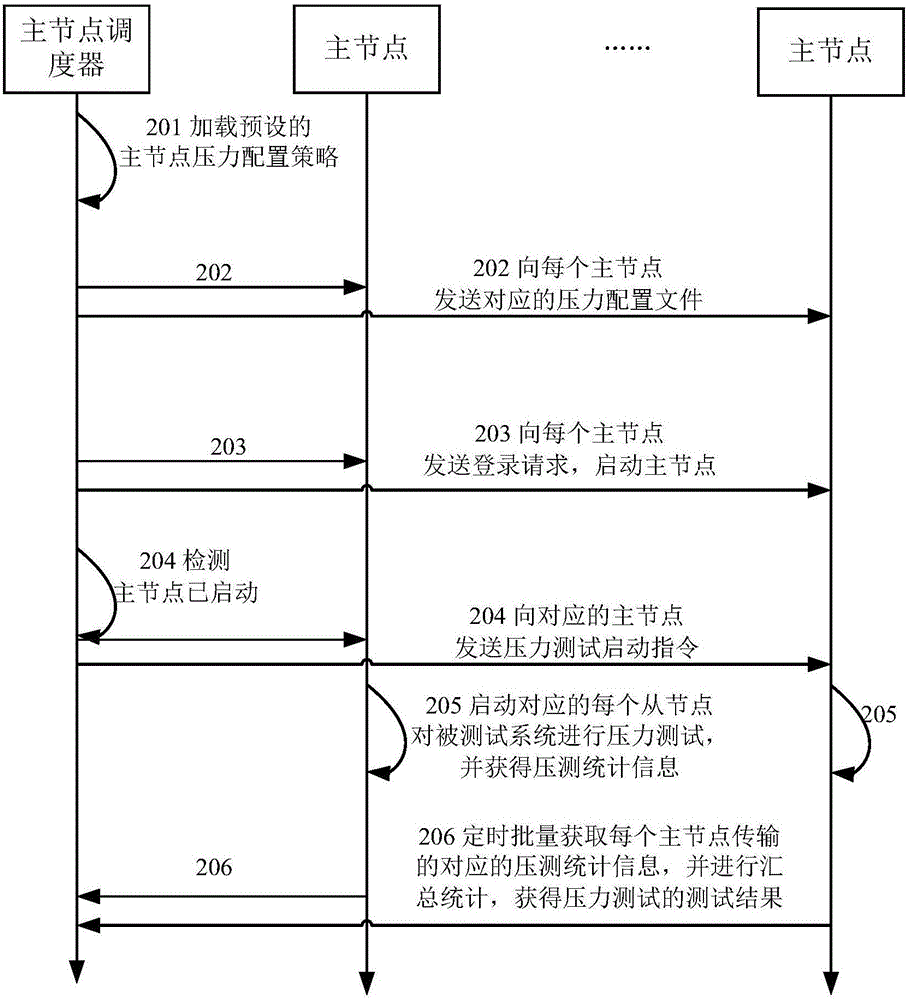

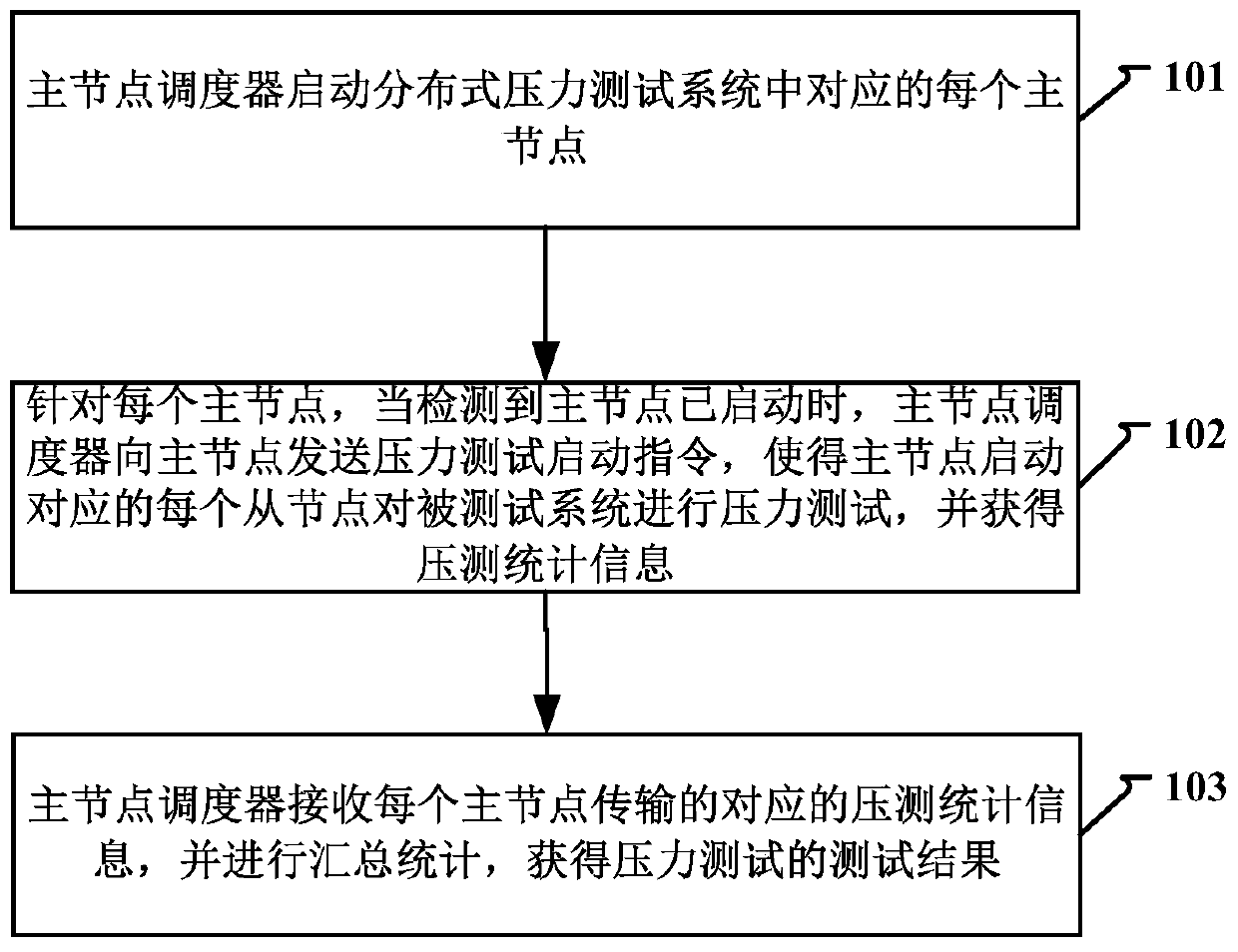

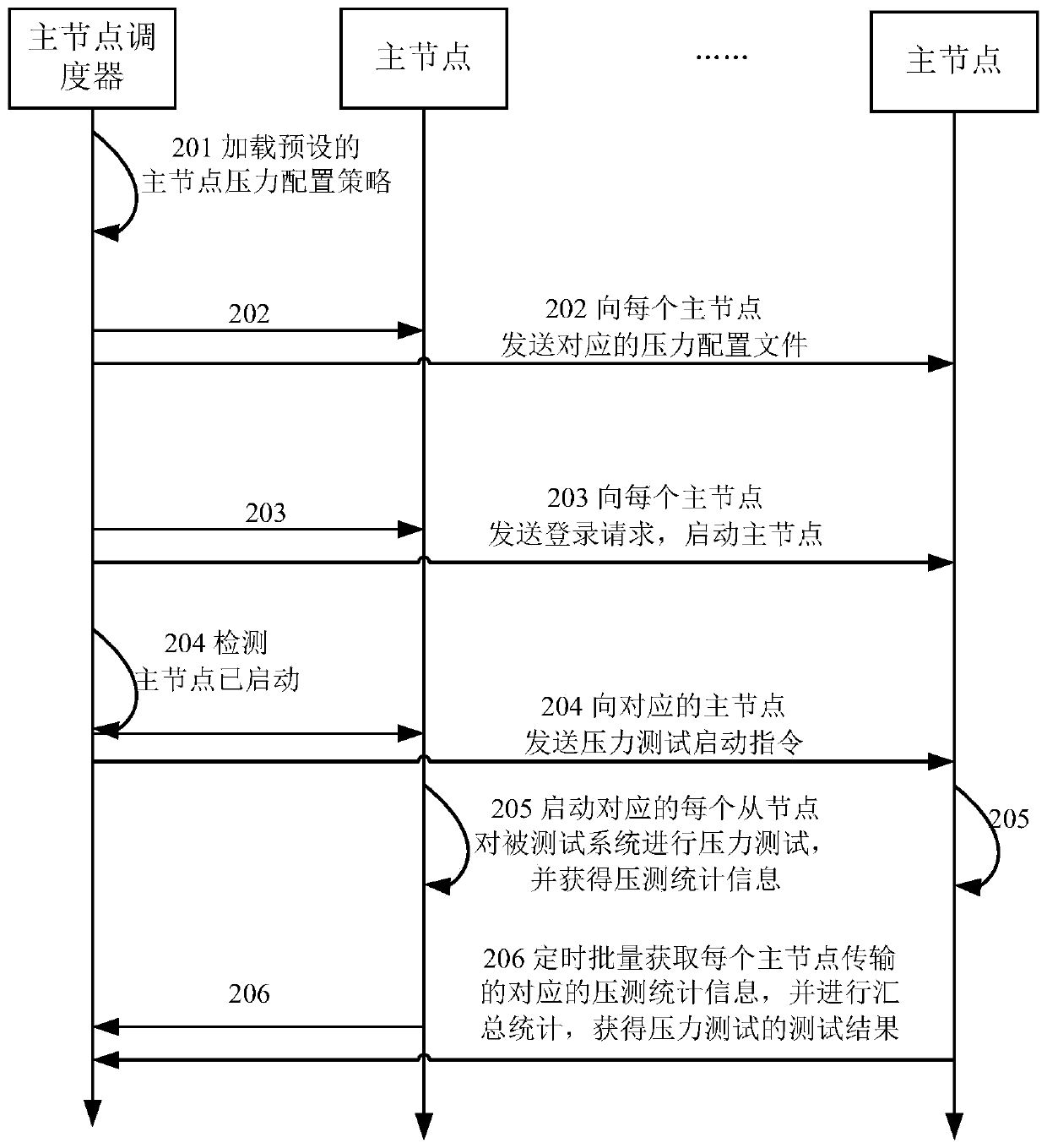

Pressure test method, device and system

ActiveCN106506255AReduce the chance of becoming a bottleneckSolve the problem of insufficient upper limit of expansion capacityData switching networksSystem under testComputer science

The invention discloses a pressure test method, a pressure test device and a pressure test system, used for improving scale and efficiency of a pressure test. The method is applied to a distributed pressure test system which comprises a main node scheduler and at least one main node, wherein each main node corresponds to at least one slave node. The method comprises the following steps: the main node scheduler starts each corresponding main node; for each main node, when the main node is started is detected, a pressure test start command is sent to the main node, so that the main node starts each corresponding slave node to perform the pressure test on a system under test, and acquires pressure test statistical information; and the corresponding pressure test statistical information transmitted by each main node is received, and summary statistics is performed, and thus a test result of the pressure test is acquired.

Owner:MICRO DREAM TECHTRONIC NETWORK TECH CHINACO

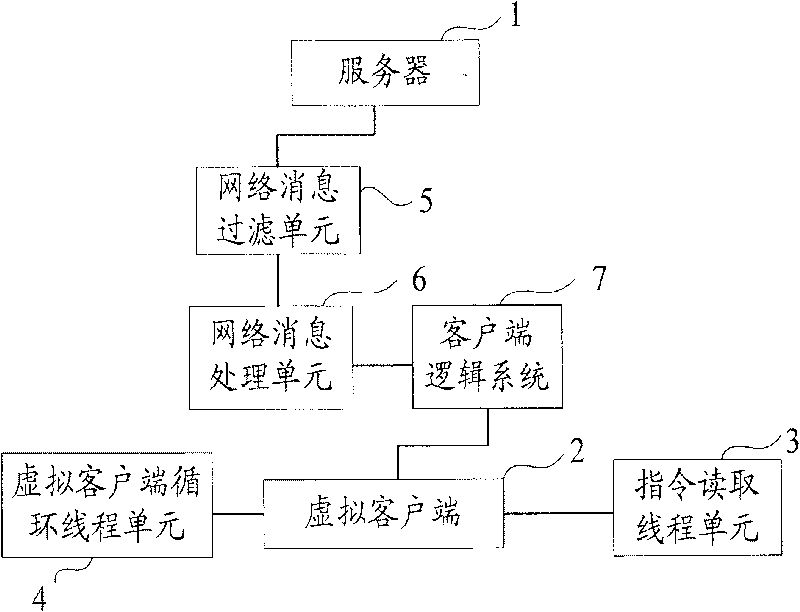

Network server pressure testing method and system

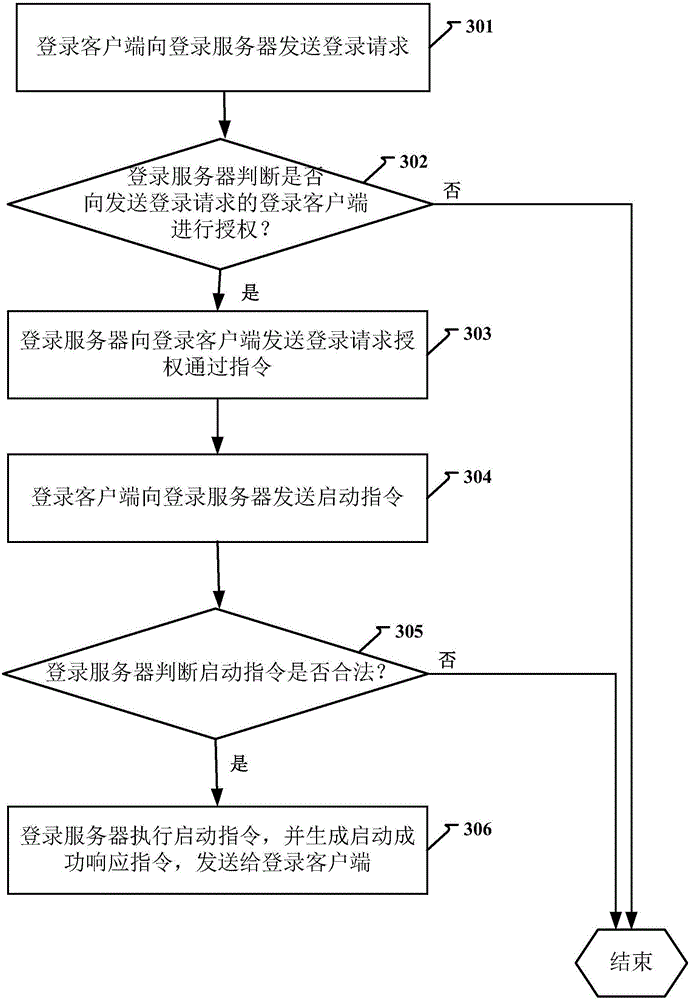

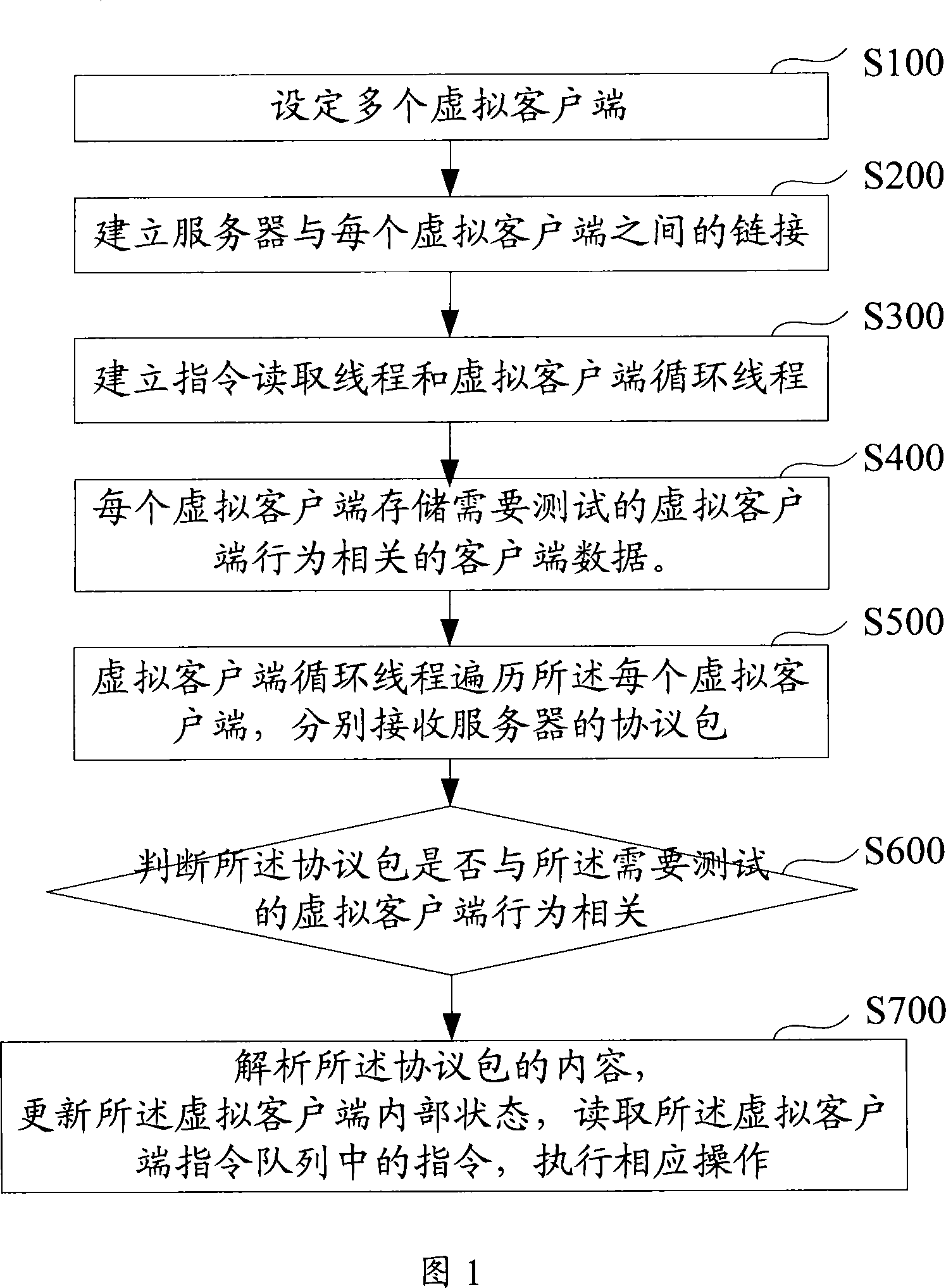

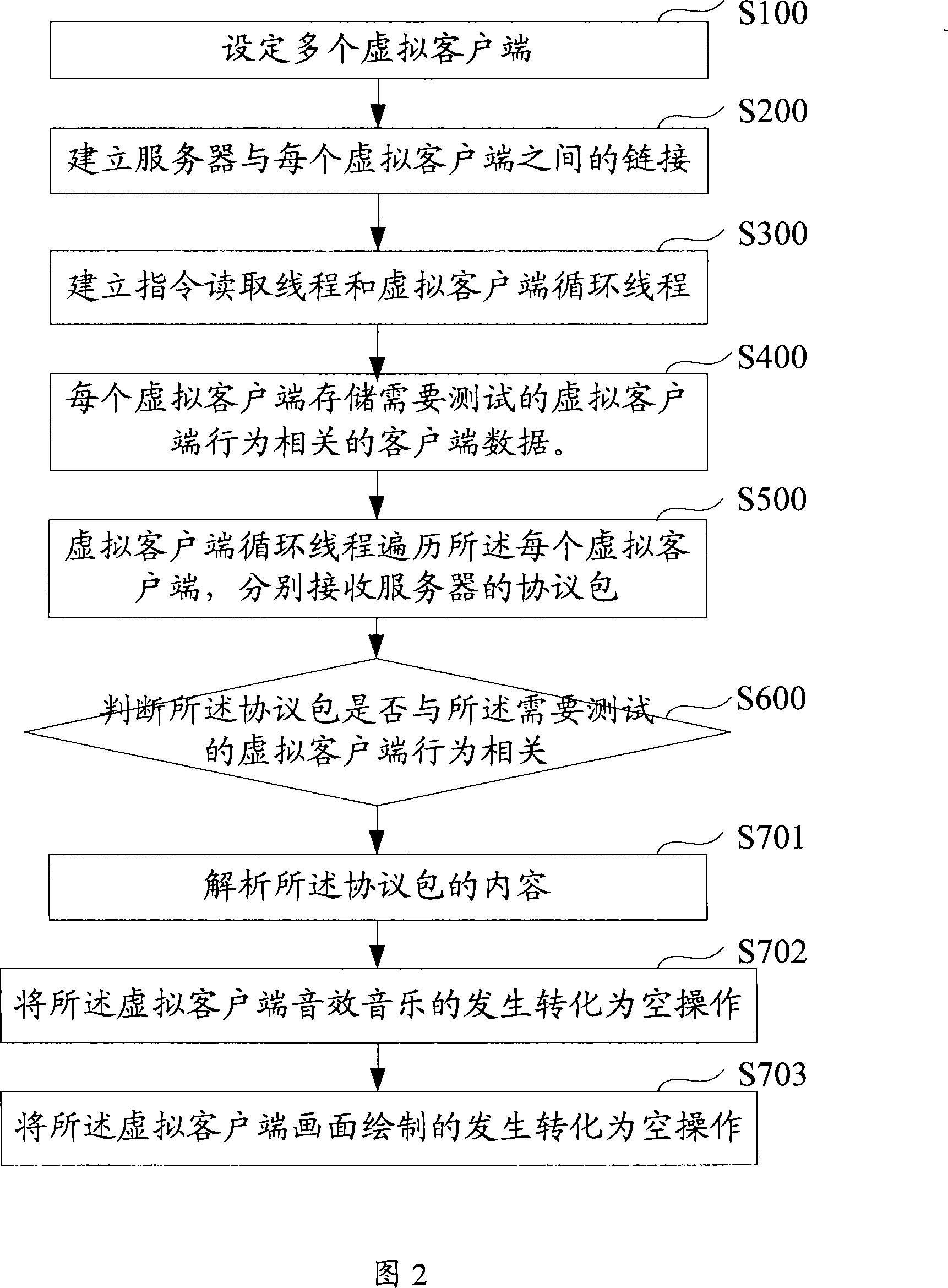

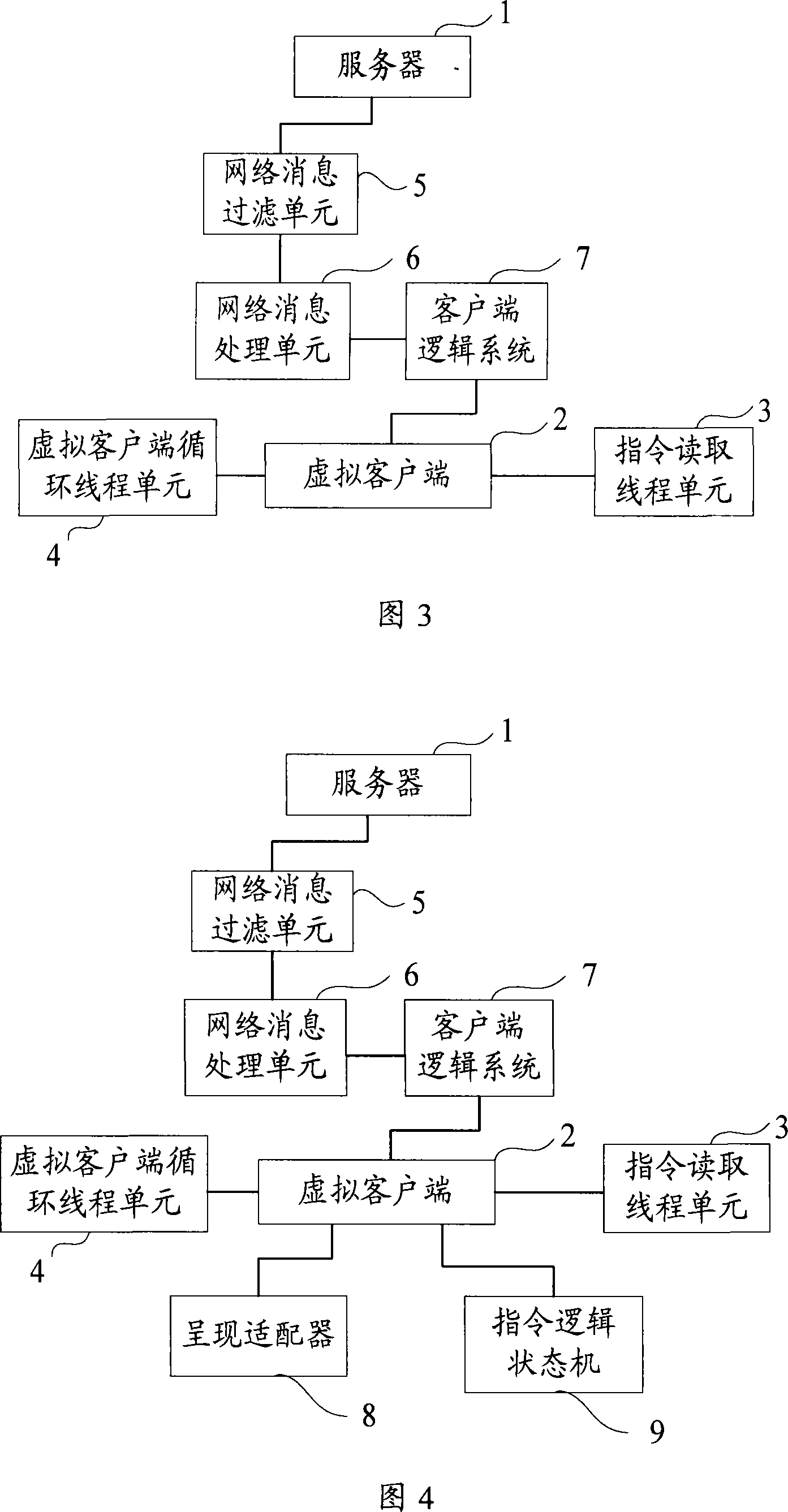

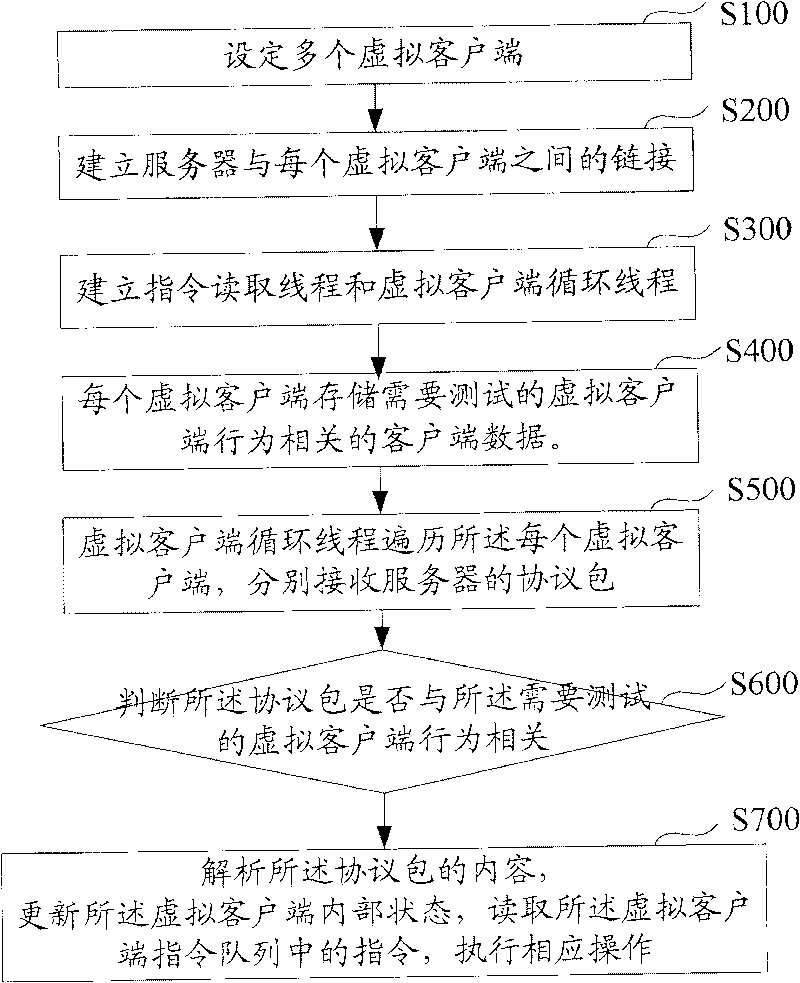

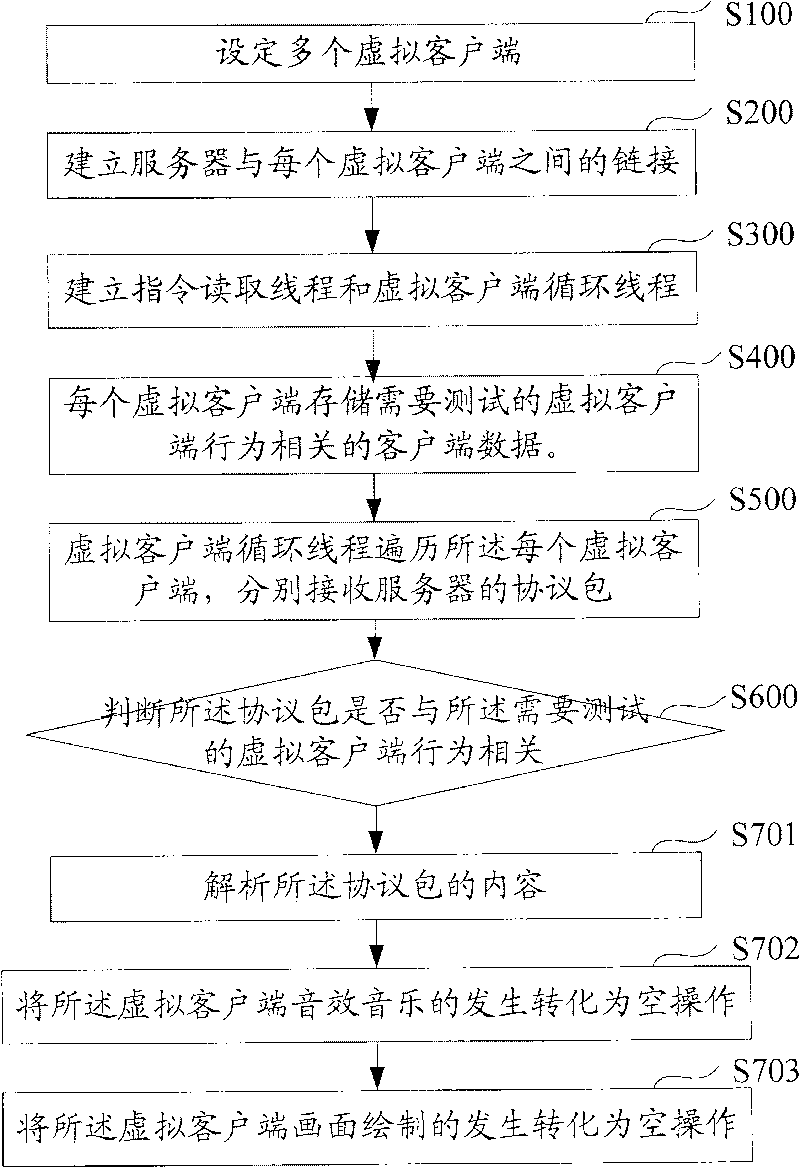

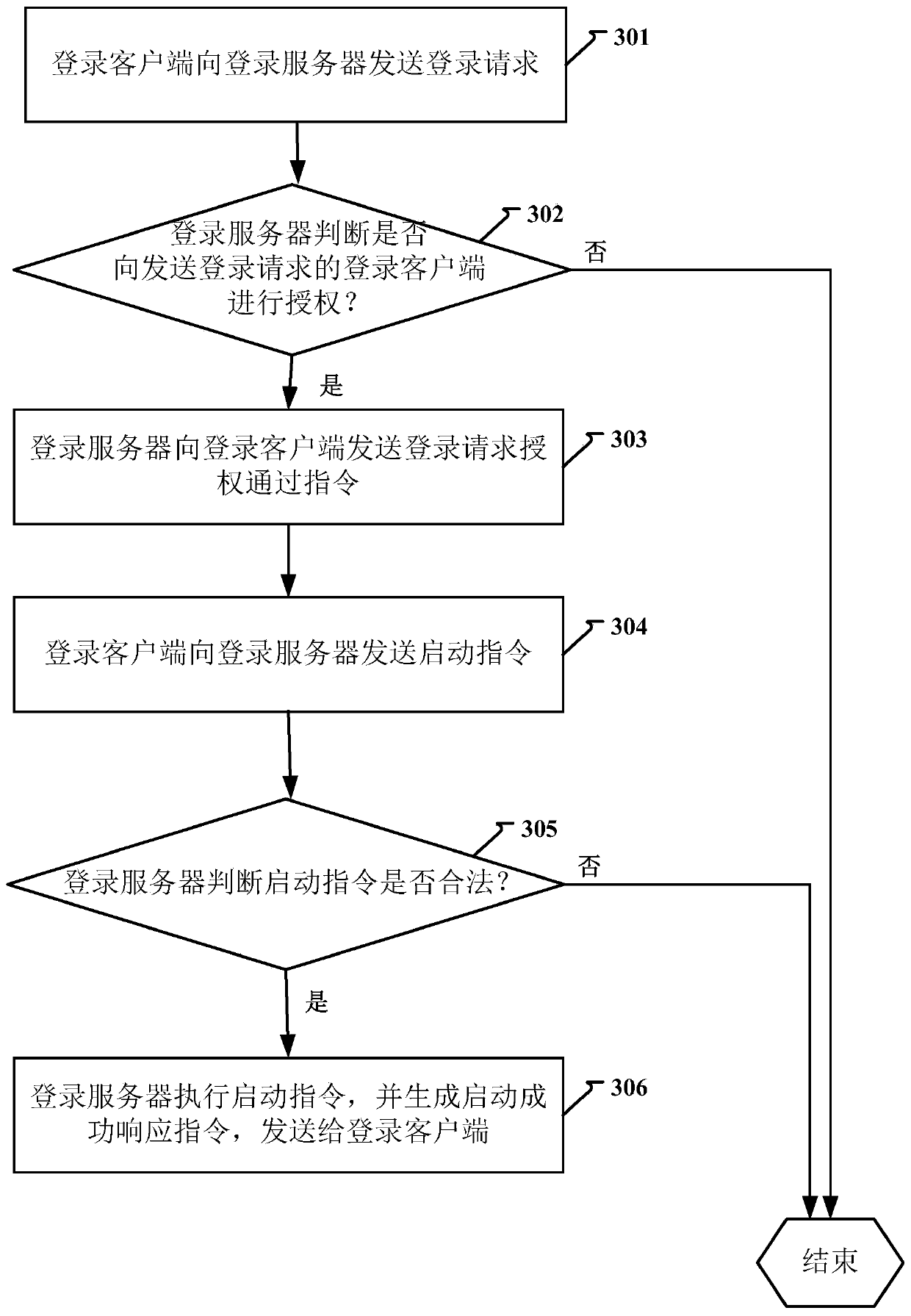

ActiveCN101184001AImplement stress testingAvoid early exposureData switching networksTest requirementsClient-side

The invention discloses a test method for the workload test of the network service, comprising the following steps: A: set a plurality of virtual client sides; B: establish the links between the server and each virtual client side; C: establish the instruction reading thread and the circulation thread of the virtual client sides; D: each virtual client side stores the client side data behaviorallyrelated with the virtual client sides of the required test; E: the circulation thread of the virtual client sides traverses each virtual client side, receives the protocol package of the server respectively; F: judge whether the protocol package is behaviorally related with the virtual client sides of the required test, if yes, execute the step G, or end; G: analyze the content of the protocol package, update the internal status of the virtual client sides, read the instruction of the virtual client side instruction sequence, execute the corresponding operation. The invention provides a workload test method and a system of the network service, which are used to meet the test requirement of the network service, and avoids the exposure of the network product in advance.

Owner:BEIJING KINGSOFT SOFTWARE +1

Display screen detection device

InactiveCN113029812ASpeed up the detection progressAvoid scratch damageMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesMechanical engineeringPhysics

A display screen detection device disclosed by the present invention comprises a box body, the upper surface of the box body is fixedly connected with a bottom plate, the middle part of the upper surface of the bottom plate is fixedly provided with two mounting seats, the upper surfaces of the two mounting seats are fixedly provided with first electric cylinders, and the two first electric cylinders are oppositely arranged. A concave sliding groove is formed in the middle of the upper surface of the bottom plate. The first electric cylinders are matched with the lifting assemblies, so that the display screen can be tested at different bending angles, the detection device is suitable for bending tests of display screens of different sizes, damage-free tests are achieved when the display screen is tested through the adsorption mechanism, the phenomenon that the display screen is scratched and damaged during testing is avoided, the air cylinder is matched with the second electric cylinder and the supporting plate, pressure testing of the display screen is achieved, a detector does not need to place the display screen on another test workpiece for testing, and the detection efficiency is greatly improved.

Owner:林贵滨

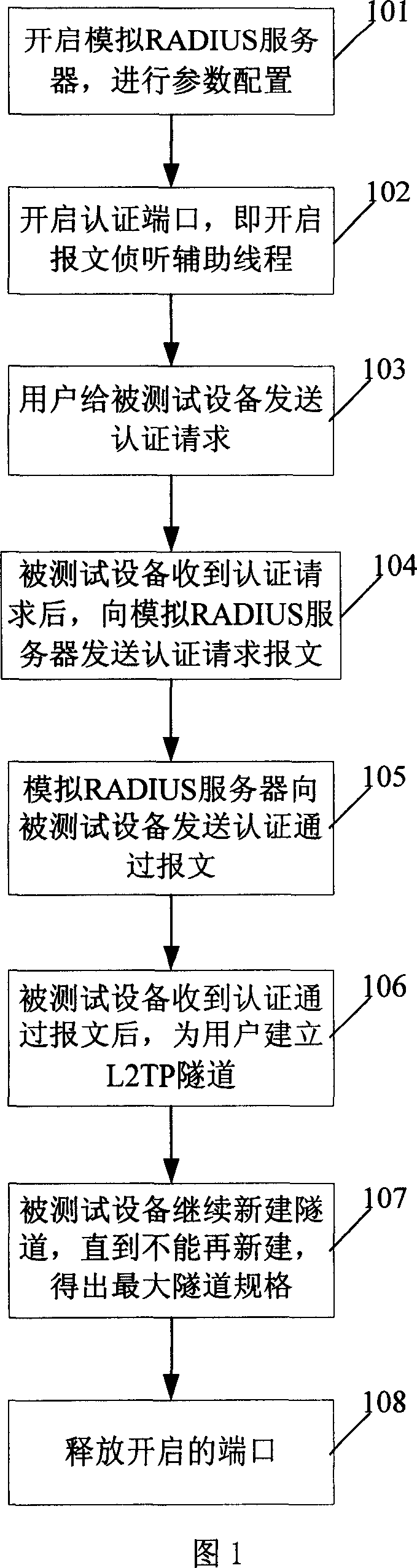

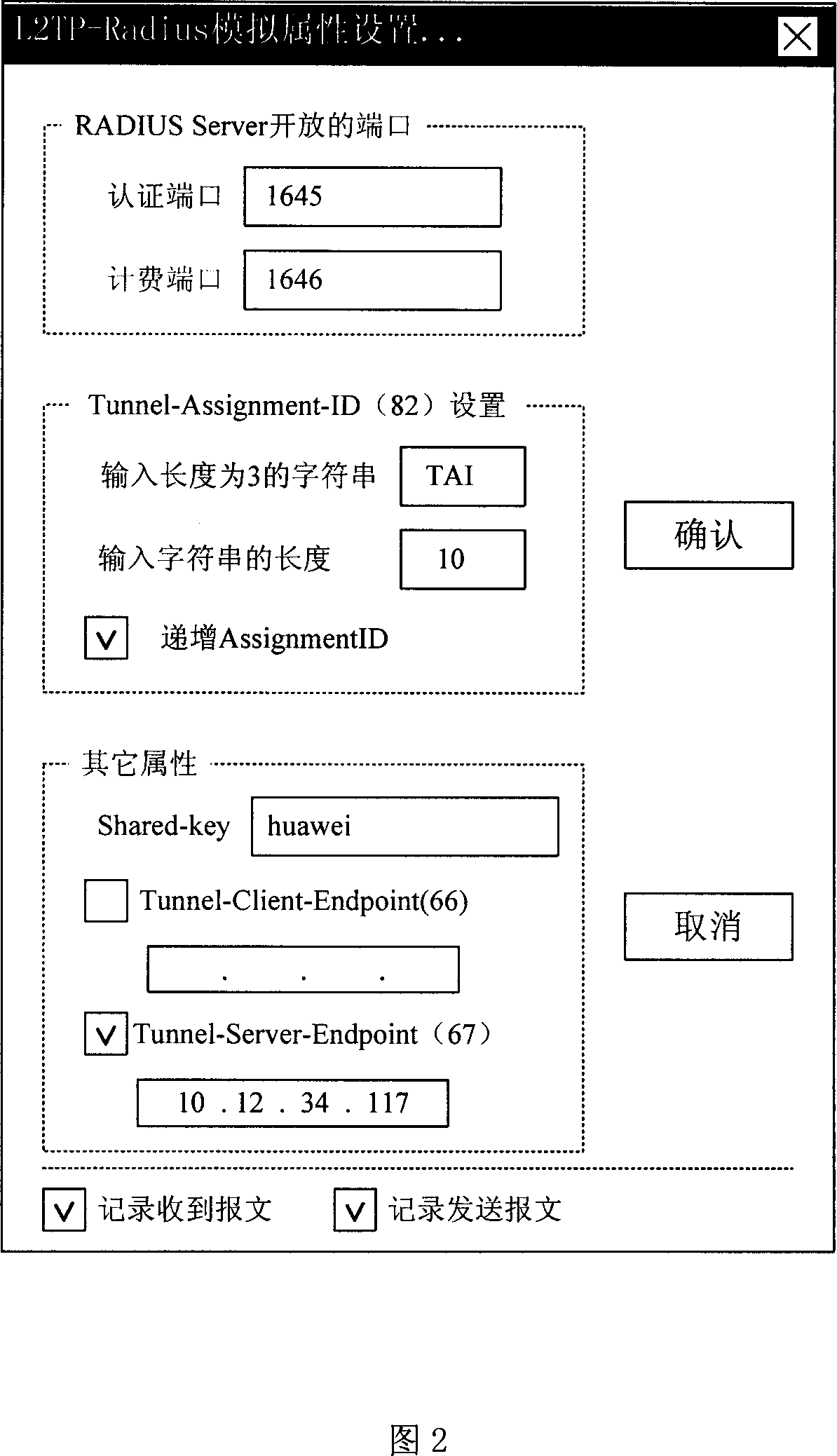

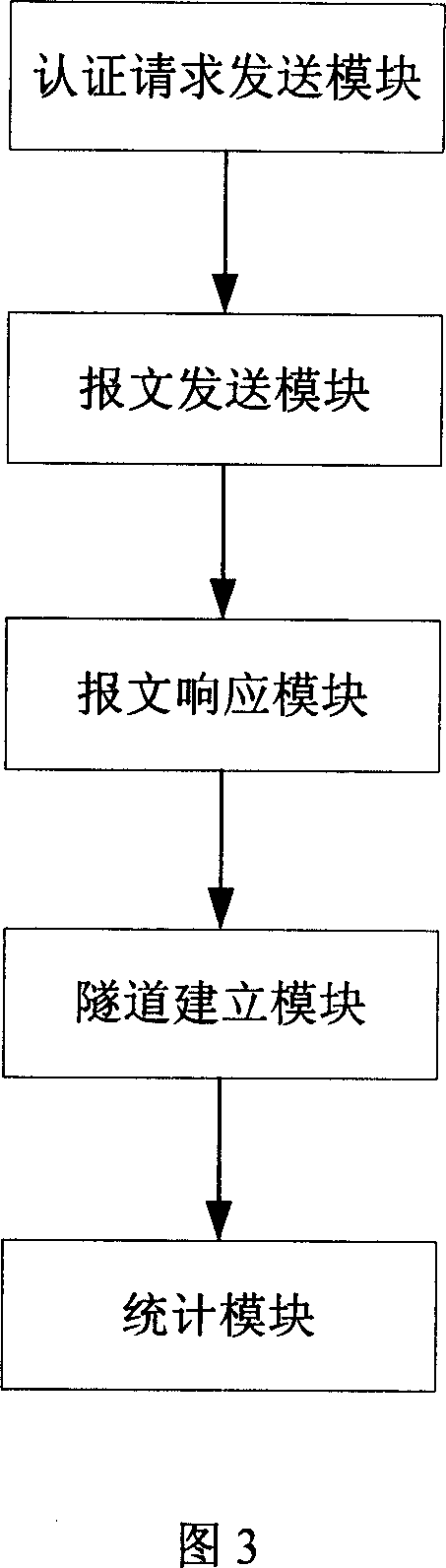

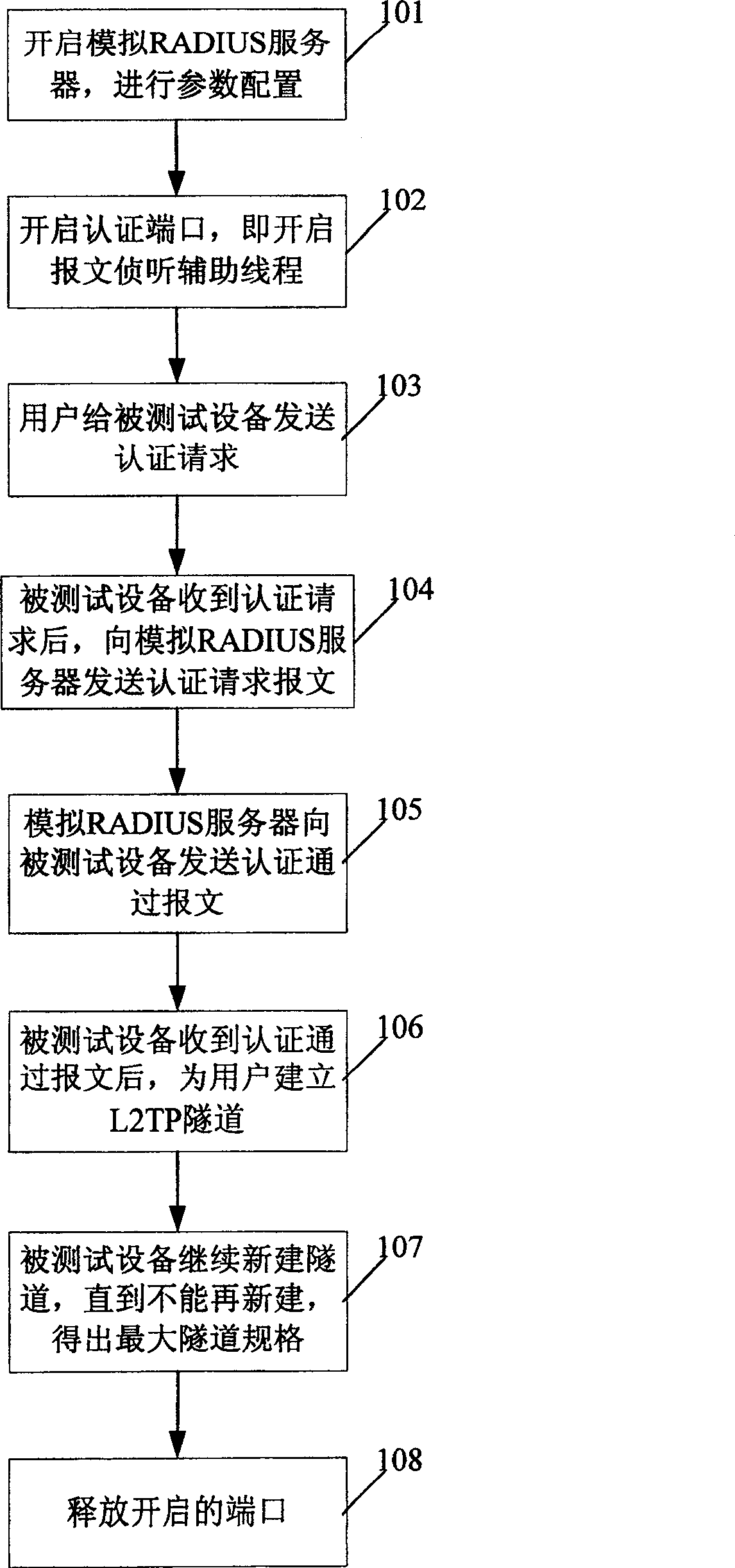

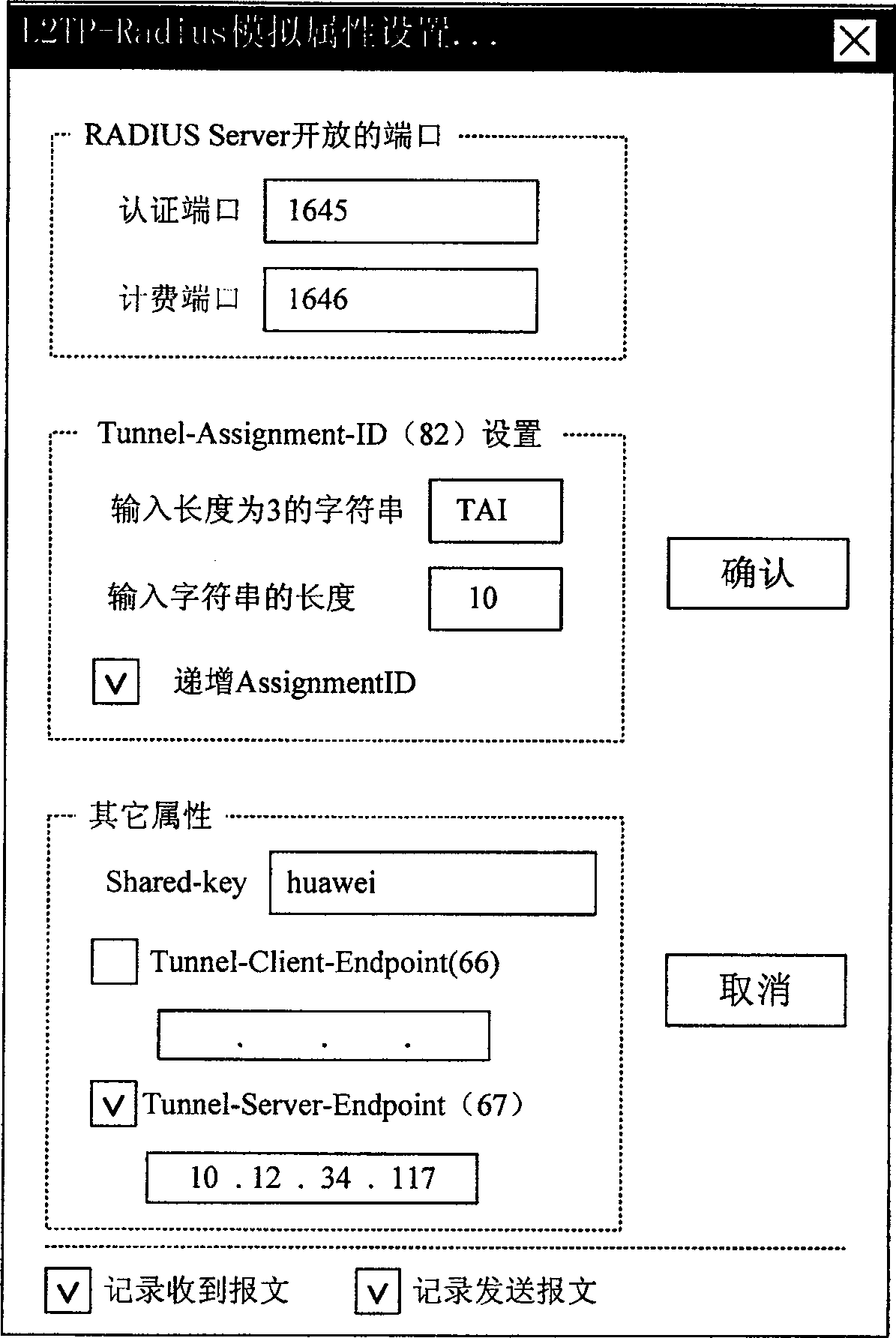

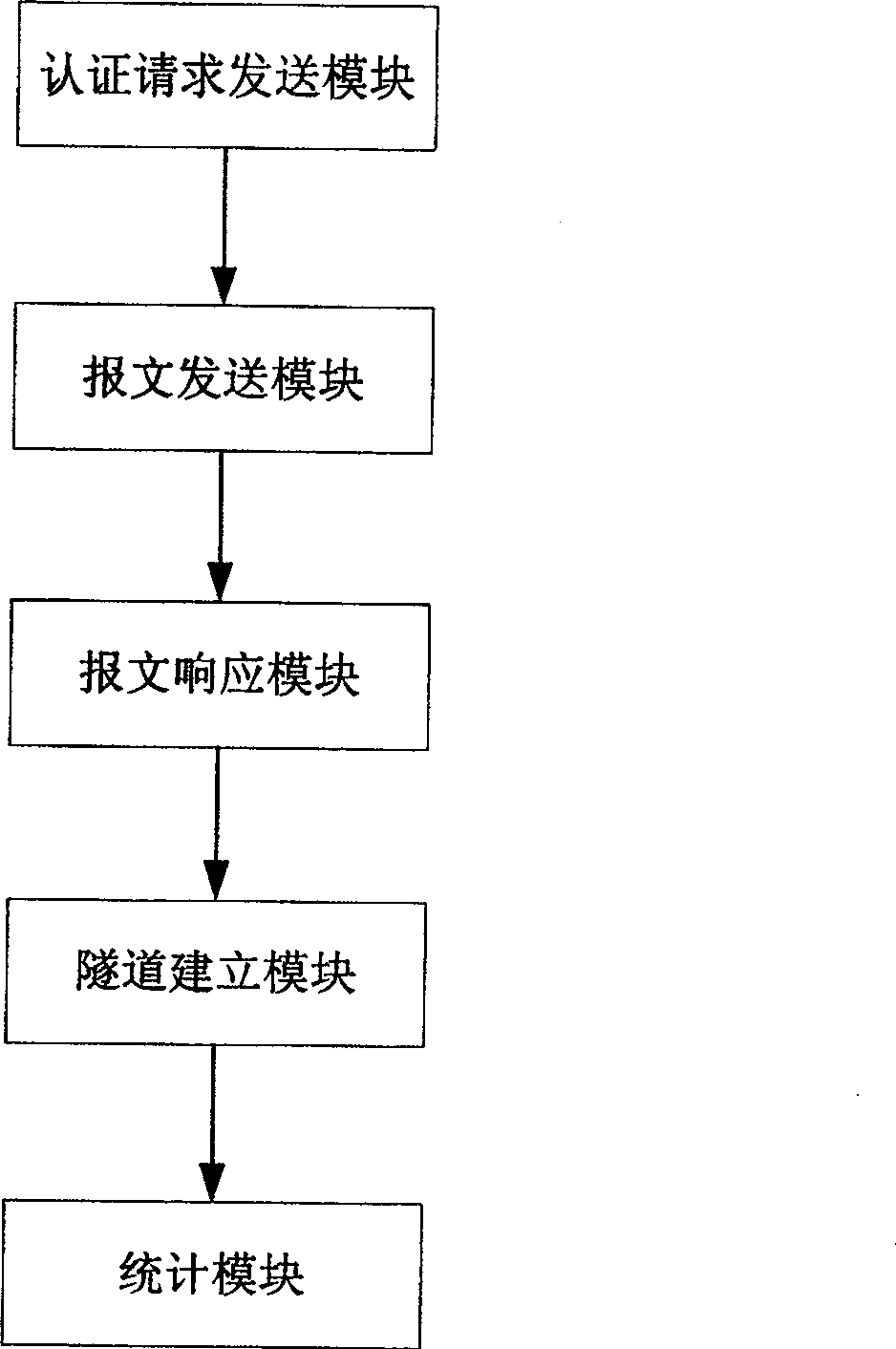

A test method and system for L2TP tunnel specification

InactiveCN101009606AImplement stress testingReduce testing costsData switching networksComputer hardwareTest facility

The provided test method forL2TP specification standard in digital communication test field comprises: setting an analog server, configuring port parameters, starting the assist thread for monitoring message, and returning user certification request as certified message to the target device; allowing the certified user on line and building L2TP channel, accounting and obtaining the maximal channel specification. It also provides a test system with corresponding modules for former steps. This invention can be used for target device as LAC or LNS, and reduces test cost.

Owner:HUAWEI TECH CO LTD

Method for using negative pressure perforation technology for realizing pressure recovery well logging interpretation

InactiveCN104278985AImplement stress testingReliable test resultsSurveyConstructionsWell loggingPressure data

The invention discloses a method for using a negative pressure perforation technology for realizing pressure recovery well logging interpretation. The method comprises the steps that first, a negative pressure perforation tubular column capable of realizing a negative pressure perforation process is obtained; second, a storage type pressure and temperature instrument is connected to the position near a perforation gun on the negative pressure perforation tubular column, and continuously records temperature and pressure data obtained after perforation according to an oil deposit design; third, formation fluid flows into a shaft after the perforation gun is fired, the rising height of the liquid level inside an oil tube is continuously recorded and calculated, and the total amount of liquid flowing out of a formation is calculated; fourth, a perforating barrel string is taken out after a designed pressure test time; direct reading of the storage type pressure and temperature test data is conducted through software, and various well logging interpretation data results are obtained finally. The method can realize perforation and pressure recovery tests by placing the tubular column for one time, conduct well logging interpretation to obtain various stratum parameters, shorten the formation testing time, avoid pollution to a hydrocarbon reservoir and provide guiding advice and strong data support for following oilfield development work.

Owner:CHINA PETROLEUM & CHEM CORP +1

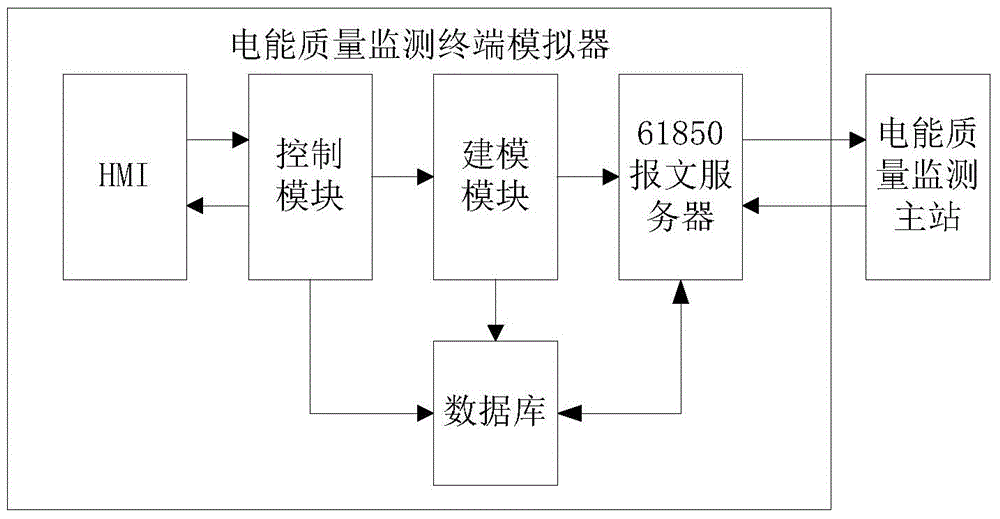

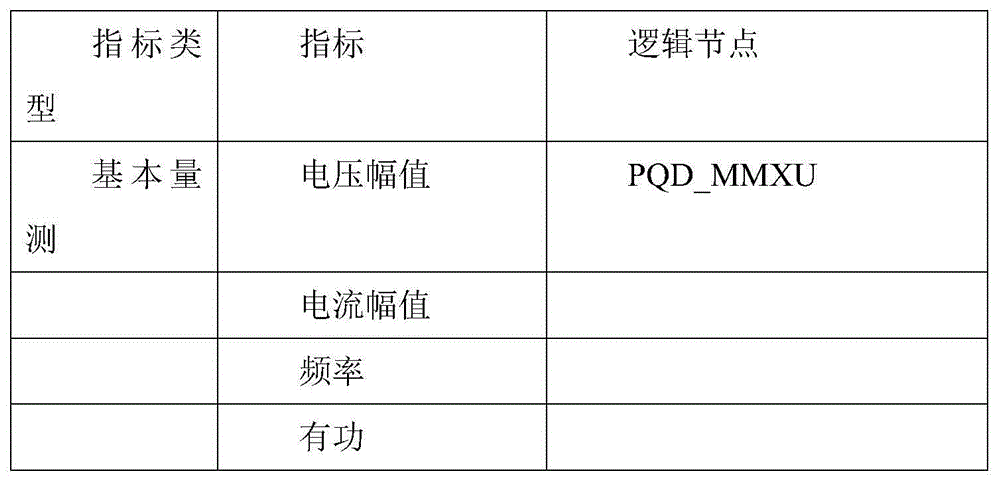

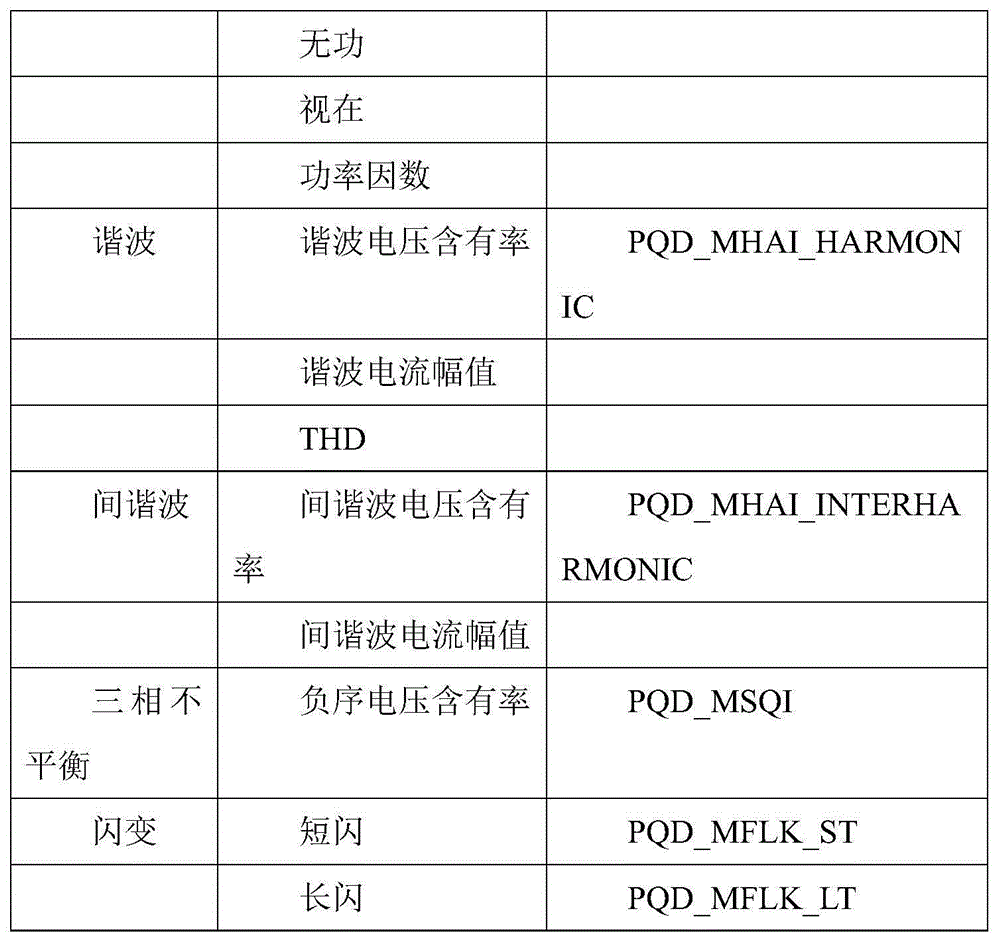

Electric energy quality monitoring terminal simulator

InactiveCN105717472AReduce testing costsShorten the test cycleElectrical measurementsPower qualityPrimary station

The present invention proposes a power quality monitoring terminal simulator, the simulator includes an HMI human-computer interaction module, a control module, a modeling module, an IEC 61850 server and a database; the power quality monitoring terminal simulator is connected to a power quality monitoring master station; The HMI human-computer interaction module, the control module, the modeling module, the IEC 61850 server and the database are connected in sequence. The present invention simulates the communication behavior of all terminals in the entire power quality monitoring system, which can save test equipment, reduce test costs, and shorten the test cycle; through the terminal simulator test, it can ensure that the function and configuration of the power quality monitoring master station are correct, thereby The seamless communication between the actual power distribution terminal and the client system is realized, which ensures the accuracy and reliability of the data transmission of the entire power quality monitoring system. The invention is simple in configuration, easy to implement, and can be quickly configured to complete the input test.

Owner:STATE GRID CORP OF CHINA +1

Pressure test method and device, network equipment and storage medium

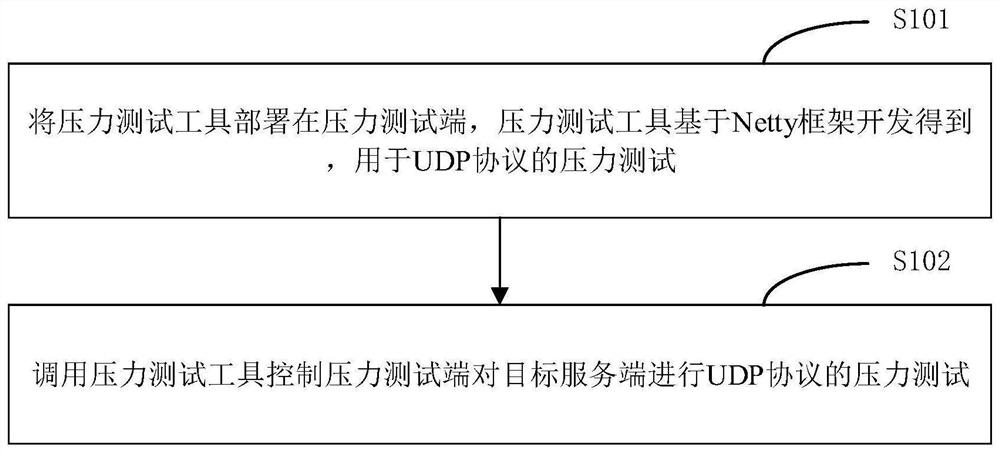

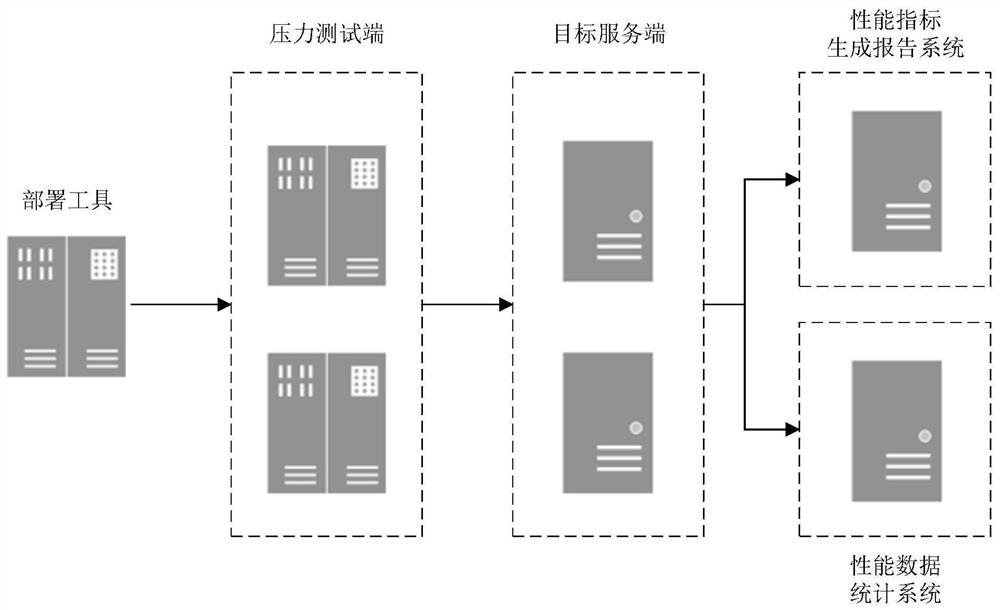

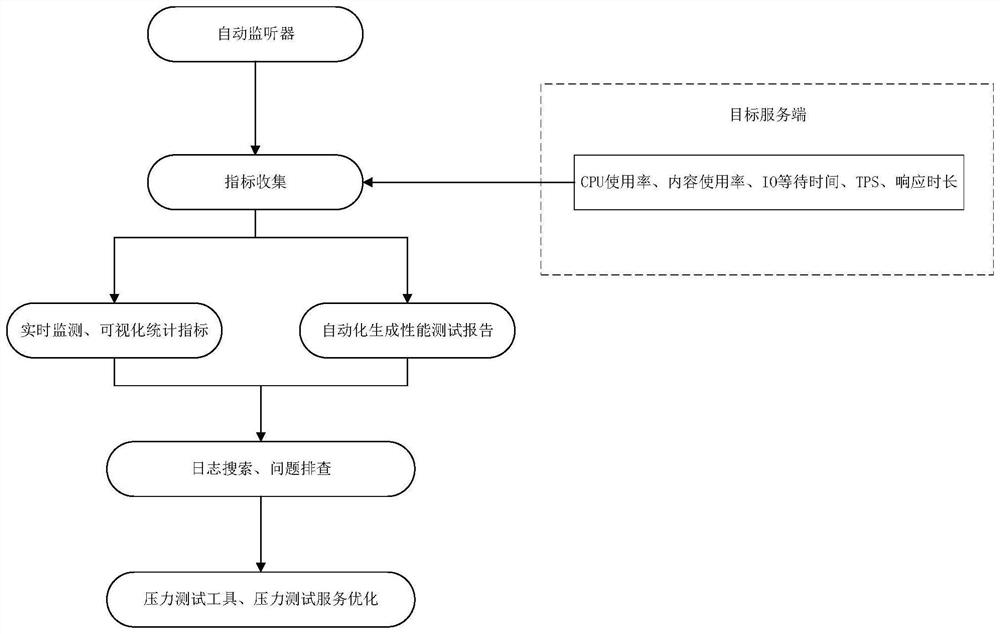

InactiveCN112134754AImplement stress testingHigh degree of automationSoftware testing/debuggingData switching networksEmbedded systemTest set

The embodiment of the invention relates to the technical field of communication, and discloses a pressure test method, which comprises the steps of deploying a pressure test tool at a pressure test end, the pressure test tool being developed based on a Netty framework and being used for a pressure test of the UDP; and calling the pressure test tool to control the pressure test end to perform UDP pressure test on a target server. The embodiment of the invention further discloses a pressure test device, network equipment and a storage medium. According to the pressure test method and device, thenetwork equipment and the storage medium provided by the embodiment of the invention, the pressure test of the UDP can be realized, and the pressure test method and device can be effectively appliedto the pressure test of the UDP.

Owner:CHINA MOBILEHANGZHOUINFORMATION TECH CO LTD +1

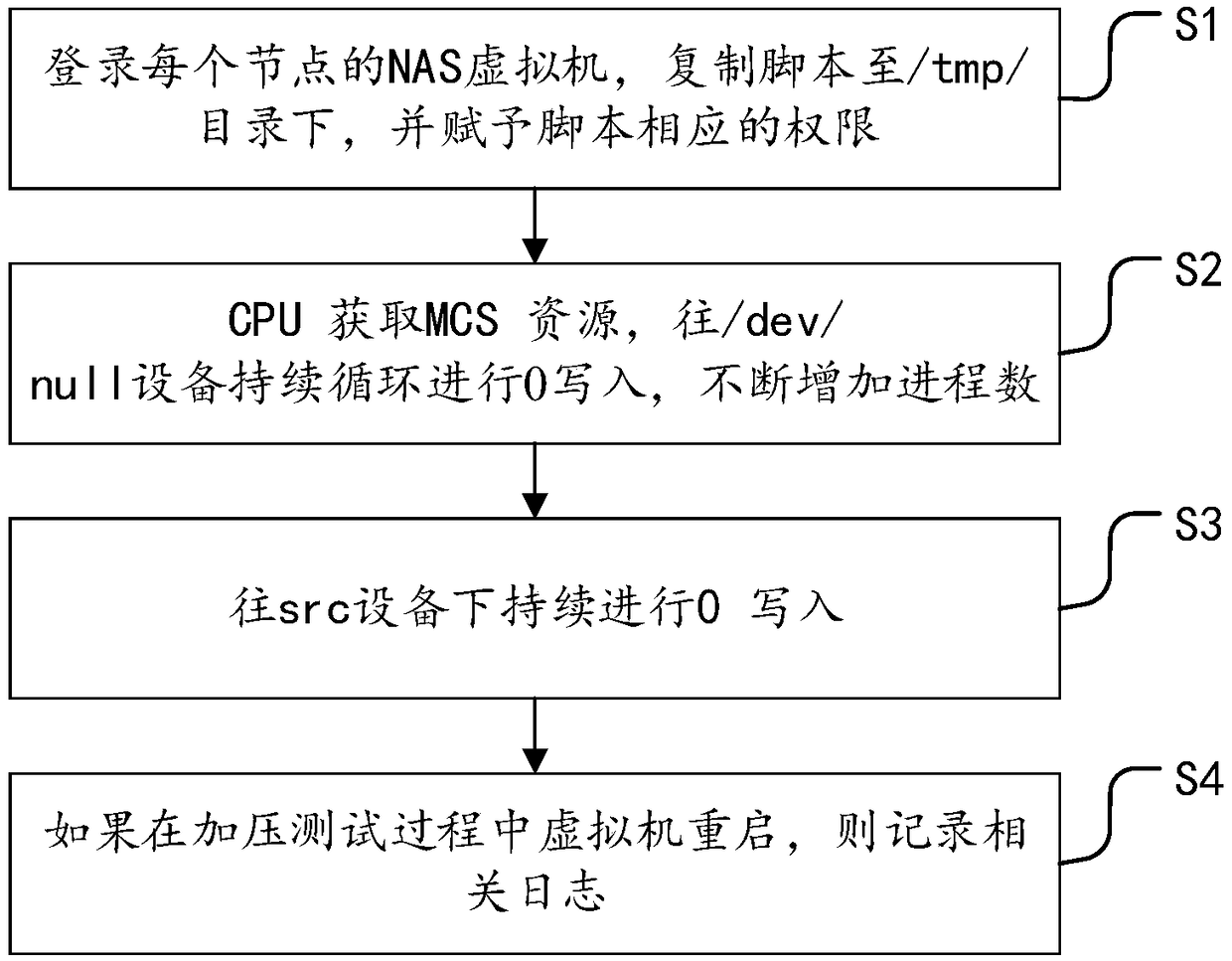

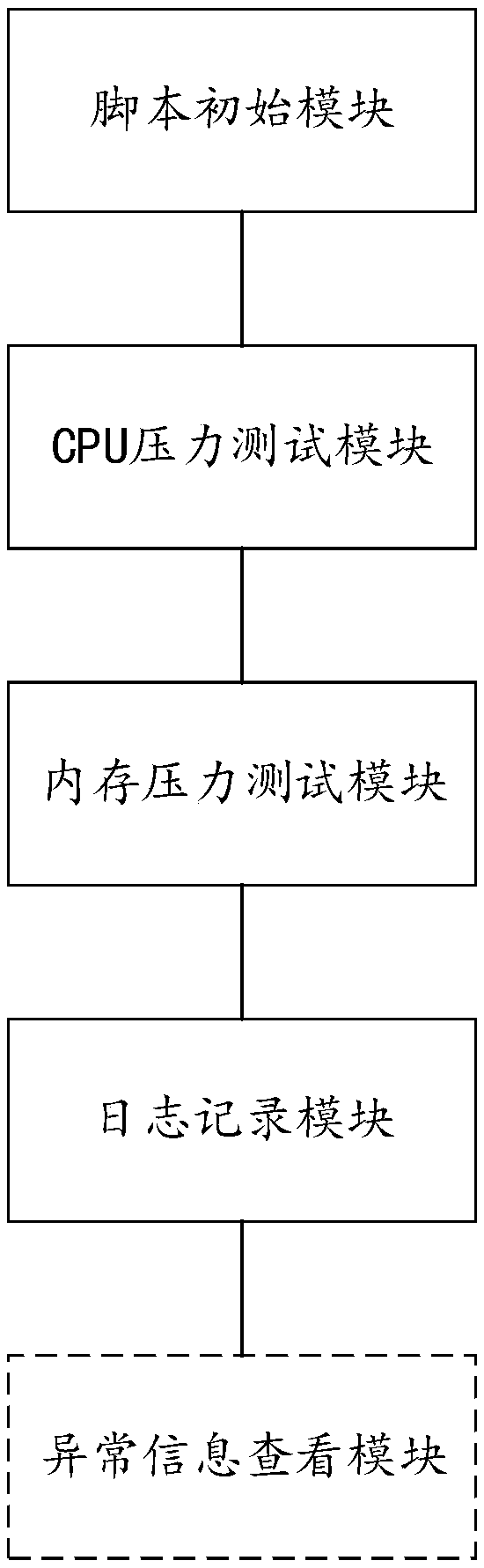

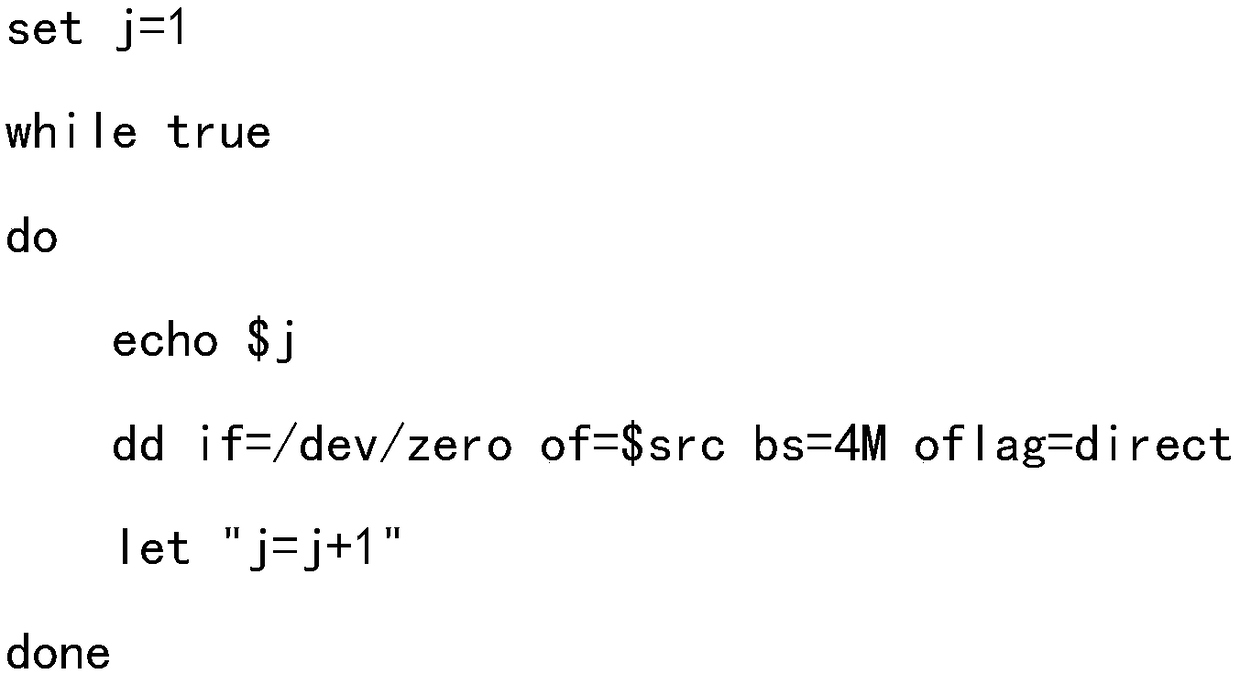

The invention relates to a pressure test method and a system of a NAS virtual machine system under an MCS system

InactiveCN109144669AImplement stress testingSolve the problem of low efficiency of fault locationSoftware simulation/interpretation/emulationAutomatic testingNull device

The invention provides a pressure testing method and a system of a NAS virtual machine system under an MCS system, comprising the following steps: S1, logging in a NAS virtual machine of each node, copying a script to a / tmp / directory, and endowing the script with corresponding authority; S2, copying the NAS virtual machine to a / tmp / directory; S2, the CPU obtaining the MCS resources and continuously cycle 0 writing to the / dev / null device; S3, continuously writing 0 to the src device; S4, if the virtual machine is restarted during the pressurization test, the relevant log being recorded. The invention can not only realize the pressure test of the NAS virtual machine system, at the same time, it can automatically record the NAS virtual machine abnormalities during the pressure process and output the abnormalities to relevant logs. The invention solves the problem of low fault location efficiency in the stress test of NAS virtual machine system in the prior art and greatly improves the fault location efficiency in the test process. The realization of the method makes it possible to test the stability of NAS virtual machine automatically.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

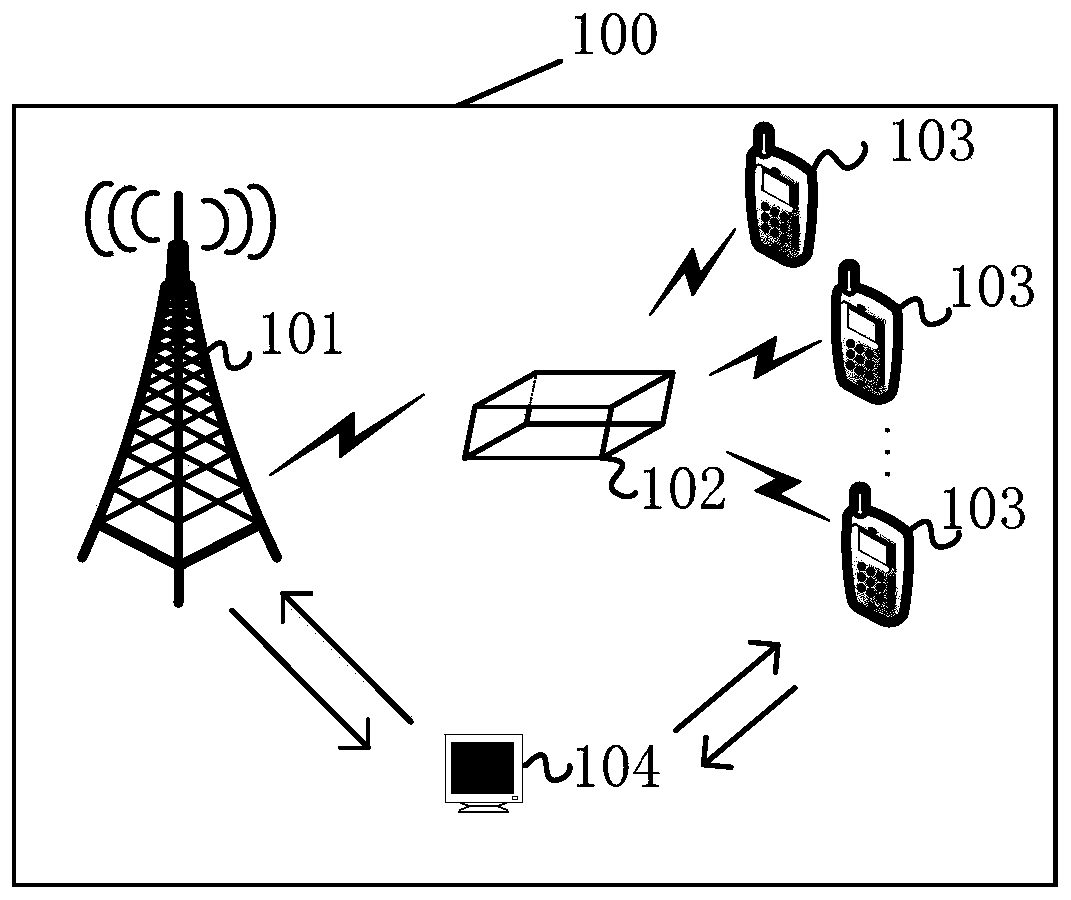

Terminal test method, terminal test device, test equipment and storage medium

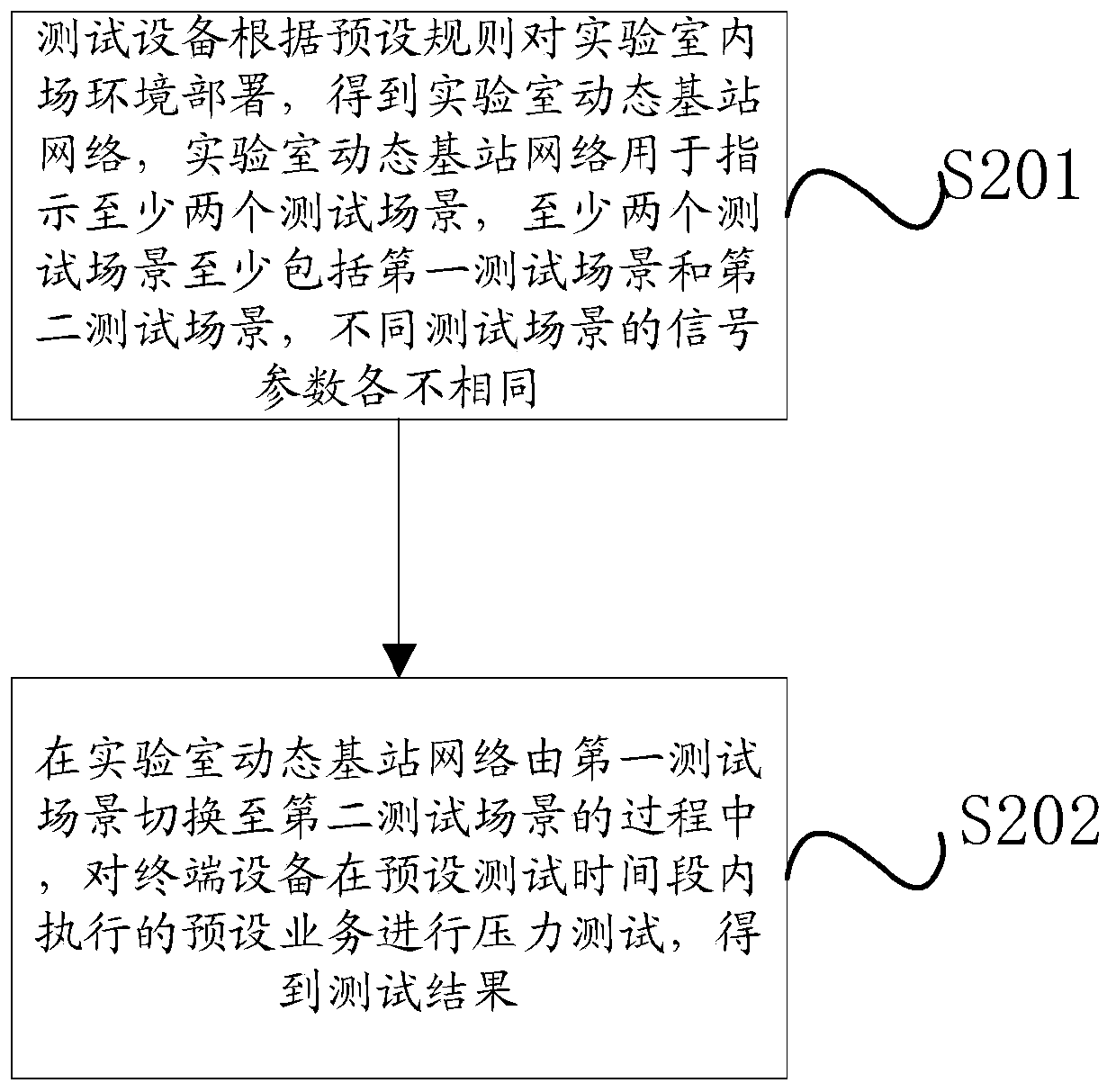

PendingCN111601331AImplement stress testingTransmission monitoringWireless communicationBlind zoneSimulation

The embodiment of the invention discloses a terminal test method, a terminal test device, test equipment and a storage medium. The method comprises the following steps: the test equipment deploys thelaboratory infield environment according to a preset rule to obtain laboratory dynamic base station networks, wherein the laboratory dynamic base station network is used for indicating at least two test scenes; wherein the at least two test scenes at least comprise a first test scene and a second test scene; signal parameters of different test scenes are different; in the process of switching thelaboratory dynamic base station network from the first test scene to the second test scene, the laboratory dynamic base station network is switched from the first test scene to the second test scene,the pressure test is performed on the preset service executed by the terminal equipment in the preset test time period to obtain the test result, and the pressure test of the terminal equipment in themotion scene with variable signals is realized by simulating the laboratory dynamic base station network by implementing the method, so that the blind area of the pressure test is covered.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

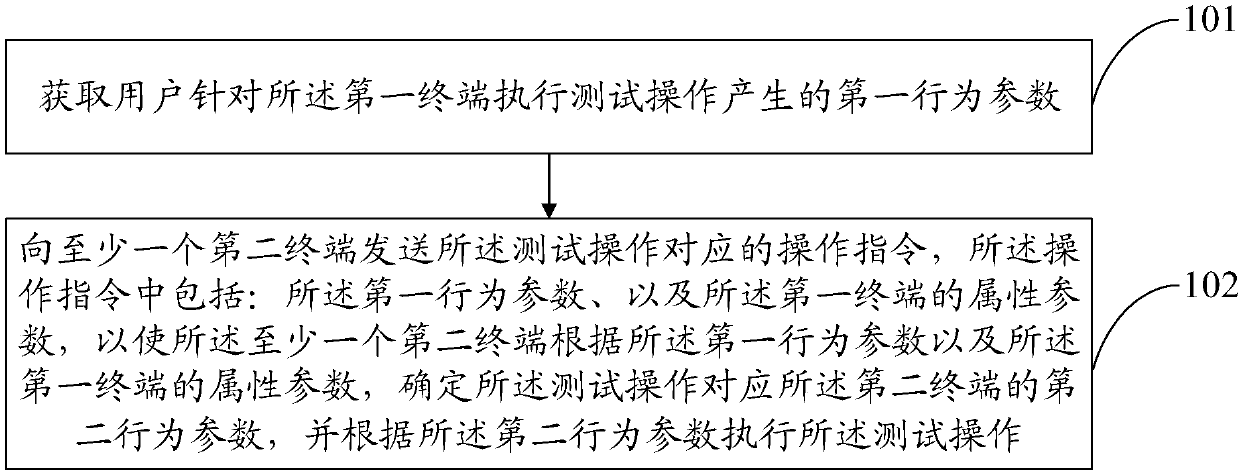

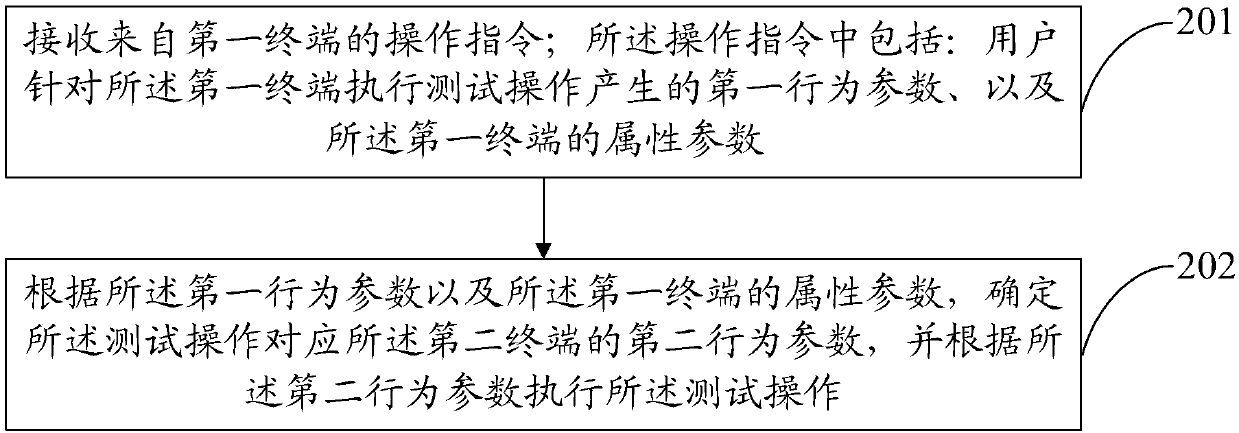

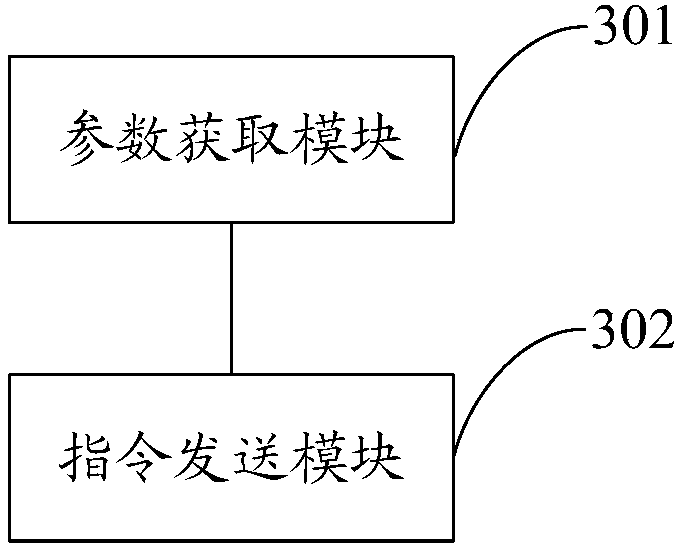

A test method and a test device

ActiveCN109922484AFully implement stress testingImplement stress testingWireless communicationLab test methodTest fixture

The embodiment of the invention provides a test method and a test device. The method comprises the following steps: acquiring a first behavior parameter generated by executing a test operation on a first terminal by a user; And sending an operation instruction corresponding to the test operation to at least one second terminal, wherein the operation instruction comprises: an operation instruction;and according to the first behavior parameter and the attribute parameter of the first terminal, enabling the at least one second terminal to determine a second behavior parameter of the second terminal corresponding to the test operation according to the first behavior parameter and the attribute parameter of the first terminal, and executing the test operation according to the second behavior parameter. The embodiment of the invention can improve the accuracy of the pressure test result of the base station and save the labor cost.

Owner:DATANG MOBILE COMM EQUIP CO LTD

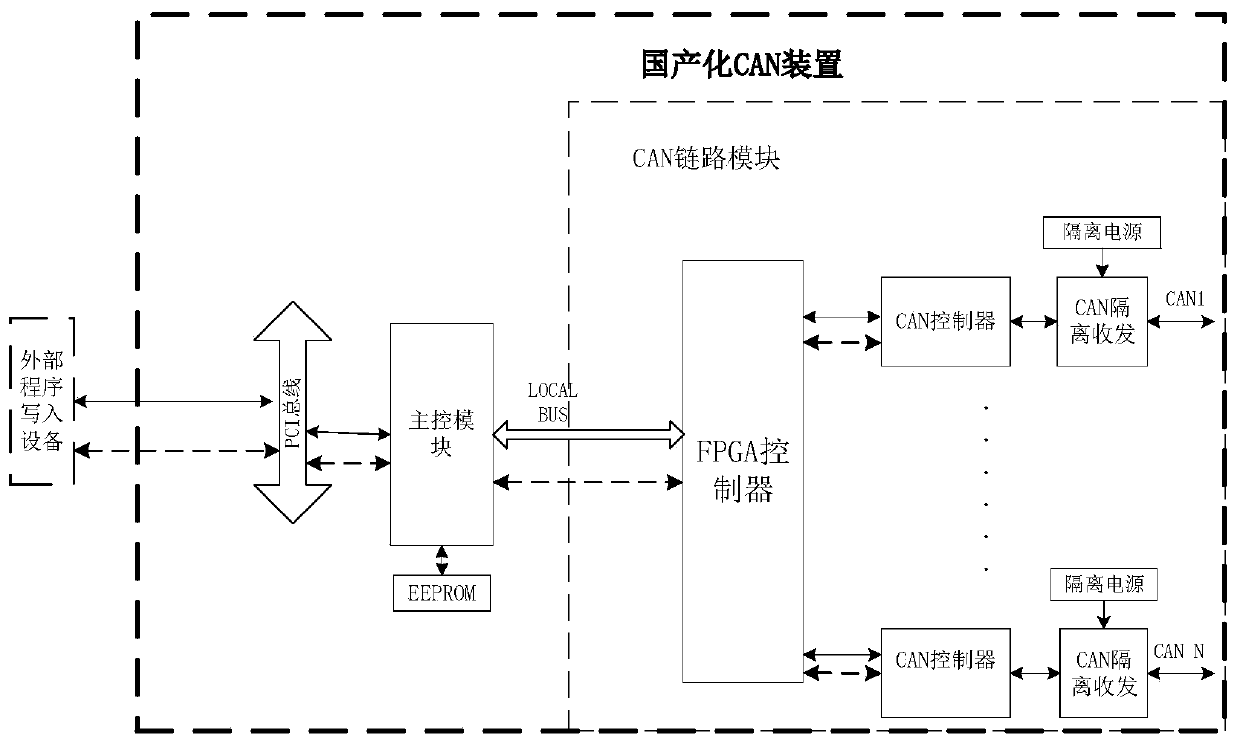

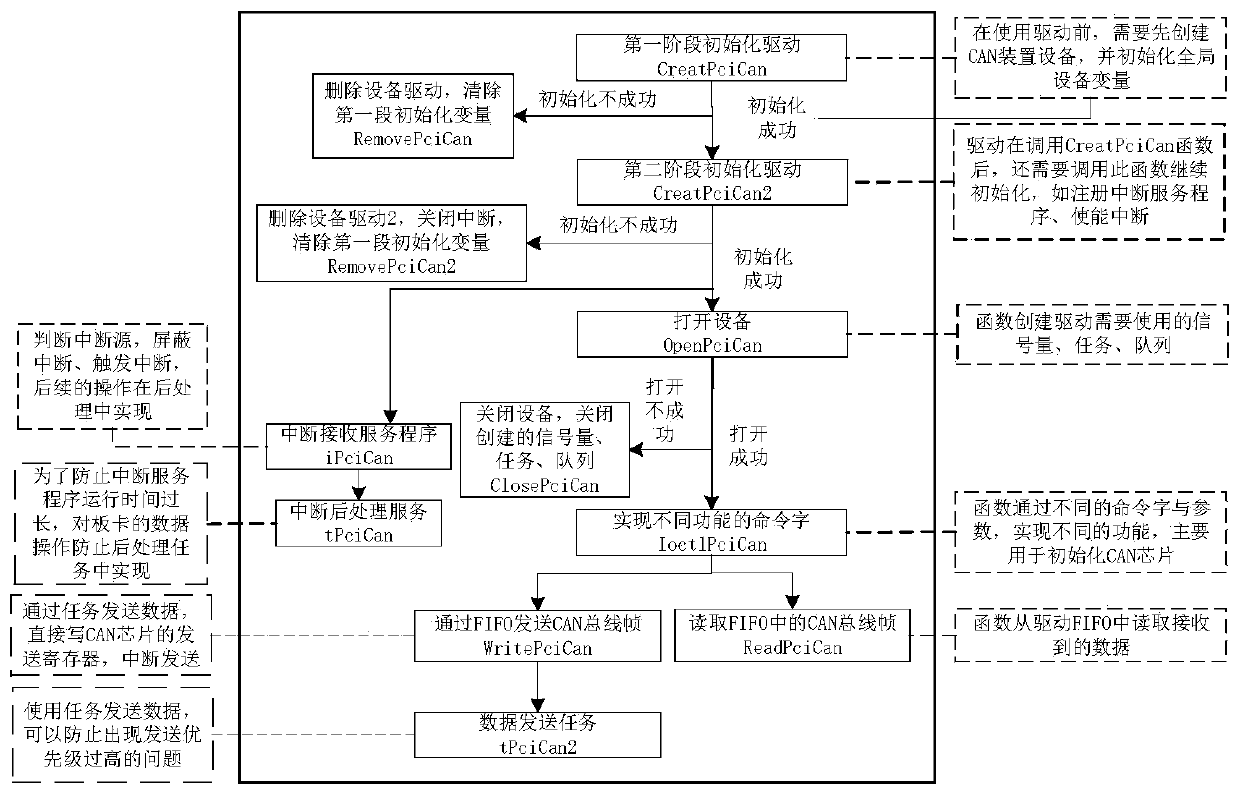

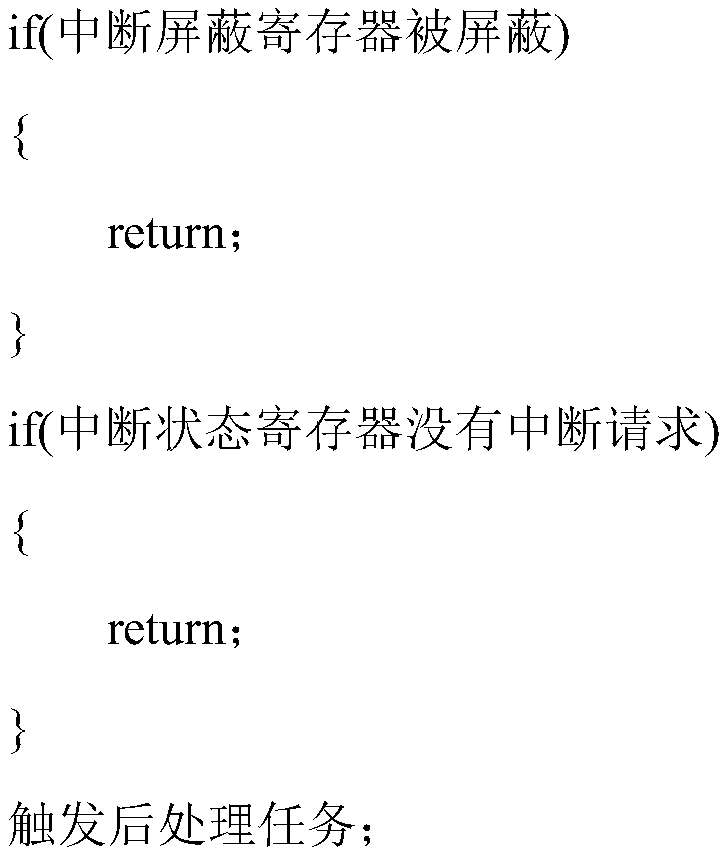

CAN equipment driving device and method based on PCI bus

ActiveCN110109849AEnsure the correct operation of the driverGuaranteed stabilityElectric digital data processingMessage queueInput control

The invention discloses a CAN equipment driving device and method based on a PCI bus. The device comprises a main control module, an FPGA module and a CAN link module which are sequentially connected;the main control module comprises a driving module, a switching equipment module, a control module and an interruption module; the driving module is used for externally inputting a first-stage instruction and a second-stage instruction to realize identification of equipment to be driven and setting of initialization parameters; the switch equipment module is used for opening or closing semaphore,a task, sending FIFO, receiving FIFO and a message queue of the CAN link module according to an externally input switch instruction; the control module is used for realizing a command word function,a reading function and a writing function operation on the CAN link module according to an externally input control instruction; and the interruption module is used for controlling the CAN link moduleto realize interruption operation on the to-be-driven equipment according to an interruption instruction input externally, thereby controlling the CAN link module to realize driving of the to-be-driven equipment.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

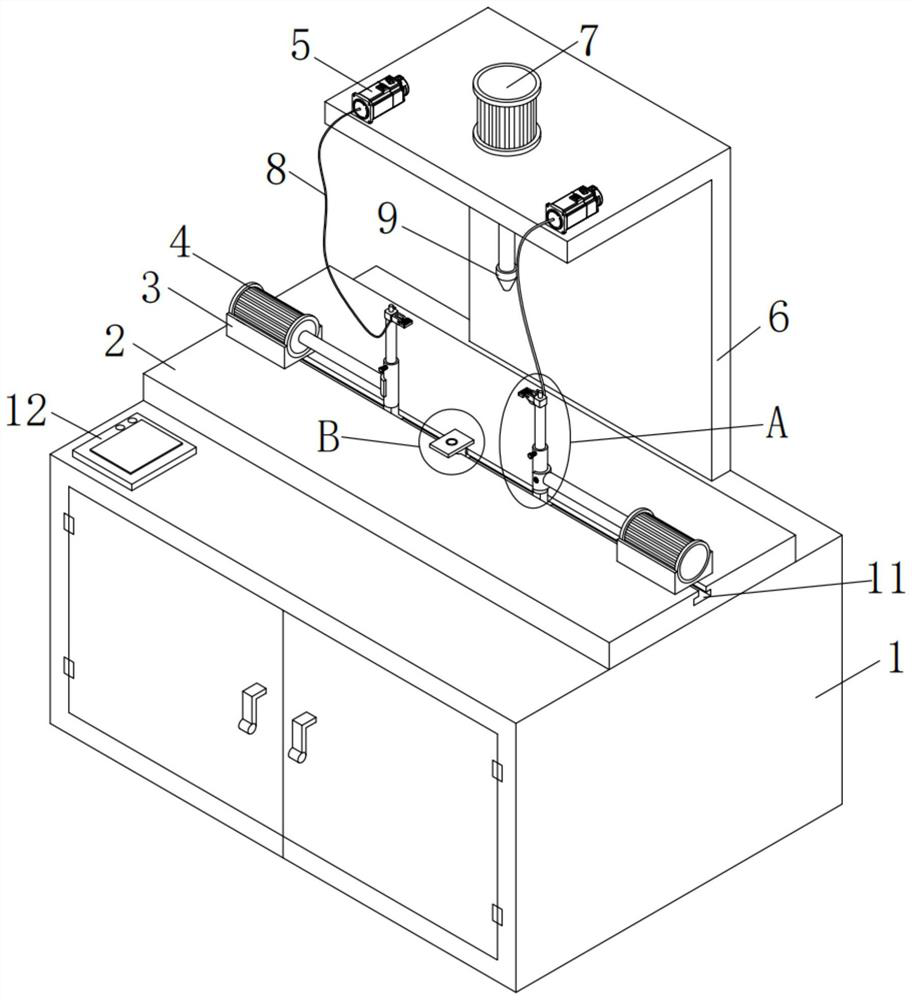

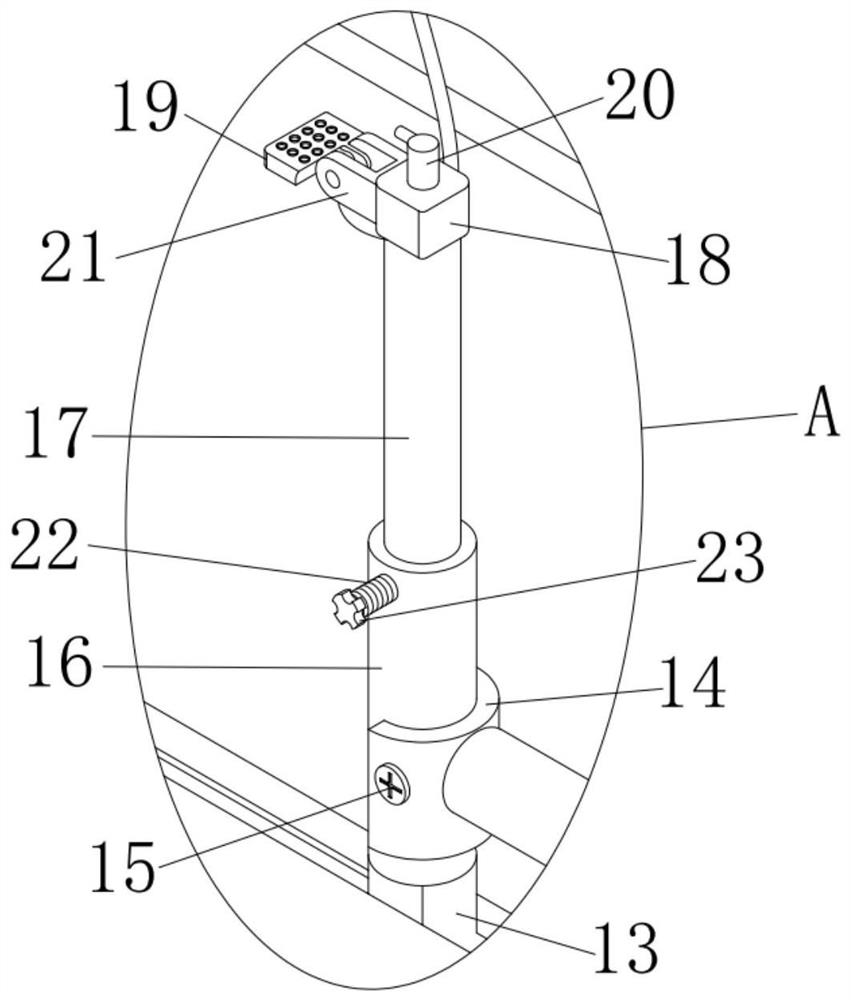

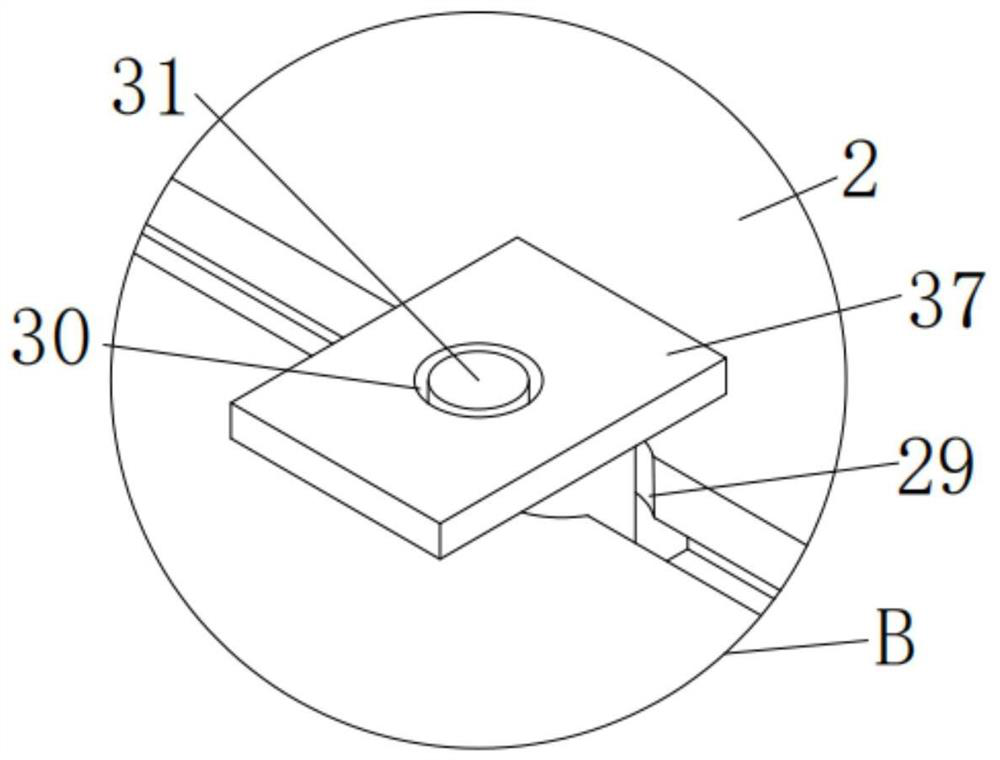

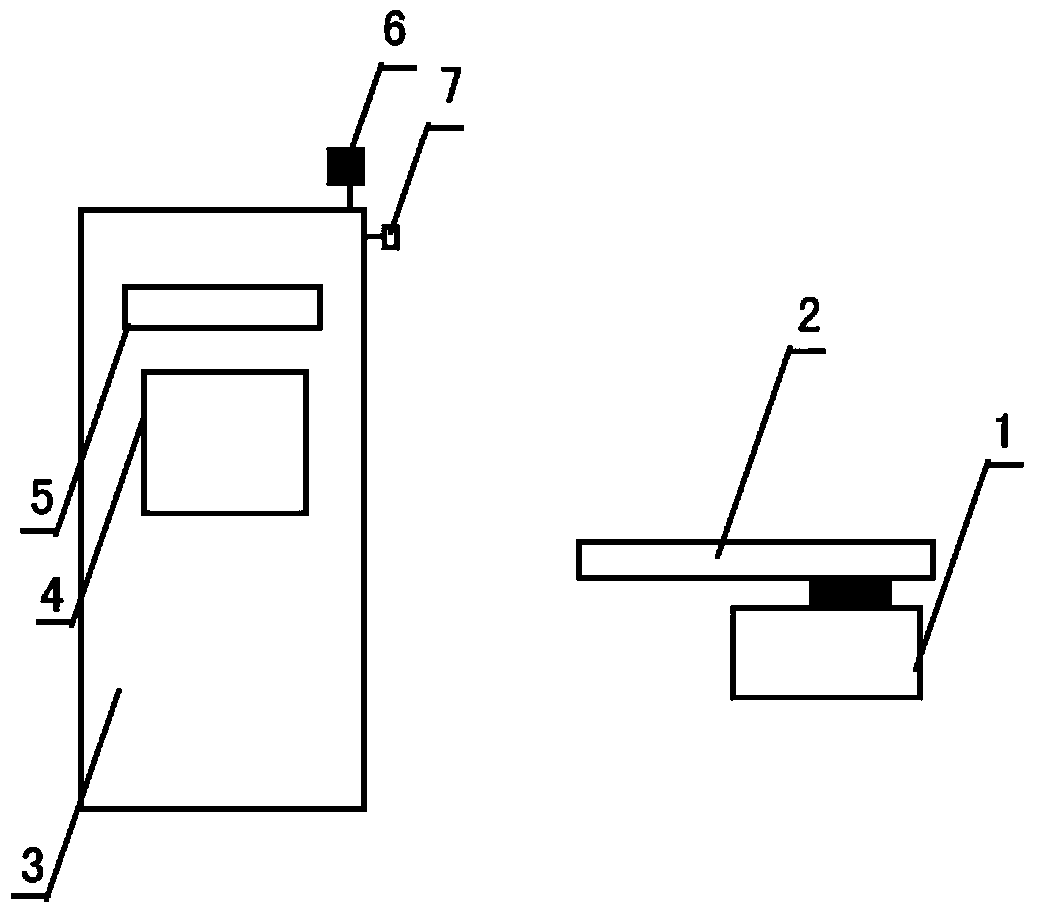

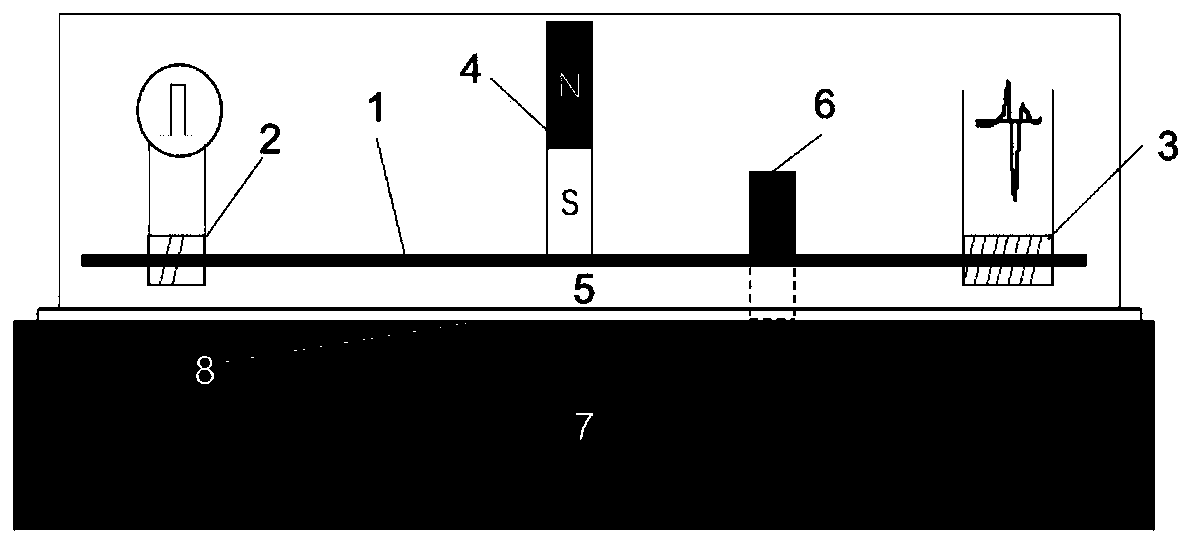

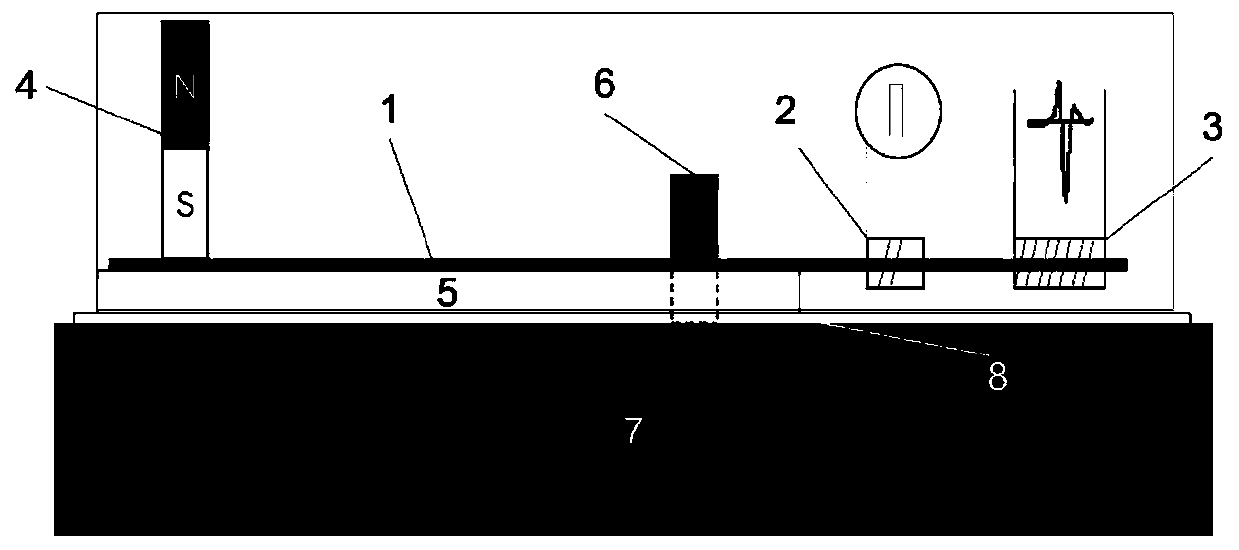

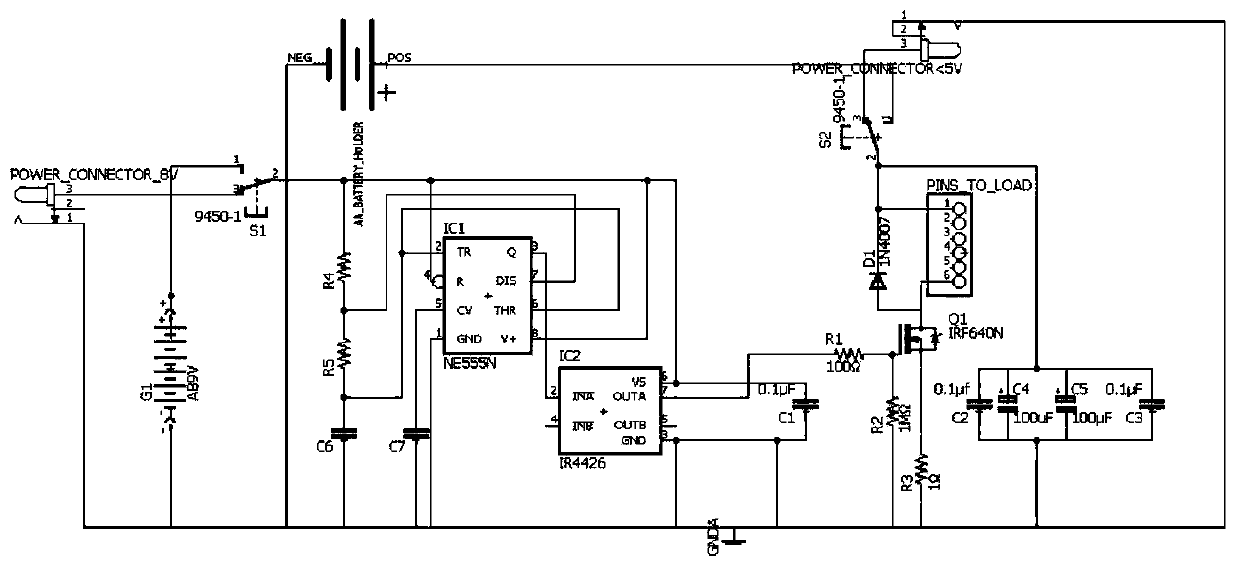

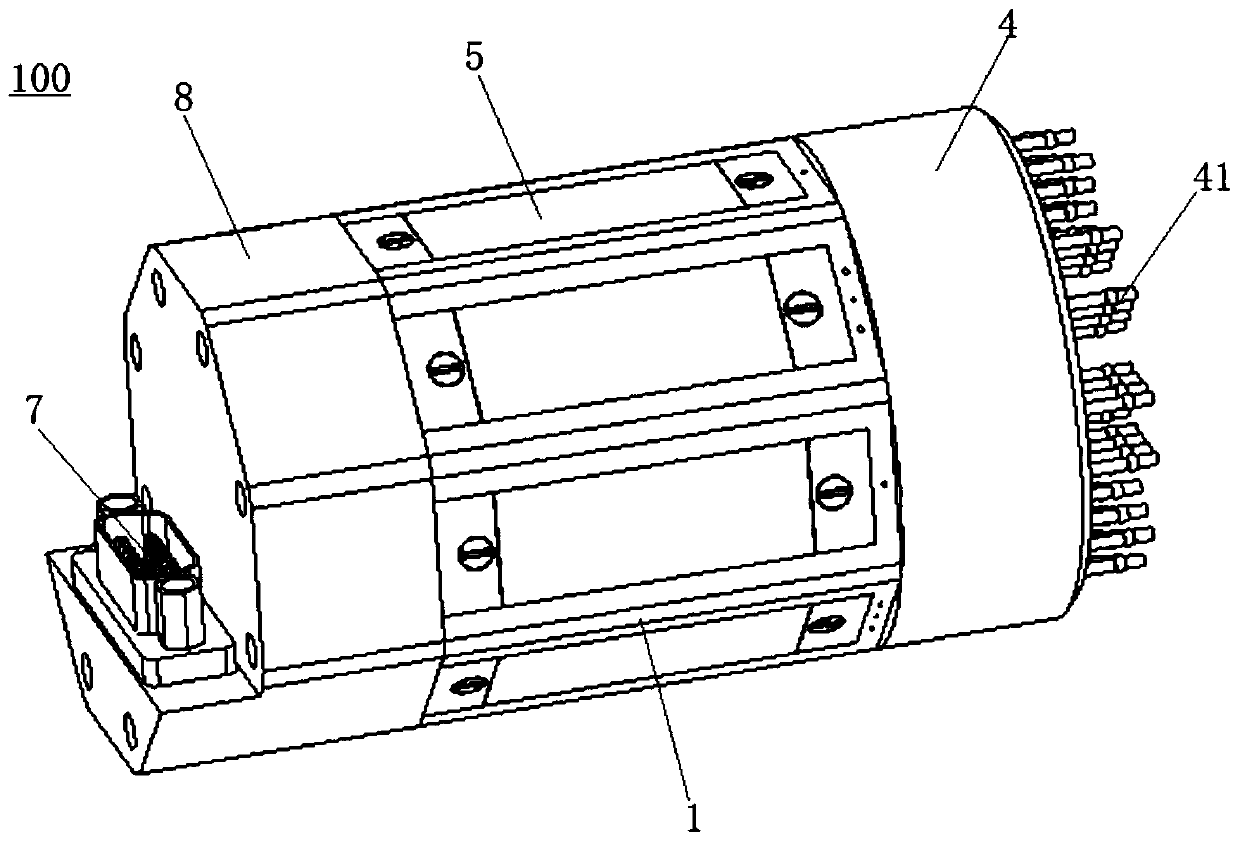

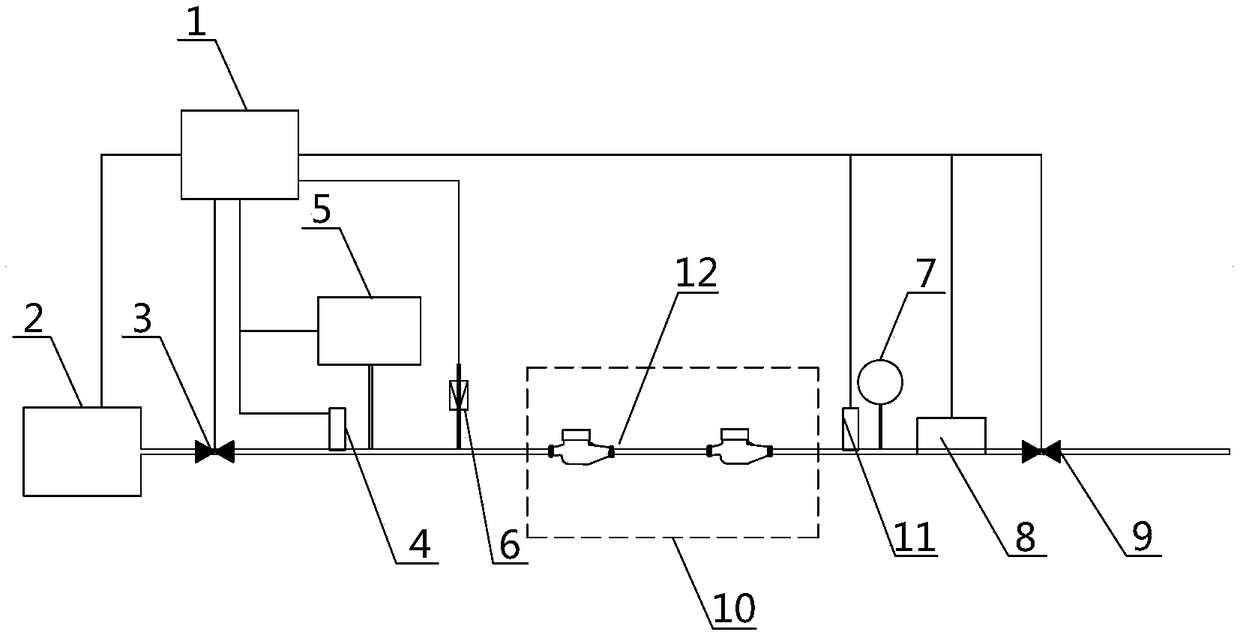

Device for testing complete machine pressure of high-pressure cleaning machine

InactiveCN103644993AStress testing is achieved preciselyImplement stress testingApparatus for force/torque/work measurementLiquid-crystal displayHigh pressure water

The invention relates to a device for testing complete machine pressure of a high-pressure cleaning machine. The device comprises a frame (1), wherein the frame (1) is provided with a spray gun (2) of the tested high-pressure cleaning machine, a pressure testing bench (3) is arranged in front of the frame (1), and a pressure testing area (4), a liquid crystal display device (5) and a prompting device (6) are arranged on the pressure testing bench (3). High-pressure water flow strikes the pressure testing area (4) during the test, relevant pressure test data is displayed on the liquid crystal display device (5), and the prompting device (6) gives out corresponding prompt data when the water pressure data exceeds the base standard. According to the device for testing the complete machine pressure of the high-pressure cleaning machine, a prompting mode of the prompting device is sound or lamp light display. A water collecting device is arranged below the pressure testing bench (3) so as to recycle water for testing. The device is further provided with a USB data port (7) to transmit relevant data analysis. The device provided by the invention can precisely realize testing of the complete machine pressure of the high-pressure cleaning machine, and can realize transmission and analysis of the data.

Owner:YINCHUAN BOJU IND PROD DESIGN

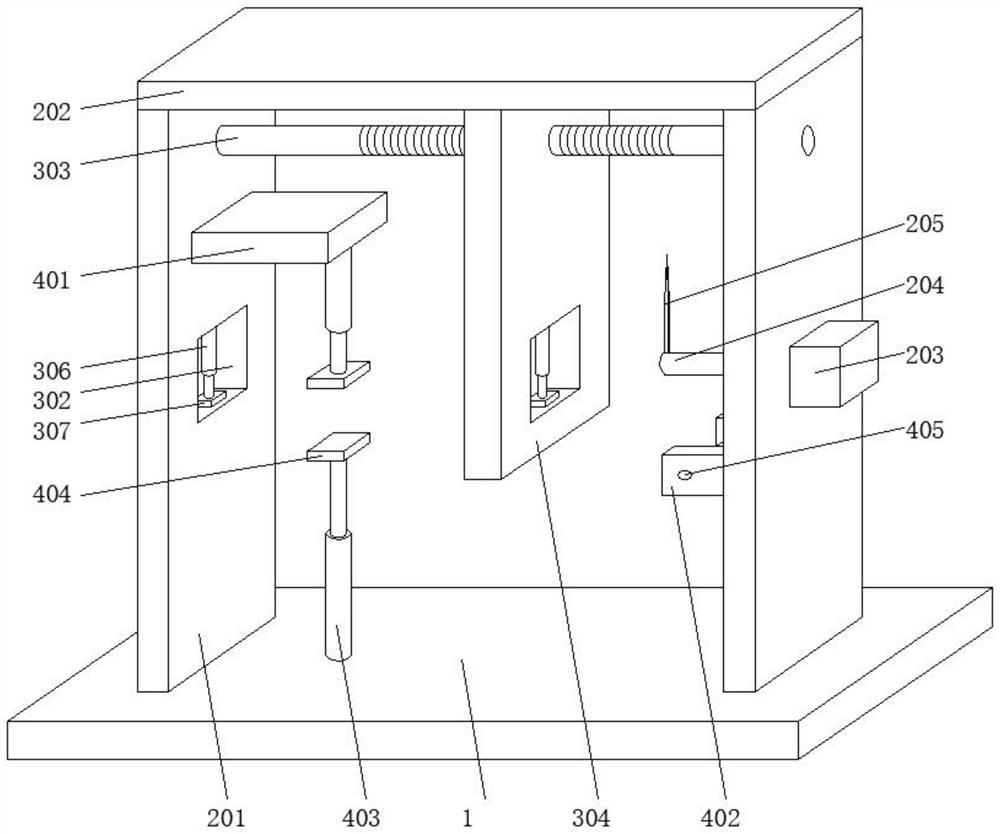

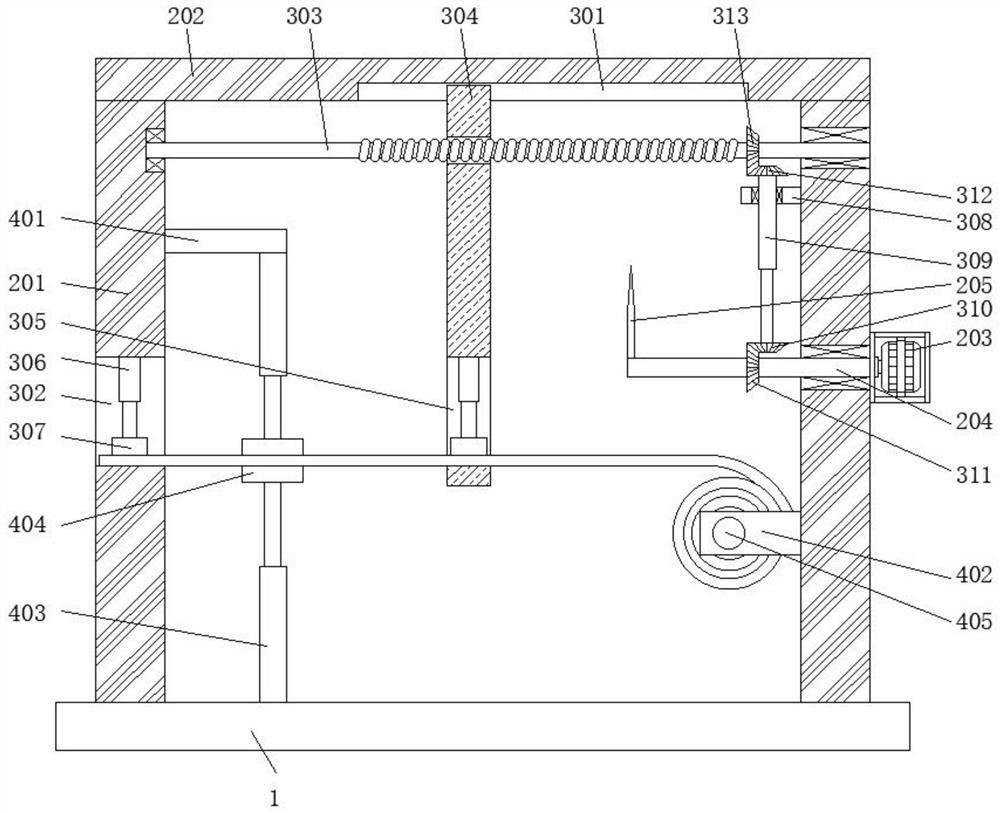

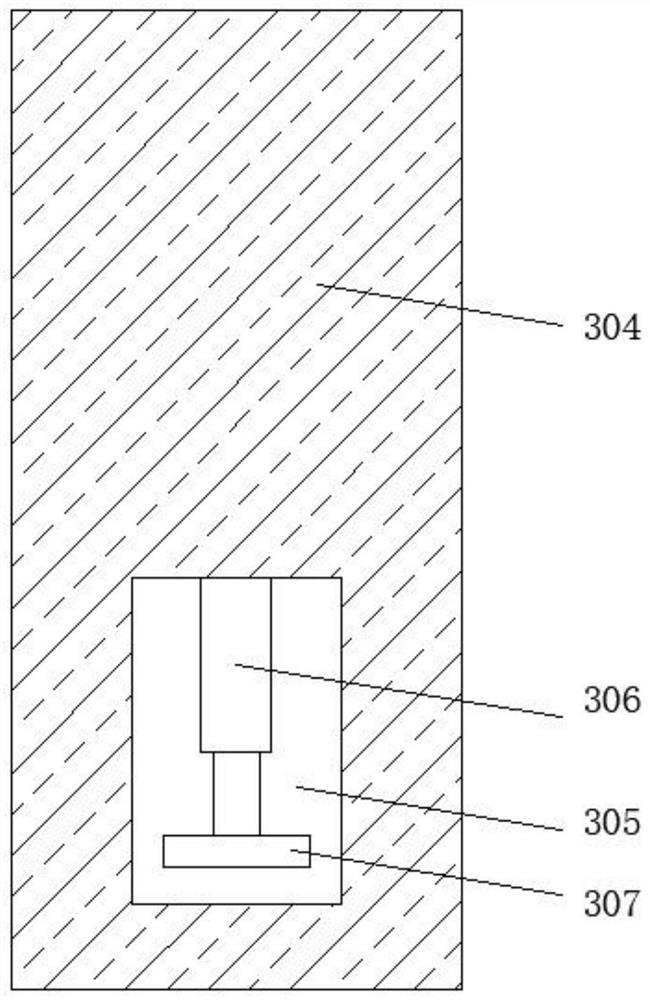

Wire testing machine with wire processing function

PendingCN113484151AAchieve reductionEasy to check functionMaterial strength using tensile/compressive forcesWire rodTensile testing

The invention relates to the technical field of wire rod testing machines, and particularly discloses a wire rod testing machine with a wire rod processing function, which comprises a base, a wire rod cutting mechanism, a tensile testing mechanism and a compression testing mechanism. The wire rod cutting mechanism is arranged at the top of the base, the wire rod cutting mechanism is used for processing wire rods, the wire rod cutting mechanism comprises supporting frames and a top plate, the supporting frames are symmetrically and fixedly connected to the top of the base, and the top plate is fixedly connected to the tops of the two supporting frames; and the tensile testing mechanism is arranged between the supporting frames and the top plate. According to the invention, the wire rod is wound on the winding roller, the two first hydraulic telescopic rods are used for driving the fixing plate to move downwards to fix and clamp the two ends of the wire rod, the motor is used for driving the cutting knife to rotate, cutting of the wire rod is achieved, later function detection of the wire rod is facilitated, the moving plate moves rightwards to drive the wire rod to stretch, and the tensile function test of the wire rod is achieved. And meanwhile, the wire processing function is added, and the practicability of the device is improved.

Owner:合肥吉顺新能源科技有限公司

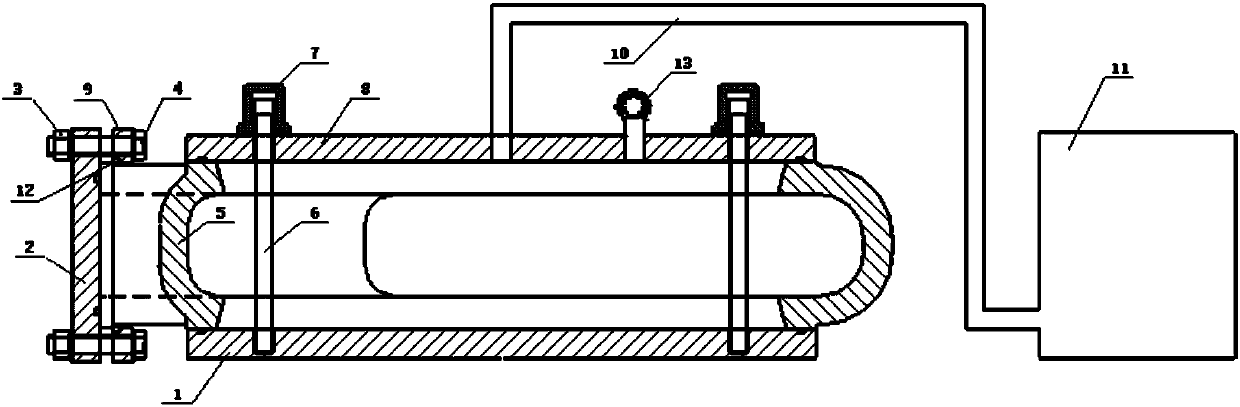

A pressure testing device for a sheath

InactiveCN107702995AControl blank qualityImplement stress testingMaterial strength using tensile/compressive forcesMechanical engineeringBooster pump

The invention relates to a pressure testing device for a sheath, and belongs to the field of fluid machinery. The device includes a bottom plate, a side plate, a top plate, a split-half inner ring, aside-plate clamping ring, a booster pump and a pressure boosting pipe. The top plate and the bottom plate are disposed at upper and lower end ports of the sheath. The top and bottom plates are clampedtightly and sealed through studs. The side plate is mounted outside a lateral outlet of the sheath. The rear end of a port connection stage of the lateral outlet of the sheath is sleeved with the split-half inner ring and the side-plate clamping ring. The side-plate clamping ring and the side plate are fastened through screws and nuts. The device achieves tests on actual pressure of a separated sheath component, and can effectively control blank quality of the sheath. Complete machine assembling before pressure testing is not needed, thus increasing the pressure testing efficiency and reducing component retention time.

Owner:XIANGYANG WU ER WU PUMP IND

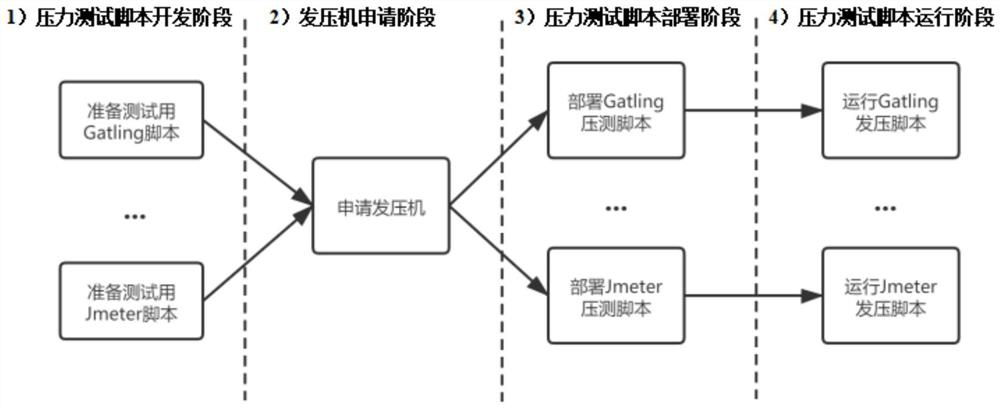

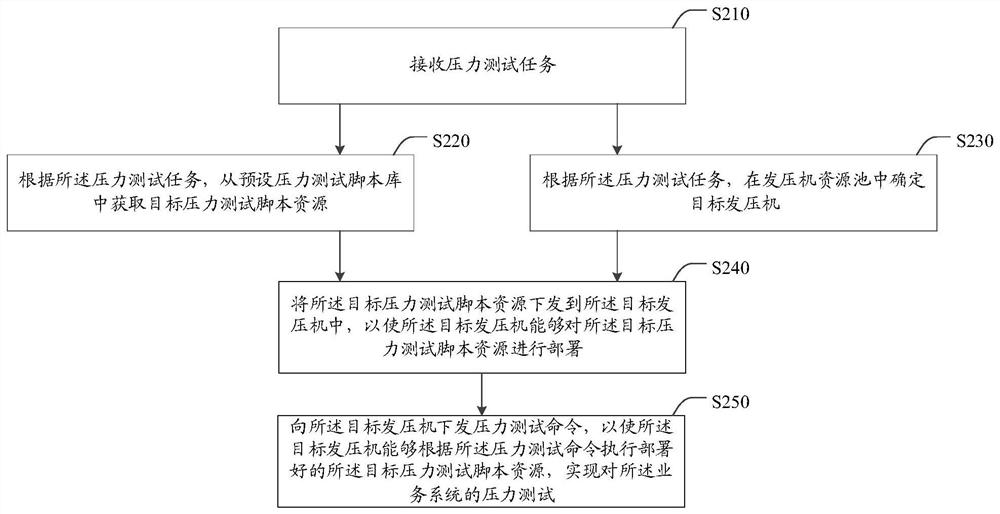

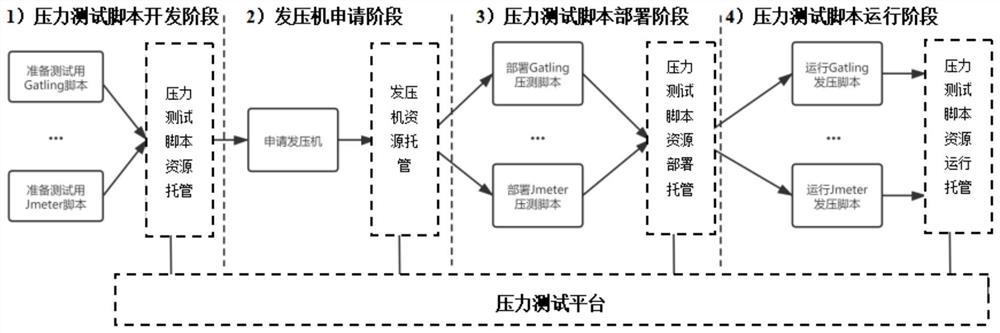

Business system pressure test method and device and pressure test system

PendingCN114691476AImplement stress testingStress testing method, which can be implemented by individual deploymentSoftware testing/debuggingService systemSystem pressure

The invention discloses a business system pressure test method, device and system, and the method is executed by a pressure test server, and comprises the steps: receiving a pressure test task; obtaining a target pressure test script resource from a preset pressure test script library according to the pressure test task; determining a target pressure generator in a pressure generator resource pool according to the pressure test task; issuing the target pressure test script resource to the target pressure generator, so that the target pressure generator can deploy the target pressure test script resource; and a pressure test command is issued to the target pressure generator, so that the target pressure generator can execute the deployed target pressure test script resource according to the pressure test command, and pressure test on the service system is realized. According to the method and the device, the development of the pressure test script, the application of the pressure generator resource, the deployment of the pressure test script resource and the trusteeship of the whole process of the operation of the pressure test script resource are realized, the pressure test process is solidified, and the pressure test efficiency is improved.

Owner:NETSUNION CLEARING CORP

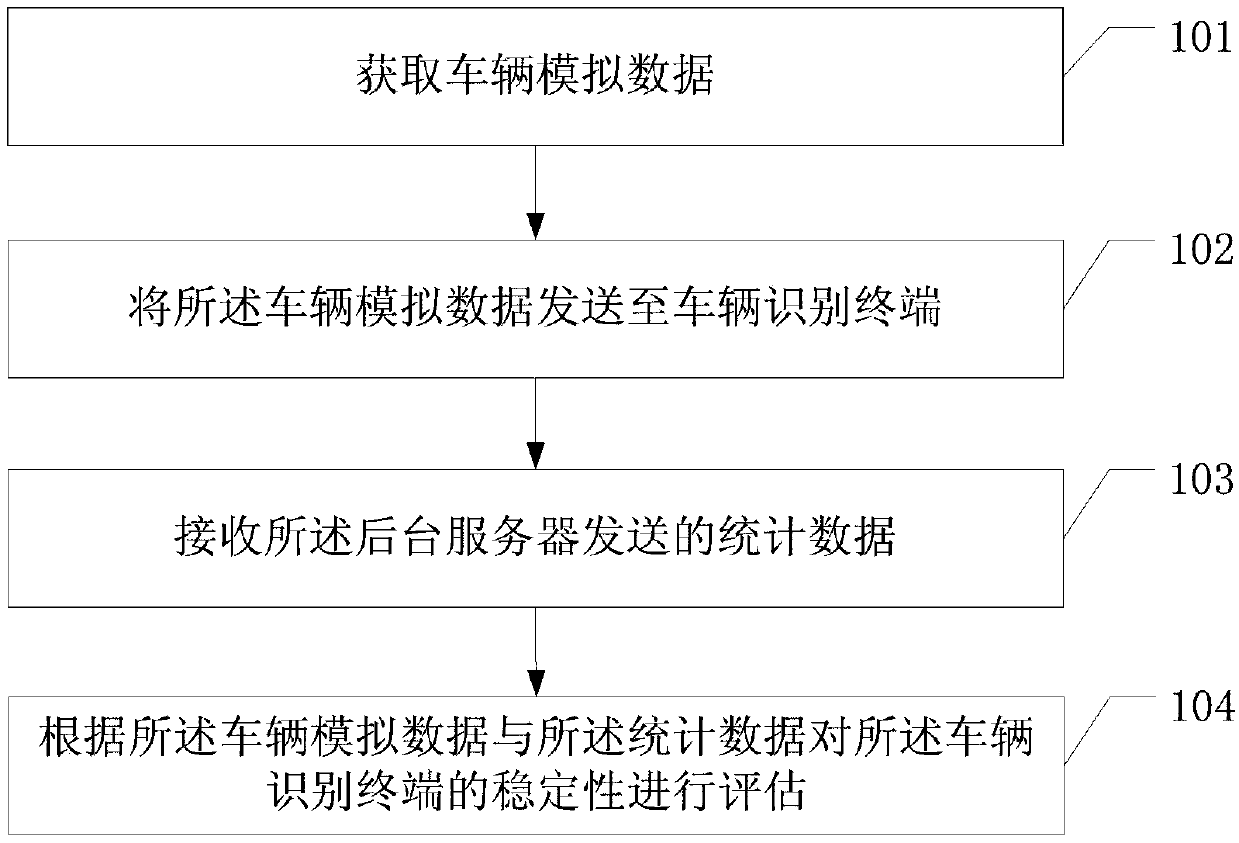

Vehicle data processing method and related equipment

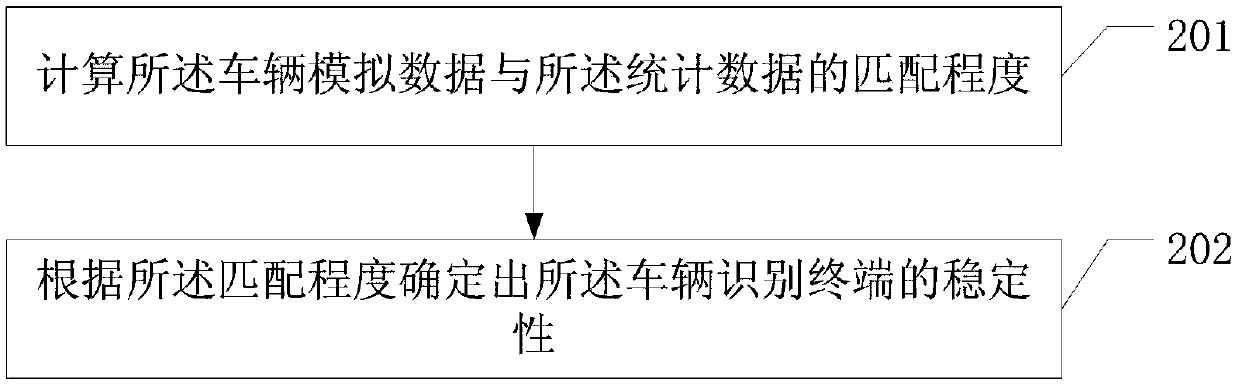

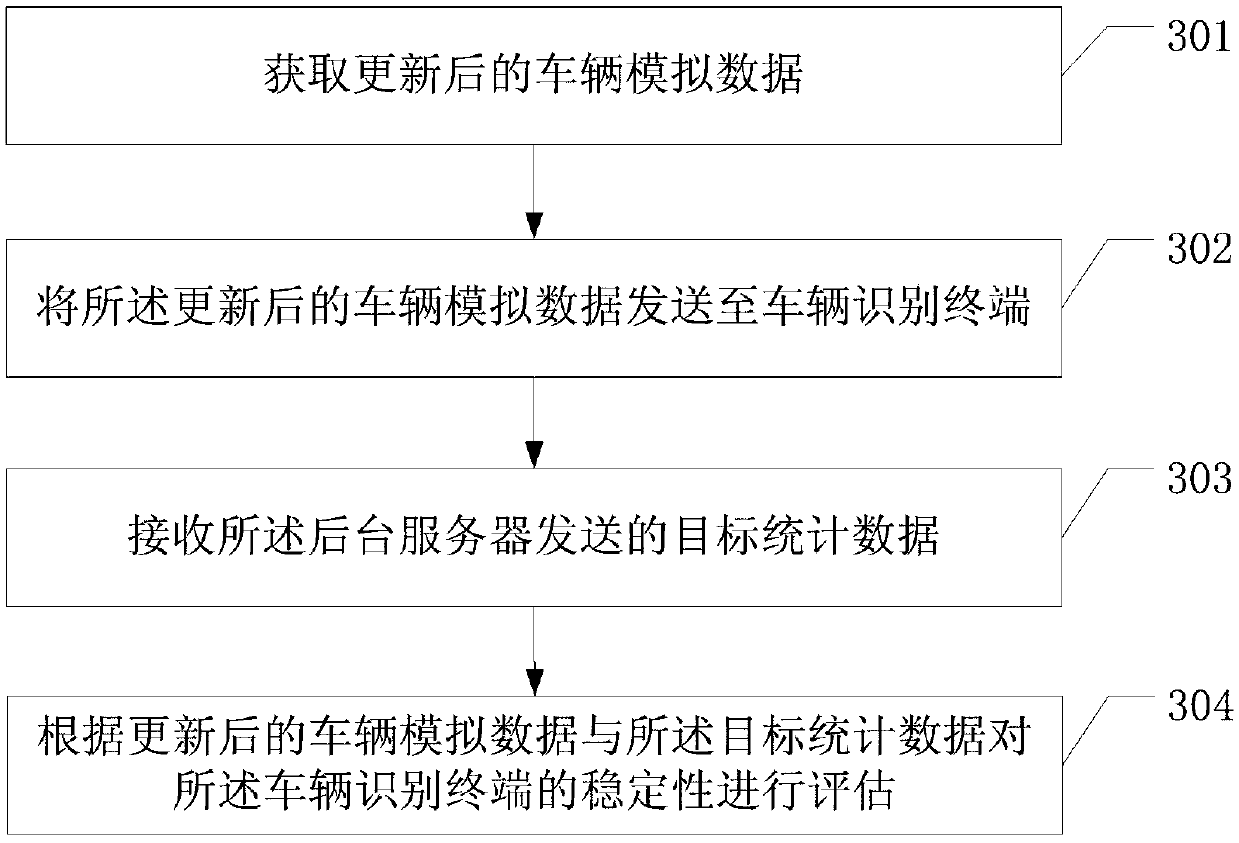

InactiveCN109658706AAchieve stabilityImplement stress testingRoad vehicles traffic controlHardware monitoringComputer terminalComputer science

An embodiment of the invention discloses a vehicle data processing method and related equipment, wherein the method and the equipment are used for realizing pressure testing on a vehicle identifying terminal. The vehicle data processing method comprises the steps of acquiring vehicle analog data; transmitting the vehicle analog data to the vehicle identifying terminal so that the vehicle identifying terminal identifies the vehicle analog data and obtains processing data, and transmitting the processing data to a background server; receiving statistics data which are transmitted from the background server, wherein the statistics data are obtained performing statistics by the background server according to the processing data; and evaluating stability of the vehicle identifying terminal according to the vehicle analog data and the statistics data, wherein the stability of the vehicle identifying terminal is evaluated according to the vehicle analog data and the statistics data. Namely evaluation to the stability of the vehicle identifying terminal is realized through acquiring the vehicle analog data, thereby realizing pressure testing to the vehicle identifying terminal.

Owner:SHENZHEN JIESHUN SCI & TECH IND

Network server pressure testing method and system

ActiveCN101184001BImplement stress testingAvoid early exposureData switching networksTest requirementsClient-side

The invention discloses a test method for the workload test of the network service, comprising the following steps: A: set a plurality of virtual client sides; B: establish the links between the server and each virtual client side; C: establish the instruction reading thread and the circulation thread of the virtual client sides; D: each virtual client side stores the client side data behaviorallyrelated with the virtual client sides of the required test; E: the circulation thread of the virtual client sides traverses each virtual client side, receives the protocol package of the server respectively; F: judge whether the protocol package is behaviorally related with the virtual client sides of the required test, if yes, execute the step G, or end; G: analyze the content of the protocol package, update the internal status of the virtual client sides, read the instruction of the virtual client side instruction sequence, execute the corresponding operation. The invention provides a workload test method and a system of the network service, which are used to meet the test requirement of the network service, and avoids the exposure of the network product in advance.

Owner:BEIJING KINGSOFT SOFTWARE +1

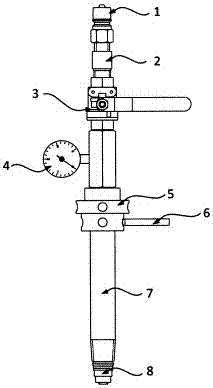

Hydraulic testing gun

InactiveCN107449669AFlexible useThere is no problem of occupying spaceMaterial strength using tensile/compressive forcesHand heldScrew head

The invention provides a hydraulic testing gun, comprising a gun seat, wherein the front part of the gun seat has a hand-held rod; the front end of the hand-held rod has a multistage screw head; the tail end of the gun seat is connected with a pressure gauge; the rear part of the pressure gauge is connected with a switch valve; the rear end of the switch valve is provided with a quick connector; and the quick connector is connected with a booster pump. The movable pressure-resistant testing gun with the hand-held rod does not need calibration and moving of a container and is flexible to use; meanwhile, the gun does not occupy great space, and can realize pressure testing as long as different threads of the multistage screw head are switched and used for different containers.

Owner:HUANGSHI XIANDA ELECTRIC CO LTD

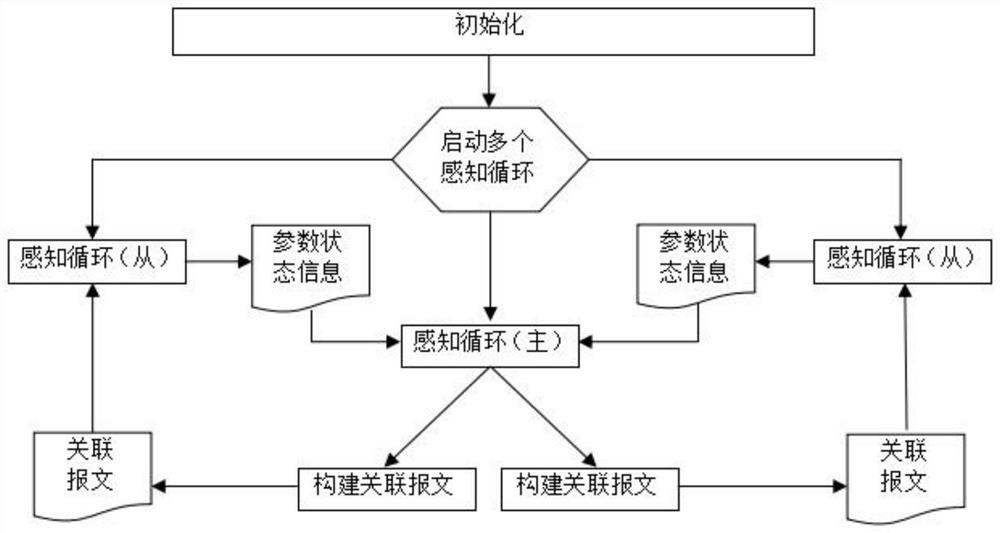

Method, device and system for stress testing

ActiveCN106506255BReduce the chance of becoming a bottleneckSolve the problem of insufficient upper limit of expansion capacityData switching networksSystem under testComputer science

The invention discloses a pressure test method, a pressure test device and a pressure test system, used for improving scale and efficiency of a pressure test. The method is applied to a distributed pressure test system which comprises a main node scheduler and at least one main node, wherein each main node corresponds to at least one slave node. The method comprises the following steps: the main node scheduler starts each corresponding main node; for each main node, when the main node is started is detected, a pressure test start command is sent to the main node, so that the main node starts each corresponding slave node to perform the pressure test on a system under test, and acquires pressure test statistical information; and the corresponding pressure test statistical information transmitted by each main node is received, and summary statistics is performed, and thus a test result of the pressure test is acquired.

Owner:MICRO DREAM TECHTRONIC NETWORK TECH CHINACO

A real estate collateral risk control method, system and storage medium

ActiveCN106952159BImplement stress testingRealize risk warningFinanceRisk ControlOperations research

The present invention establishes an intelligent valuation algorithm system on the basis of collateral big data. The valuation process adopts a dual-network design. The first network is used to judge the most suitable evaluation algorithm for the collateral and increase the weight of the algorithm's valuation; the second network is used to collect user feedback information, whether it is correct valuation or biased On the one hand, the computer automatically analyzes and records, on the other hand, human participation helps the computer to correct the deviation or error, similar to a deviation or error memory stick, all of which are fed back to the first network. The two networks are constantly running in a loop, learning from the right and learning from the wrong. Over time, experience will be formed and continuous improvement. It can be concluded that the accuracy rate will become higher and higher, so as to realize automatic and accurate valuation of collateral in batches, and in the process of accurate valuation Based on risk analysis.

Owner:重庆汇集源科技有限公司

MDL-based nondestructive testing device for local stress distribution of ferromagnetic material

ActiveCN110824390AIncreased sensitivityImplement stress testingMagnetic field measurement using permanent magnetsMaterial magnetic variablesFerroicsCondensed matter physics

The invention discloses an MDL-based nondestructive testing device for local stress distribution of a ferromagnetic material. The detection device comprises an MDL with a uniform cross section, an excitation coil, a detection coil, a permanent magnet, a supporting piece and an ultrasonic echo detector; the MDL is arranged horizontally over the detected ferromagnetic material; the excitation coil and the detection coil are wound around the MDL, and distance between the excitation coil and the detection coil is avoid interference between excitation signals of the excitation coil and detection signals of the detection coil; the permanent magnet is fixed on the upper surface of the MDL; the supporting piece is arranged between the MDL and the detected ferromagnetic material to support the MDLand the permanent magnet; and the ultrasonic echo detector is attached to the detected ferromagnetic material via a preset through hole in the supporting piece so as to detect the thickness of the detected ferromagnetic material. Thus, rapid detection of local or continuous area(s) can be realized, and high precision and high sensitivity are ensured.

Owner:成都航大新材料有限公司

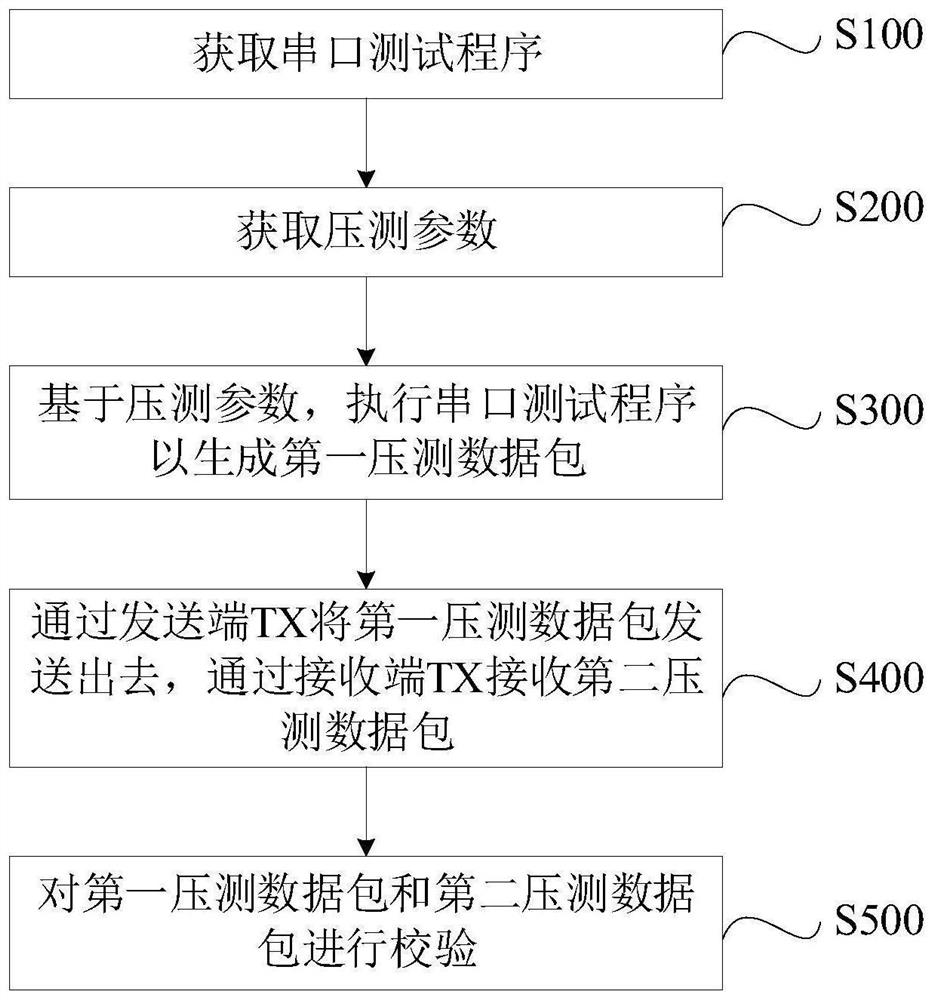

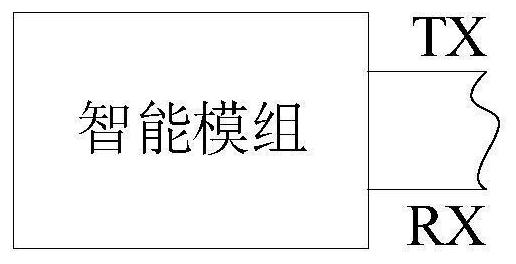

Serial port test method, intelligent module and storage medium

PendingCN113568793AImplement stress testingFlexible test scenariosHardware monitoringFunctional testingData packTest scene

The invention discloses a serial port testing method, an intelligent module and a storage medium. The serial port test method comprises the following steps: acquiring a serial port test program; obtaining pressure measurement parameters; based on the pressure measurement parameters, executing a serial port test program to generate a first pressure measurement data packet; sending out the first pressure measurement data packet through the sending end TX, and receiving the second pressure measurement data packet through the receiving end TX; and verifying the first pressure measurement data packet and the second pressure measurement data packet. According to the application, the sending end TX and the receiving end RX of the intelligent module are short-circuited, so that the pressure test of the serial port is realized, and external equipment is not needed. Moreover, the user can configure the pressure measurement parameters according to the actual scene, and the intelligent module carries out the serial port test according to the pressure measurement parameters configured by the user, so the test scene is more flexible.

Owner:XI AN FIBOCOM WIRELESS SOFTWARE INC

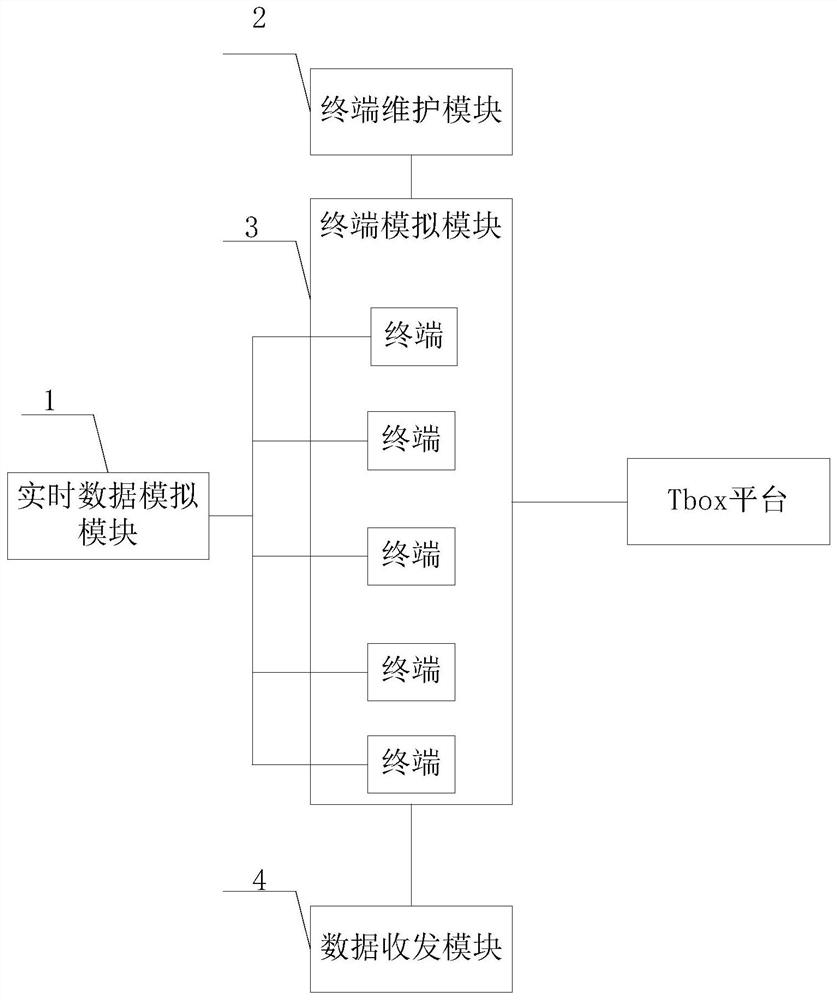

Performance verification system based on Tbox new energy automobile platform

InactiveCN112600700AEffective stress testImplement stress testingData switching networksData simulationVehicle frame

The invention discloses a performance verification system based on a Tbox new energy automobile platform, and relates to the technical field of Tbox performance verification of new energy automobiles.The problem that an existing new energy automobile testing platform cannot achieve multi-link simultaneous testing is solved. The method comprises the following steps: configuring information in a configuration file of a terminal simulation module, simulating one or n pieces of terminal equipment, marking frame numbers of the terminal equipment, establishing connection between the terminal and aTbox automobile platform, and deleting the terminal from a system if the connection is unsuccessful; enabling the maintenance terminal module to record the number of times that each terminal sends information to the Tbox automobile platform, and when any terminal fails to send information for three times, disconnecting the link to reestablish connection; enabling the real-time data simulation module to simulate real-time data of each terminal according to a 32960 protocol and send the simulated data to each terminal in the terminal simulation module in real time; and enabling the data transceiving module to control each simulated terminal in the system to circularly send data to the Tbox automobile platform. The system is suitable for performance verification of the Tbox platform.

Owner:AEROSPACE HI TECH HLDG GROUP

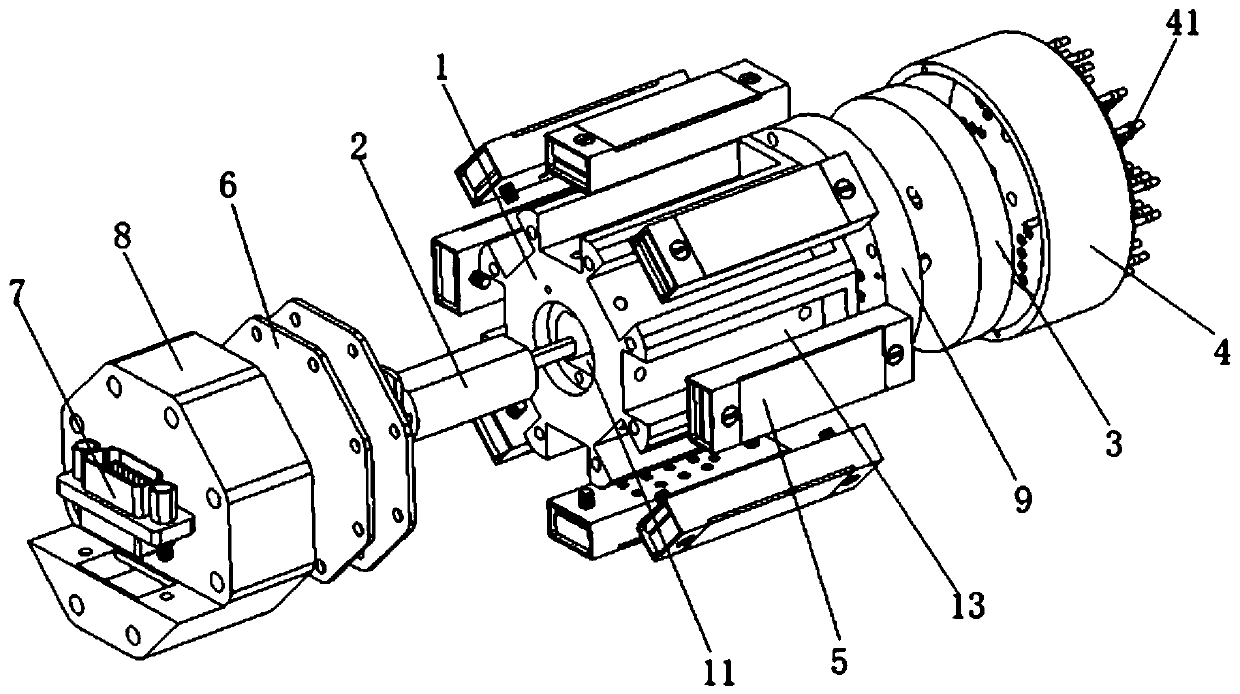

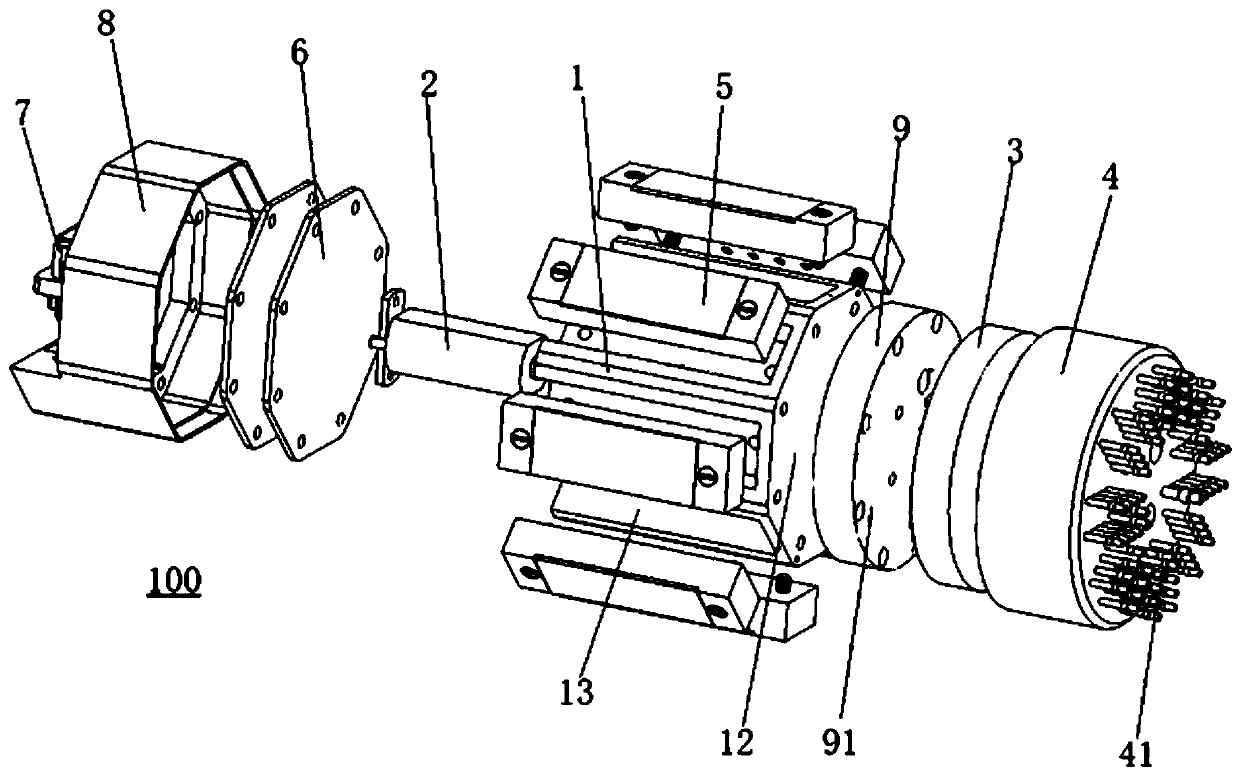

Rotary sliding disc type pressure electronic scanning valve

PendingCN111426424ASmall sizeImprove reliabilityFluid pressure measurementEngineeringMechanical engineering

The invention discloses a rotary sliding disc type pressure electronic scanning valve. The rotary sliding disc type pressure electronic scanning valve comprises an installation support internally provided with a hollow cavity, a rotary driving piece arranged in the hollow cavity, a rotary disc driven by the rotary driving piece to be switched between a first position state and a second position state in a rotary mode, a front end cover wrapping the rotary disc, and a plurality of pressure sensor assemblies annularly embedded in the installation support. A plurality of first air guide needle tubes and second air guide needle tubes are arranged on the front end cover; first sets of channels communicating with the pressure sensor assemblies in a one-to-one correspondence mode are arranged inthe installation support, and second sets of channels for communicating the first air guide needle tubes with the first sets of channels in a one-to-one correspondence mode and third sets of channelsfor communicating all the first sets of channels and communicating with the second air guide needle tubes are arranged in the rotary disc. Thus, automatic switching between a pressure detection stateand a sensor calibration state can be realized, online automatic calibration is realized, and the accuracy and reliability of pressure detection are greatly improved.

Owner:昆山御宾电子科技有限公司

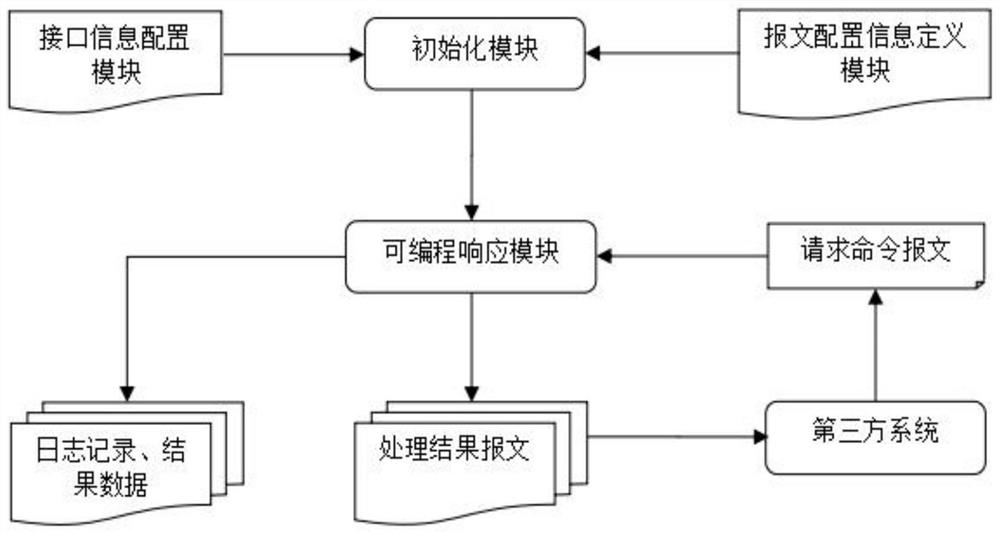

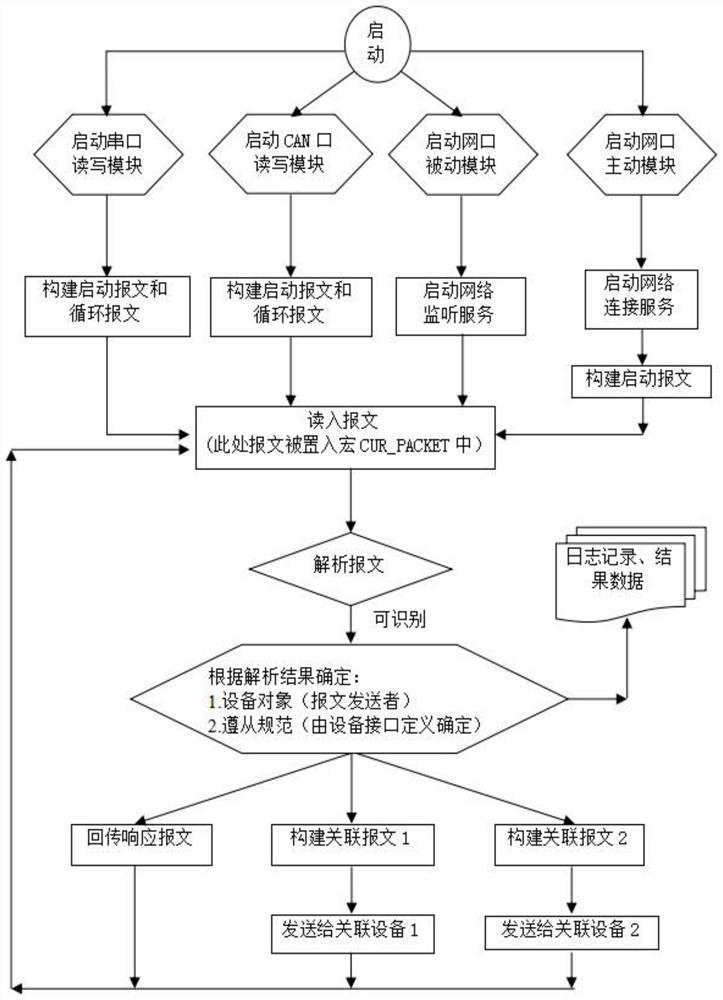

Intelligent programmable response system

PendingCN114115829AEasy to runGuaranteed uptimeProgramming languages/paradigmsCode compilationEngineeringReal-time computing

The invention relates to intelligent control, in particular to an intelligent programmable response system which comprises a programmable response module, an interface information configuration module, a message configuration information definition module and an initialization module. The message configuration information definition module carries out structural model definition on all messages which can be identified by a system from an abstract level, the initialization module determines an interface type and a starting action according to interface information and initializes a message type library and a processing process description language according to a structural model, and the programmable response module judges the type of the received message and sends the message to the system. Meanwhile, sensing circulation is carried out on the real running state of the message sender, and a return message and an associated message of a specified type are constructed and sent to the message sender and the associated equipment respectively; according to the technical scheme, the defects that in the prior art, operation logic cannot be programmed, and function extension is difficult can be effectively overcome.

Owner:安歌智慧科技(上海)有限公司

A test method and system for L2TP tunnel specification

InactiveCN100486187CImplement stress testingReduce testing costsData switching networksComputer hardwareTest facility

Owner:HUAWEI TECH CO LTD

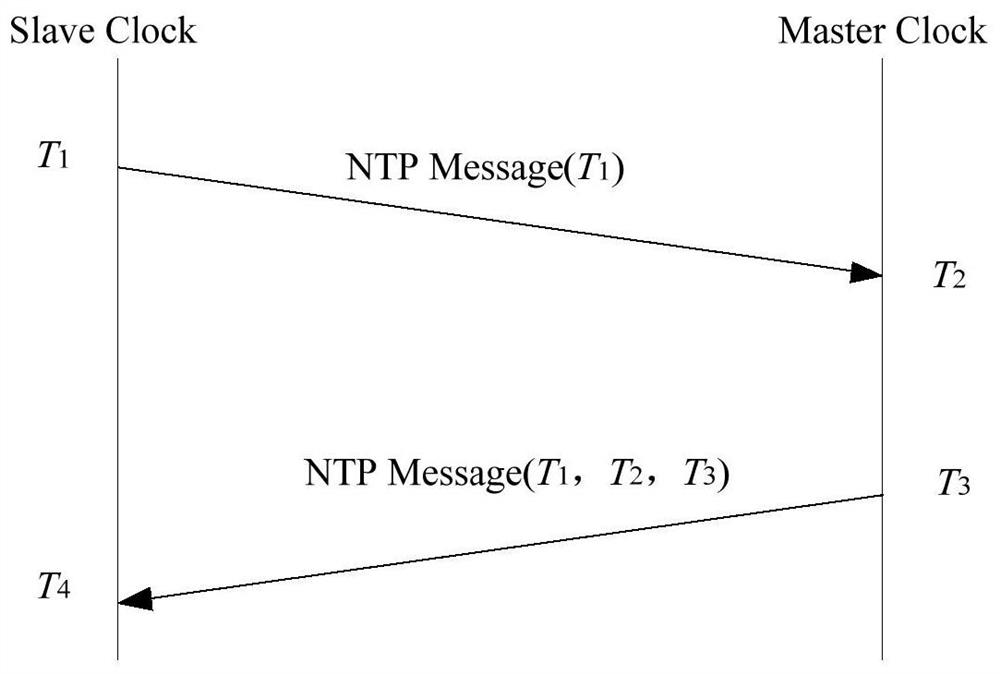

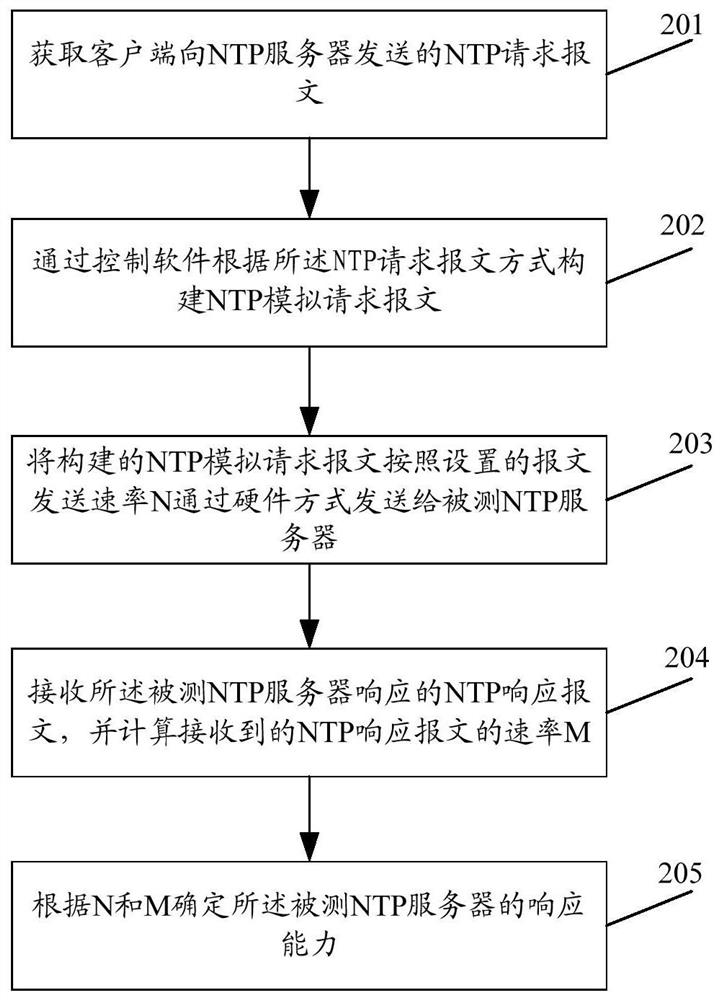

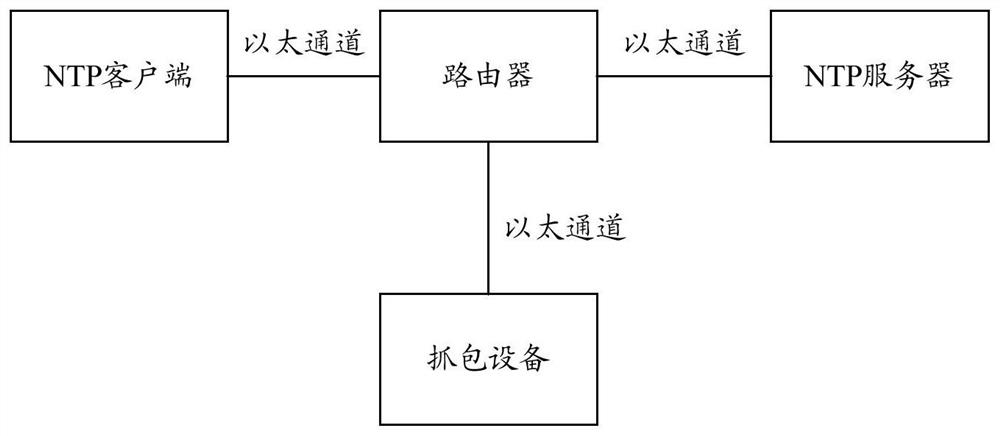

Network time protocol stress testing method and device

ActiveCN112134750BImplement stress testingTime-division multiplexTransmissionTime ProtocolEngineering

The present application provides a network time protocol stress testing method and device, the method comprising: obtaining an NTP request message sent by a client to an NTP server; constructing an NTP simulation request message according to the NTP request message through control software, The NTP simulation request message of construction is sent to the tested NTP server by hardware according to the message transmission rate N set; Receive the NTP response message of the NTP response message of the tested NTP server, and calculate the NTP response message received rate M; determine the response capability of the tested NTP server according to N and M. This method can realize high-rate NTP server stress testing.

Owner:CHINA ACADEMY OF INFORMATION & COMM +1

Water meter multiple pressure value and flow value comprehensive performance testing system and testing method

ActiveCN108332823AVerify performanceAccurate data supportTesting/calibration for volume flowPore water pressureEngineering

The invention relates to a water meter multiple pressure value and flow value comprehensive performance testing system which comprises a front measuring unit and a rear measuring unit. The front measuring unit comprises a pressure sensor I, a booster pump and a pressure reducing valve, the pressure sensor I is used for detecting a pressure value of a testing working section, the booster pump and the pressure reducing valve are connected with a starting end pipeline of the testing working section and used for adjusting water pressure of the testing working section, and the rear measuring unit comprises a pressure sensor II, a standard pressure gauge and a standard electronic flow meter, the standard pressure gauge and the standard electronic flow meter are used for comparing set values. According to the system, the pressure value can be transformed along with testing requirements in real time, an instantaneous flow value is automatically adjusted, the system can accurately simulate different working conditions possibly met by a water meter in actual use process through automatic adjustment of different pressure values and different instantaneous flow values, the comprehensive performance of the water meter is comprehensively verified, an accurate data support is provided for performance improving of the water meter, static comprehensive pressure is tested, the comprehensive performance of dynamic multiple pressure values and instantaneous flow values are tested, and ultimate safety of the water meter is tested.

Owner:东莞市奥纳水务科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com