Water meter multiple pressure value and flow value comprehensive performance testing system and testing method

A comprehensive performance test and test system technology, which is applied in the field of water meter multi-pressure value and flow value comprehensive performance test system, can solve the problem that there is no test system, it is impossible to prepare and record the instantaneous limit pressure value of the water meter structure, and it is impossible to accurately understand the maximum pressure of the water meter structure Ability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

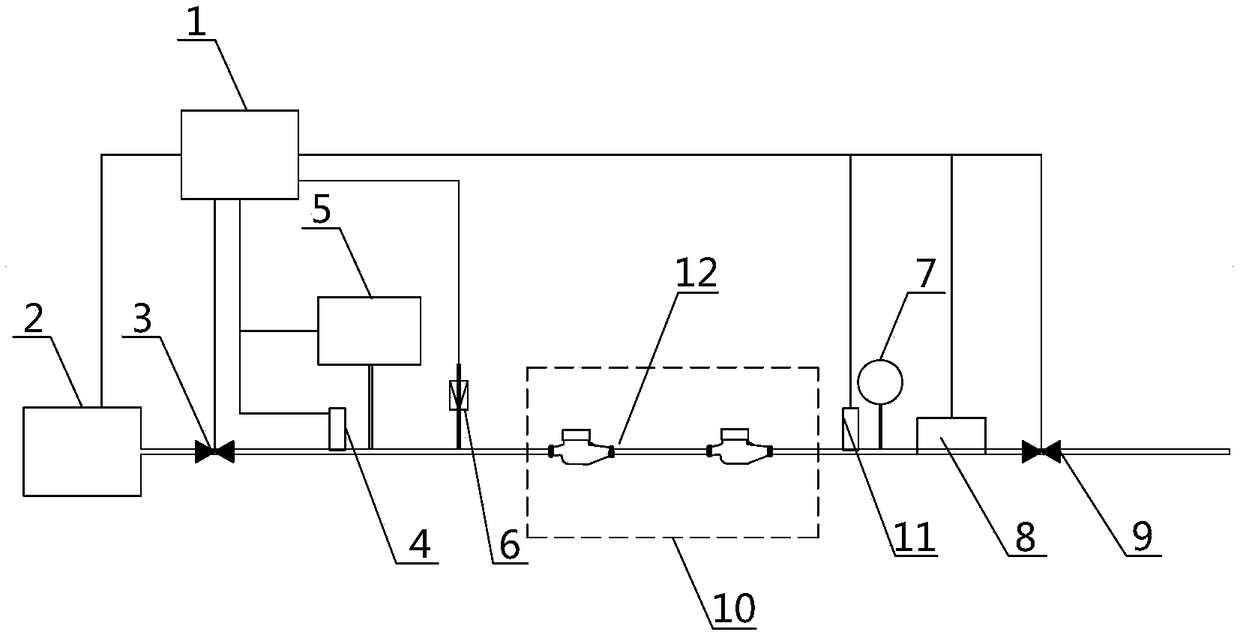

[0043] Such as figure 1 As shown, in the water meter multi-pressure value and flow value comprehensive performance testing system described in Embodiment 1 of the present invention, the purpose of the implemented technical means is to solve the problem that traditional testing equipment does not have the ability to realize various tests through external automatic control. The test system of the target causes the problems that the pressure value cannot be quickly switched, the maximum pressure bearing capacity cannot be determined, and the test function of different working conditions cannot be satisfied. Therefore, the technical solution implemented by the present invention includes measuring the water meter test working section 12 and surrounding it. The water inlet and outlet pipelines constitute the measurement unit of the measurement system, and the implemented measurement system also includes an externally configured PLC control unit 1 .

[0044] Further analysis of the w...

Embodiment 2

[0057] Such as figure 1 As shown, the water meter multi-pressure value and flow value comprehensive performance test system described in the second embodiment of the present invention, the second embodiment is a test method for comprehensive pressure testing under static conditions formed on the basis of the first embodiment, specifically Proceed as follows:

[0058] (1) After the PLC control unit 1 configured in the test system confirms that the preparatory work is completed, turn off the water supply of the high-pressure water inlet pump 2 with a frequency conversion device, and at the same time turn off the valve on the water inlet and outlet pipe sections of the equipment;

[0059] (2) The booster pump 5 connected to the test section 12 inside the test system starts to work. When the pressure sensor Ⅰ4 detects that the pressure of the test section 12 reaches the set value, the booster is stopped and the static pressure test is started. When the set value is reached, it ca...

Embodiment 3

[0063] Such as figure 1 As shown, the multi-pressure value and flow value comprehensive performance test system of the water meter described in the third embodiment of the present invention, the third embodiment is formed on the basis of the first embodiment and the second embodiment for dynamic multi-pressure value and instantaneous The test method of the comprehensive performance test of the flow value, the specific steps are as follows:

[0064] (1) After the PLC control unit 1 confirms that the relevant preparatory work is completed, the frequency conversion device is automatically controlled by the PLC control unit 1, and the high-pressure water inlet pump provides the water pressure required for the test. By adjusting the area of the water outlet cross-section of the high-pressure valve 9 at the end of the test section 12 The instantaneous flow rate required by the setting is obtained through the control of the PLC control unit 1 (obtained by the comparison and feedbac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com