Pressure-maintaining maintenance seal experiment table

A technology for repairing seals and test benches, which is applied to liquid variable displacement machinery, pump testing, machine/engine, etc., and can solve problems such as long time, difficulty, loss and waste of working gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

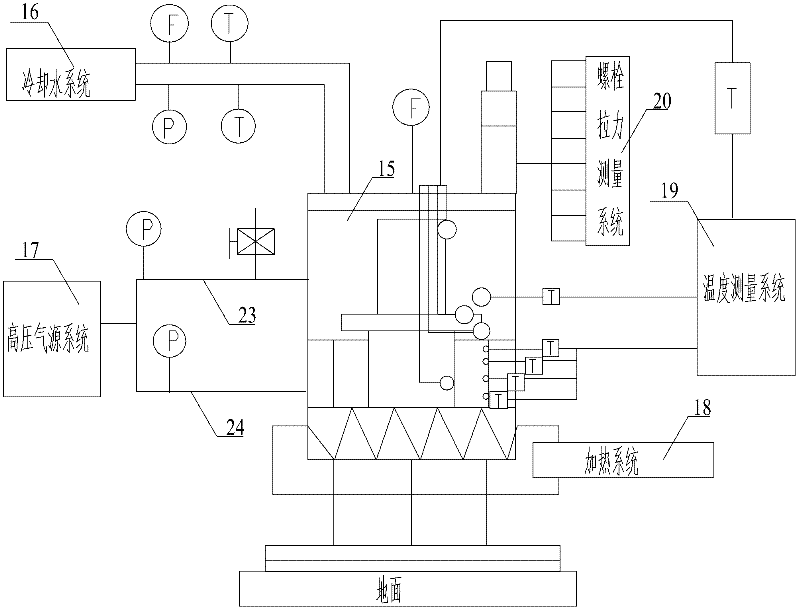

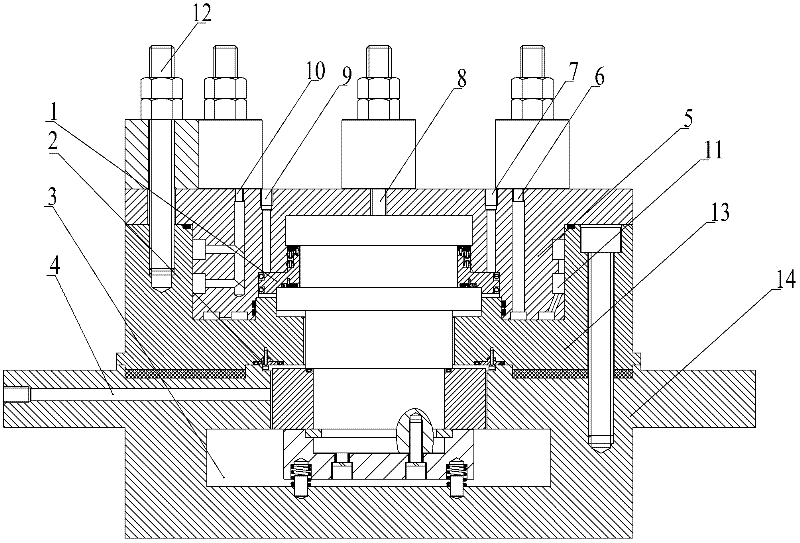

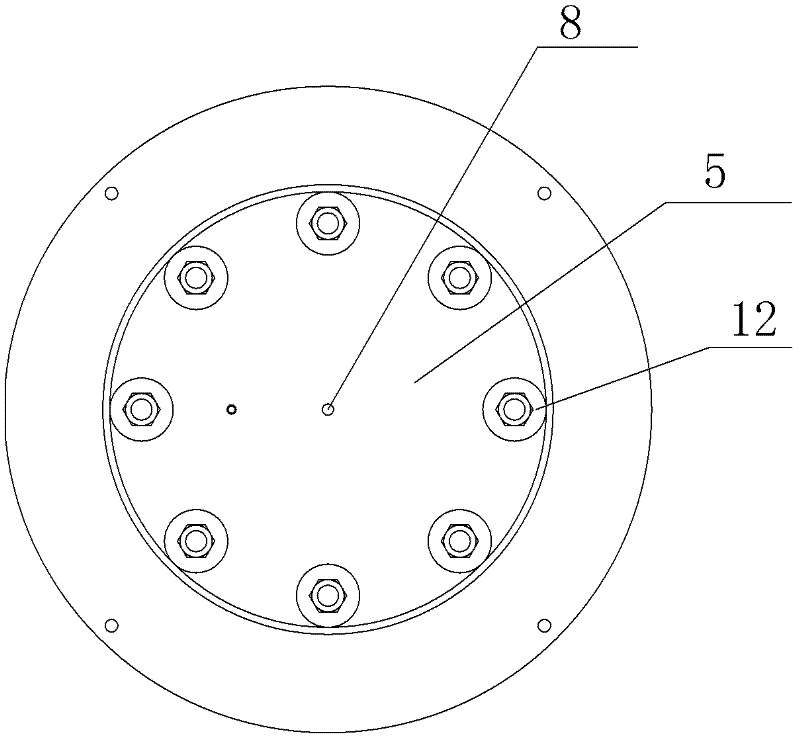

[0026] like figure 1 As shown, the present invention is a kind of pressure maintaining and repairing sealing experiment bench, comprises the experiment bench body 15 that is used to load the pressure maintaining and repairing sealing device, provides the cooling water system 16 of maintenance test cooling environment for the experiment bench body 15, provides maintenance for the test A high-pressure air source system 17 for gas and working gas, a heating system 18 for providing heating for the test, a temperature measurement system 19 for detecting the temperature distribution of the main shaft of the pressure maintaining and overhauling sealing device and the temperature around the rubber seal of the cooling water jacket 5, and for A bolt tension measurement system 20 for testing the bolt removal of the sealing gland bolts for primary mainten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com