Lip seal test experiment table

A test experiment, lip sealing technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problem of inability to reflect the leak-proof ability of sealing components, inability to judge the quality of processing and assembly of sealing components, and poor machinery and equipment. impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

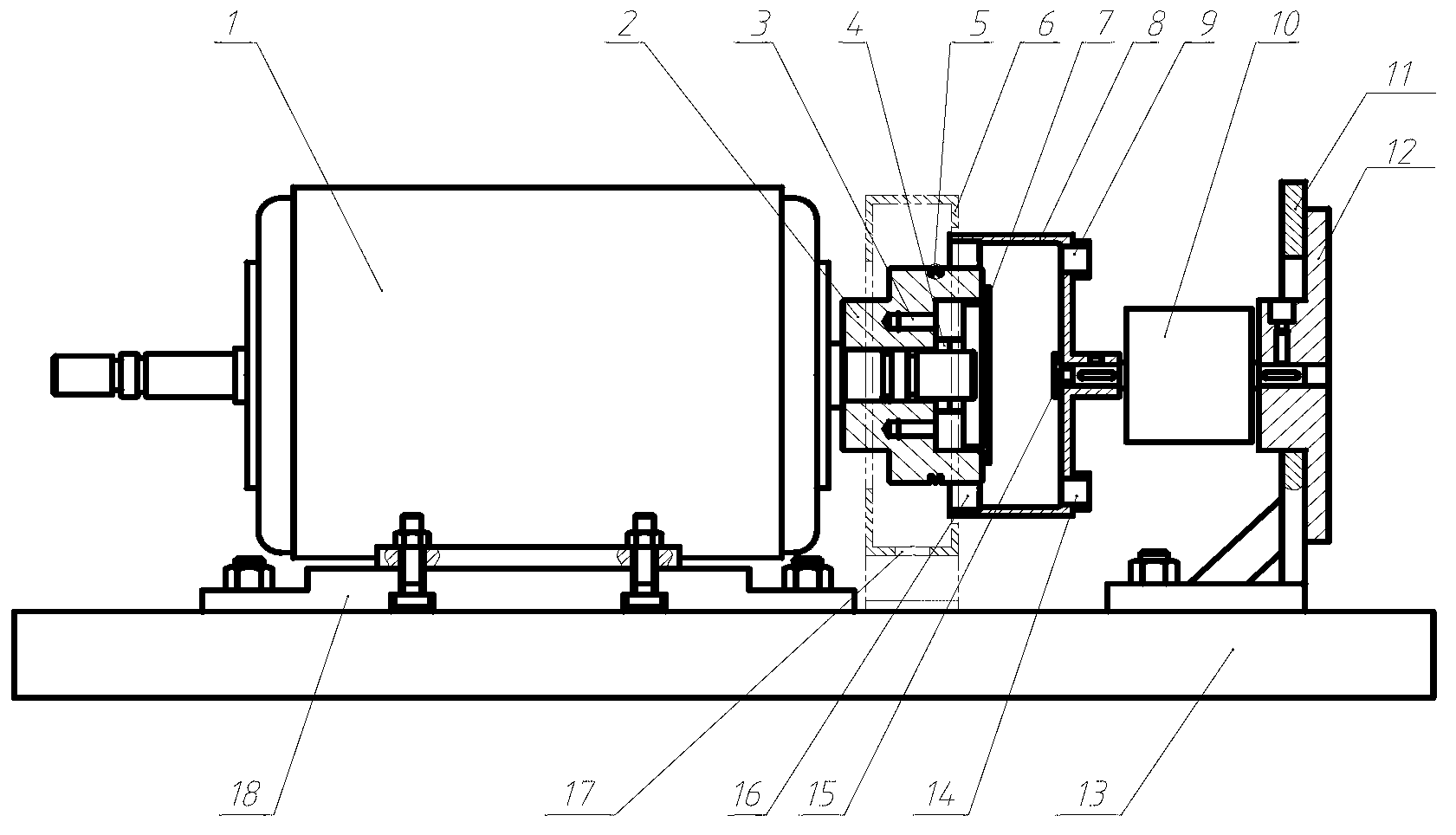

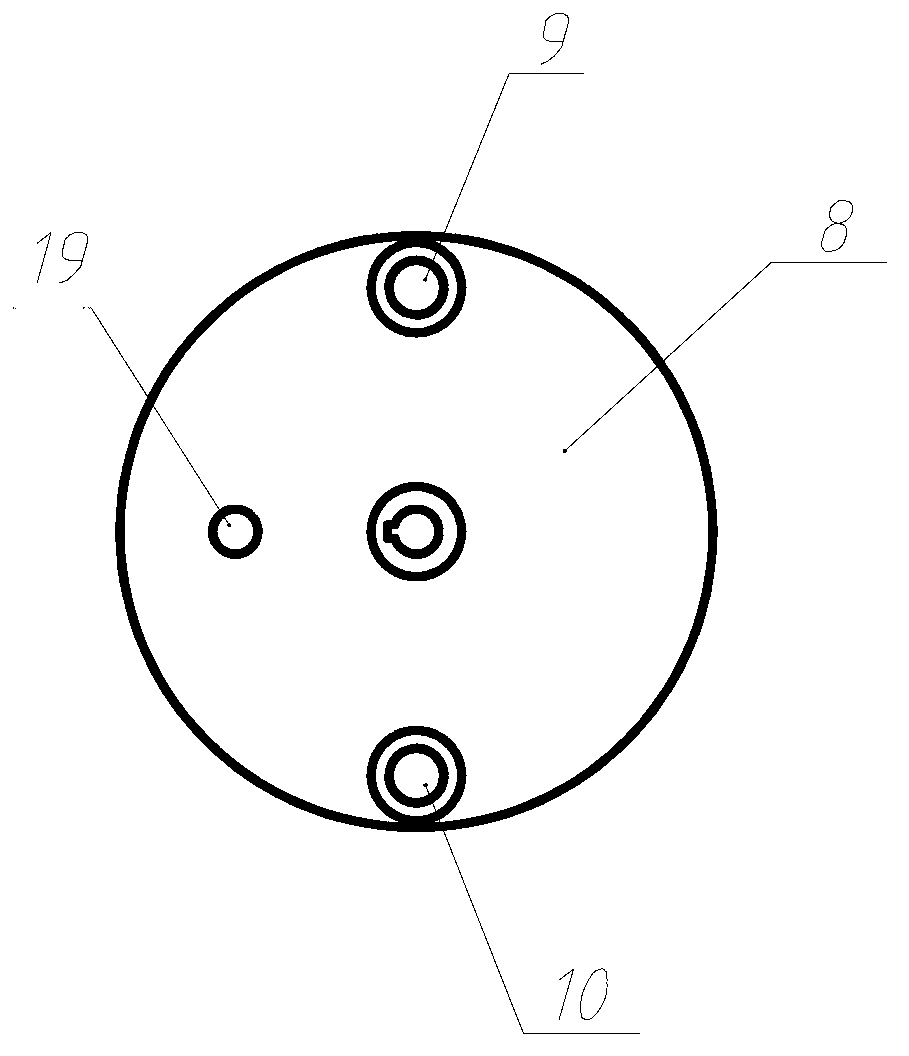

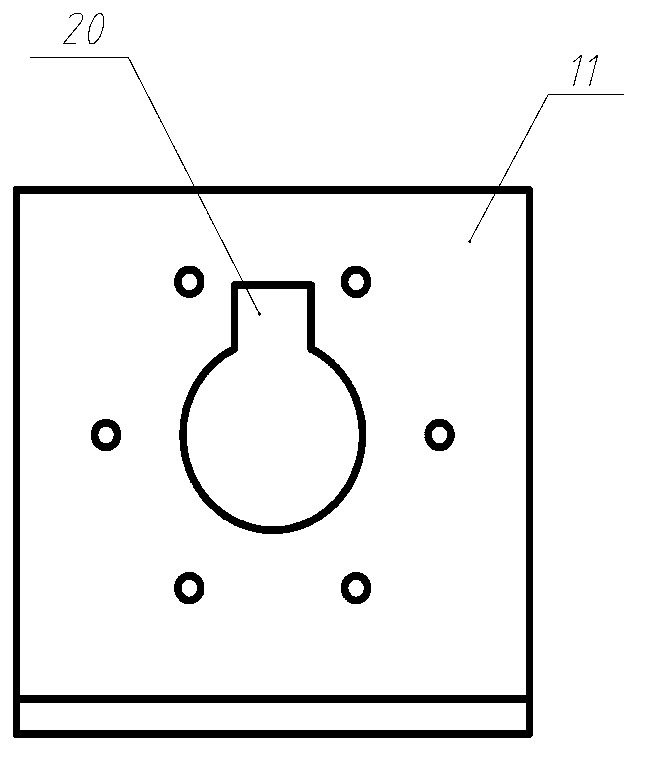

[0014] Refer to attached figure 1 , a lip seal test bench, including a T-slot platform 13, one end of the T-slot platform 13 is provided with a flange support 11, and the other end is equipped with a motor base 18, in order to avoid other parts and flange supports 11, there is a groove 20 on the flange support. An AC motor 1 and an external frequency converter are installed on the motor base 18 to realize stepless speed regulation. The hole 3 is equipped with an oil chamber 8, the oil chamber 8 is keyed to the static torque sensor 10, the right end of the static torque sensor 10 is loaded into the connecting flange 12 through a key connection, and the right end of the connecting flange 12 is fixed to the flange support 11 by bolts ; The shaft sleeve 2 is sleeved with an oil convex point 5, the right side of the shaft sleeve 2 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com