Wire testing machine with wire processing function

A testing machine and testing mechanism technology, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, analyzing materials, etc., can solve problems such as the inability to realize wire processing and the inability to guarantee the accuracy of wire test results, etc., to increase Processing function, the effect of increasing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

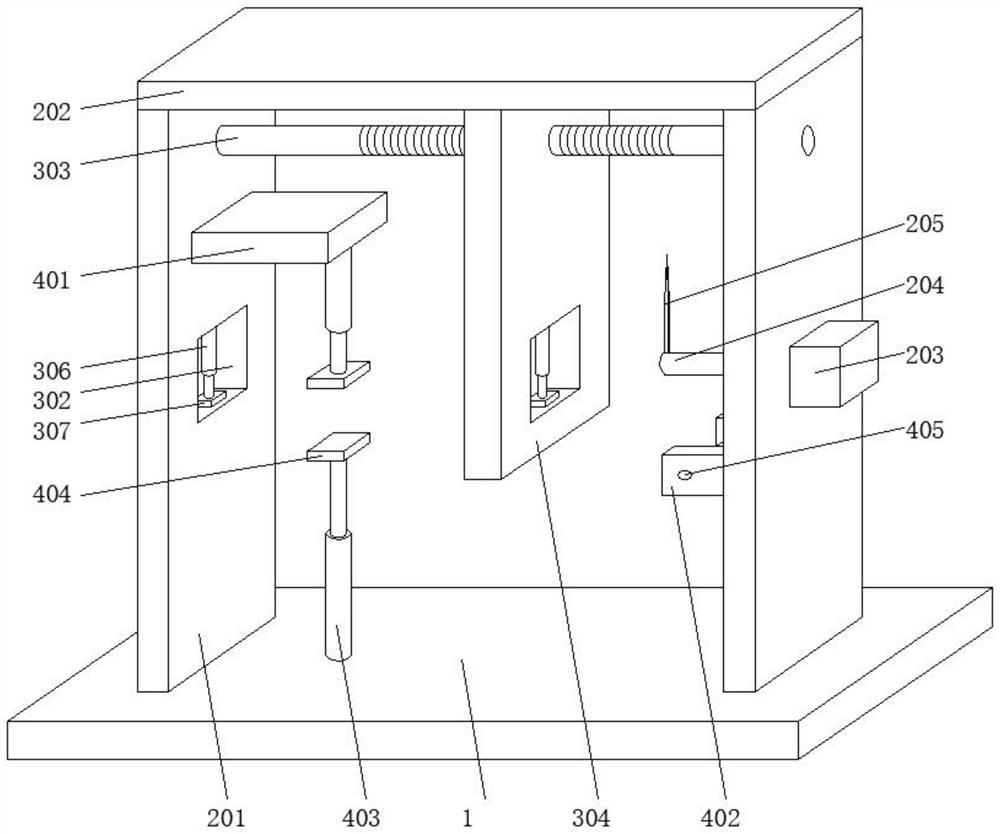

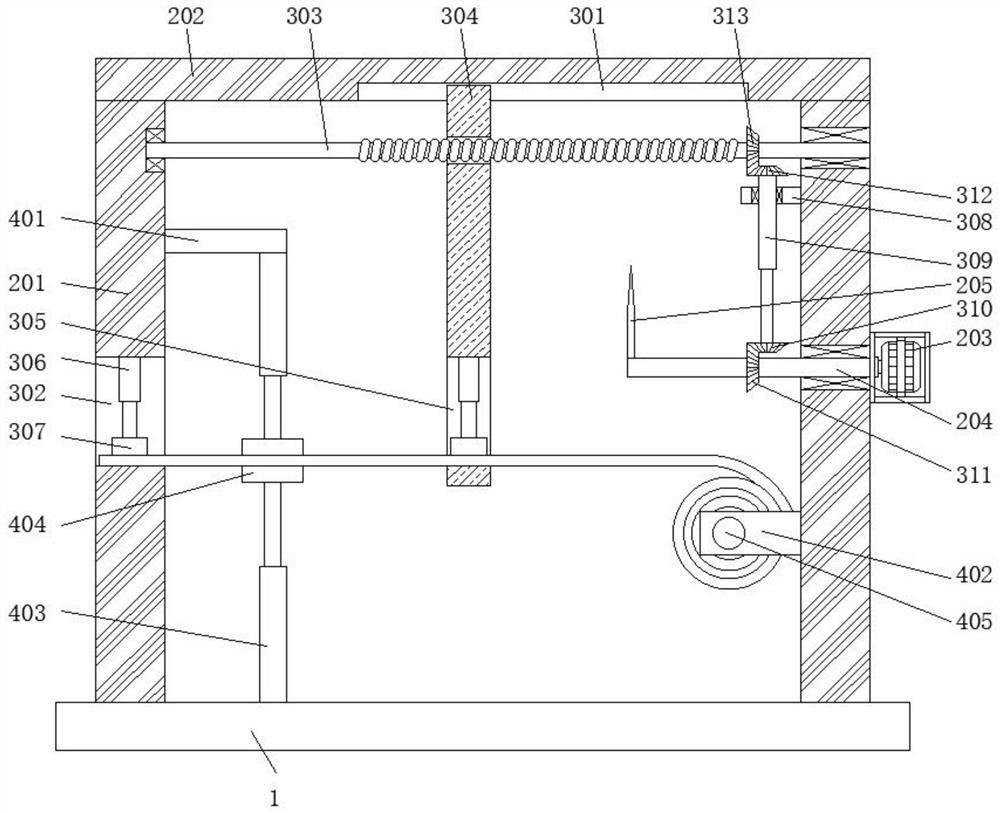

[0032] A wire testing machine with the function of processing wire, including a base 1, and also includes a wire cutting mechanism, a tensile testing mechanism, and a compressive testing mechanism; the wire cutting mechanism is set on the top of the base 1, and the wire cutting mechanism is used for wire processing , the wire cutting mechanism includes a support frame 201 and a top plate 202, the support frame 201 is symmetrically fixed on the top of the base 1, and the top plate 202 is fixed on the top of the two support frames 201; the tensile testing mechanism is located between the support frame 201 and the top plate 202 Between them, the tensile testing mechanism is used for tensile testing of the wire; the compressive testing mechanism is provided on the base 1 and the supporting frame 201, and the compressive testing mechanism is used for testing the compressive and bending resistance of the wire.

[0033] Preferably, a motor 203 is affixed to the right side of the right...

Embodiment 2

[0036] The difference from Example 1 is that it also includes the following:

[0037] The tensile testing mechanism comprises a limit groove 301, a vertical groove 302 and a long rod 303, the limit groove 301 is arranged at the bottom of the top plate 202, the vertical groove 302 is arranged on the left support frame 201, and the long rod 303 is rotatably connected to two supports. Between racks 201.

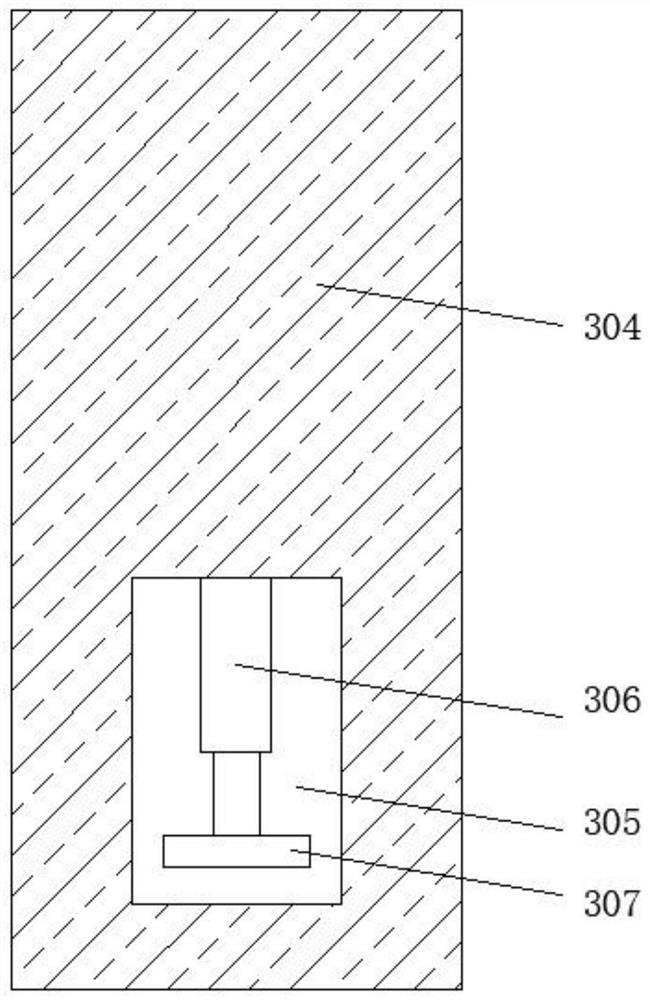

[0038] Preferably, the long rod 303 is provided with a threaded groove, the long rod 303 is threadedly connected with a moving plate 304, the moving plate 304 is provided with a hollow groove 305, and the inside of the vertical groove 302 and the hollow groove 305 are fixedly connected with a first hydraulic telescopic Rod 306, the bottom of the first hydraulic expansion rod 306 is fixedly connected with a fixed plate 307, the bottom of the fixed plate 307 is provided with a protrusion, and the right fixed plate 307 is provided with a tension tester.

[0039] The first hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com