Method for using negative pressure perforation technology for realizing pressure recovery well logging interpretation

A technology of negative pressure perforation and logging interpretation, which is applied in the directions of measurement, production of fluids, and earth-moving drilling, etc., can solve the problems of prolonging the completion period, secondary downhole pollution, and testing time lag, reducing labor intensity and shortening Completion time, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Well He 60-Xie 45 is a new well in a high-pressure low-permeability reservoir in the Xianhe area. The average air permeability of the reservoir is 13.6 mD, the porosity is 18-23.5%, and the shale content is 14-28%. The well requires the use of negative pressure perforation, assisted pressure recovery test to obtain productivity and formation coefficient, and determine the next production plan. See Table 1 below for details.

[0035] Basic Data Table 1 of Well He 60-Xie 45

[0036]

[0037] (1) Negative pressure value: The pressure gauge is placed 60 meters above the perforating gun. The pressure before the perforating gun detonates is 14.2MPa, and the actual negative pressure is 16.2Mpa. (The factors such as well deviation are not considered). Such as figure 1 shown.

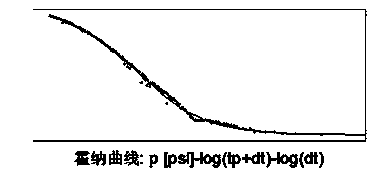

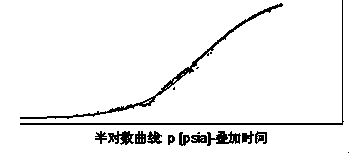

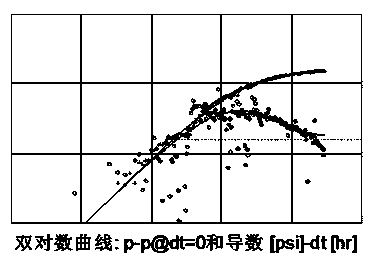

[0038](2) Formation pressure: The pressure in the oil layer before perforation was 14.2Mpa. After the perforating gun detonated, the formation fluid entered the wellbore. After about 1 hour of test...

Embodiment 2

[0044] Well He 183-1 is a new well in a high-pressure low-permeability reservoir in the Xianhe area in 2012. It is required to use negative pressure perforation and assist in pressure recovery tests to obtain productivity and formation coefficients and determine the next production plan. See Table 2 below for details.

[0045] Drilling Basic Data Table Table 2

[0046]

[0047]

[0048] (1) Negative pressure test situation

[0049] In March 2012, negative pressure continuous testing was carried out on the well. Before the perforating gun detonated, the pressure in the oil layer was 7.5MPa, and the actual negative pressure was 24.6Mpa. Such as Figure 5 shown.

[0050] After about 72 hours of testing, the formation pressure rose to 18.9MPa, and the packer was unsealed and the tubing was pulled out. During the period after perforation, the formation pressure increased by 11.4MP, and the liquid level in the tubing increased by 1140m (calculated based on the specific gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com