Rotary sliding disc type pressure electronic scanning valve

An electronic scanning and rotating disk technology, applied in the measurement of fluid pressure, measuring devices, instruments, etc., can solve the problems of inconvenient installation, unrealized sensors, large product volume, etc., to reduce the overall structural volume, expand the scope of application, and achieve The effect of automatic calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

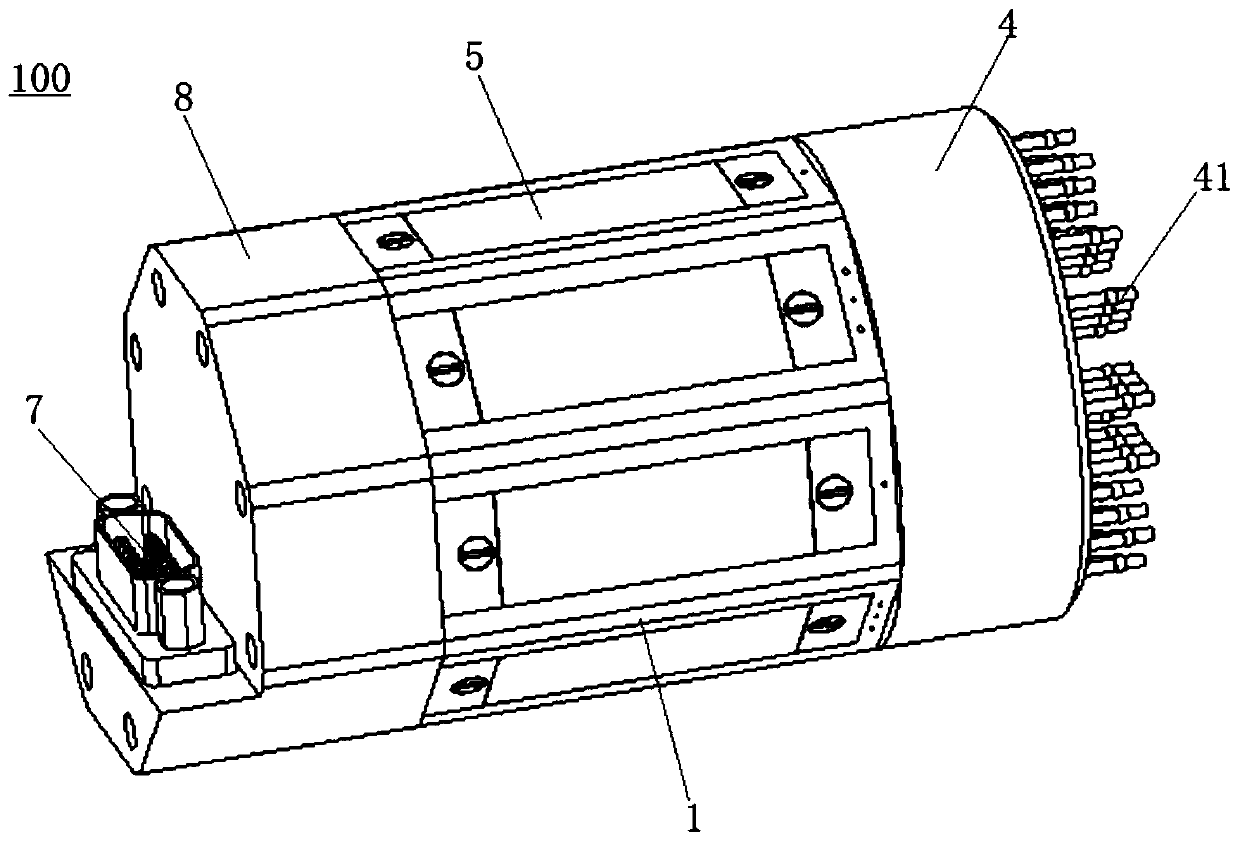

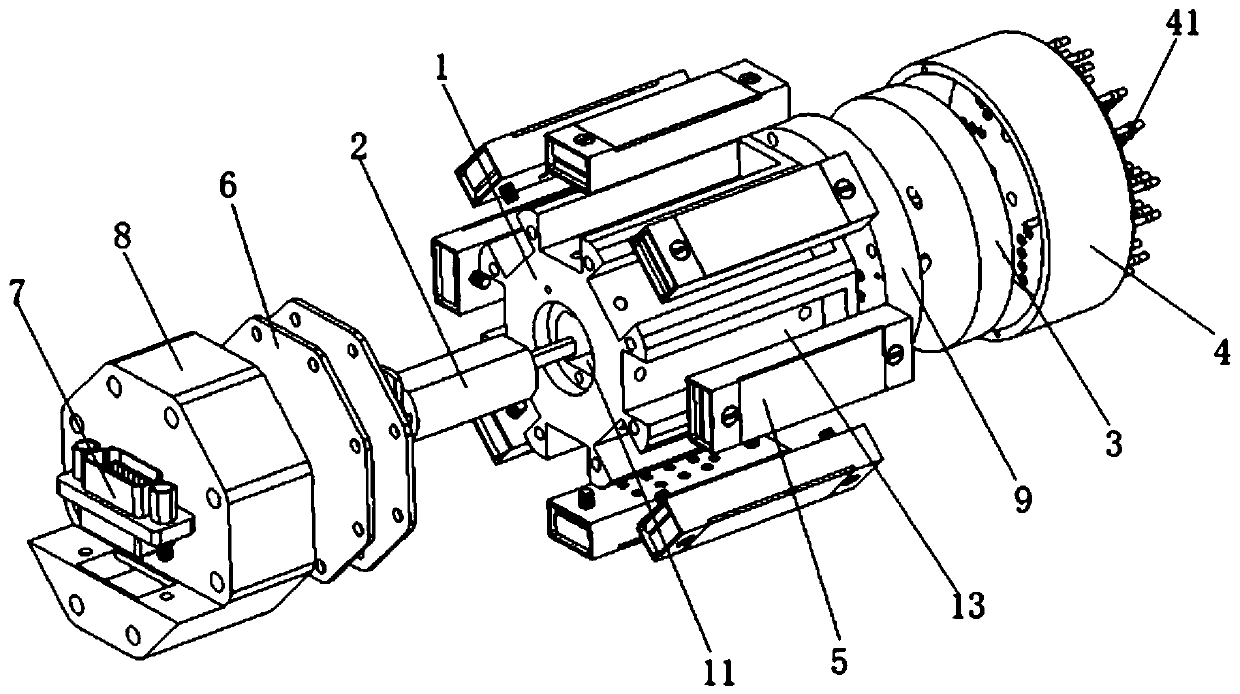

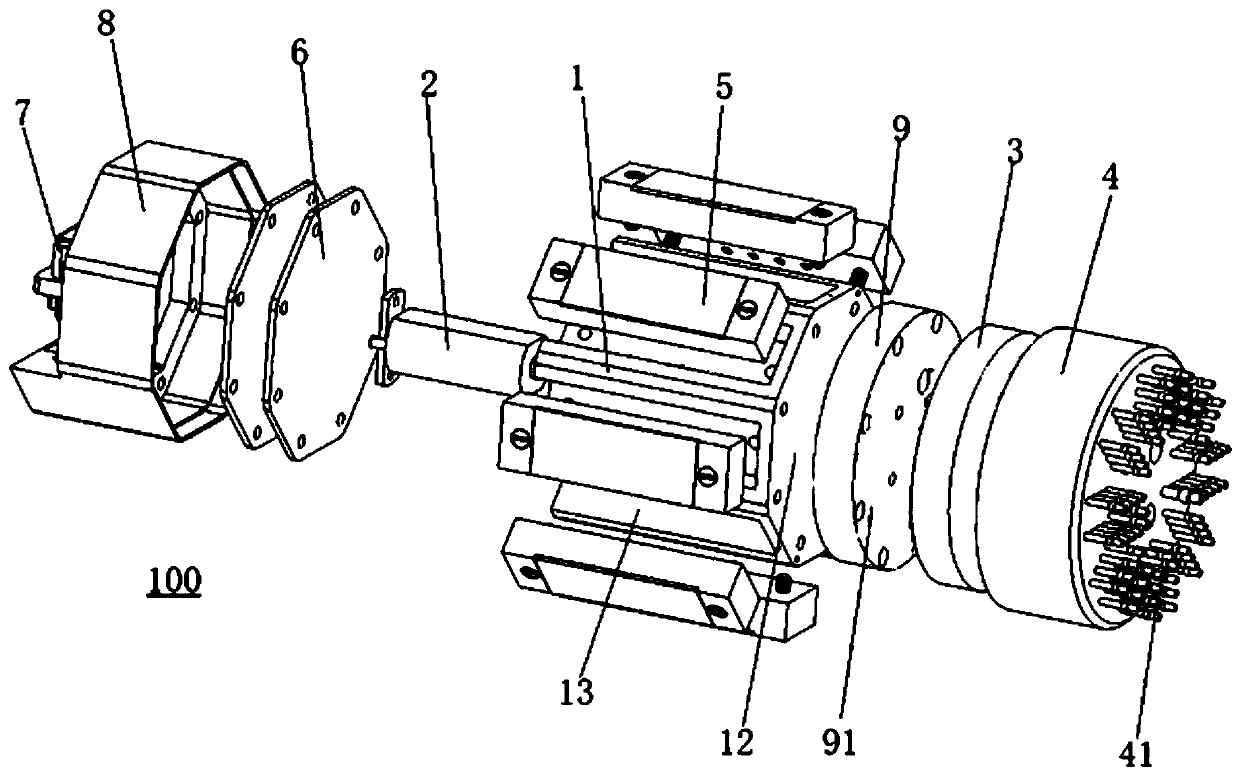

[0030] Please refer to Figure 1-Figure 9 , the present embodiment is a rotary slide plate pressure electronic scanning valve 100, which includes a mounting bracket 1 with a hollow cavity 11 inside, a rotary drive member 2 placed in the hollow cavity 11, driven by the rotary drive member 2 The rotating disk 3 that is rotated and switched between the first position state or the second position state, the front end cover 4 that wraps the rotating disk 3 inside, and several ring-shaped distribution and embedded on the outer peripheral surface of the mounting bracket 1 The pressure sensor assembly 5, the circuit board 6 in circuit communication with the pressure sensor assembly 5, the connector joint 7 in circuit communication with the circuit board 6; the front cover 4 is provided with a number of first air guide needle tubes 41 and second air guide needle tubes 42, The installation bracket 1 is provided with a first group of passages 12 communicating with the pressure sensor ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com