MDL-based nondestructive testing device for local stress distribution of ferromagnetic material

A ferromagnetic material, non-destructive testing technology, which is used in measuring devices, material magnetic variables, and magnetic field measurement using permanent magnets. The effect of quick detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and examples. It should be understood that the following examples are intended to facilitate the understanding of the present invention, and have no limiting effect on it.

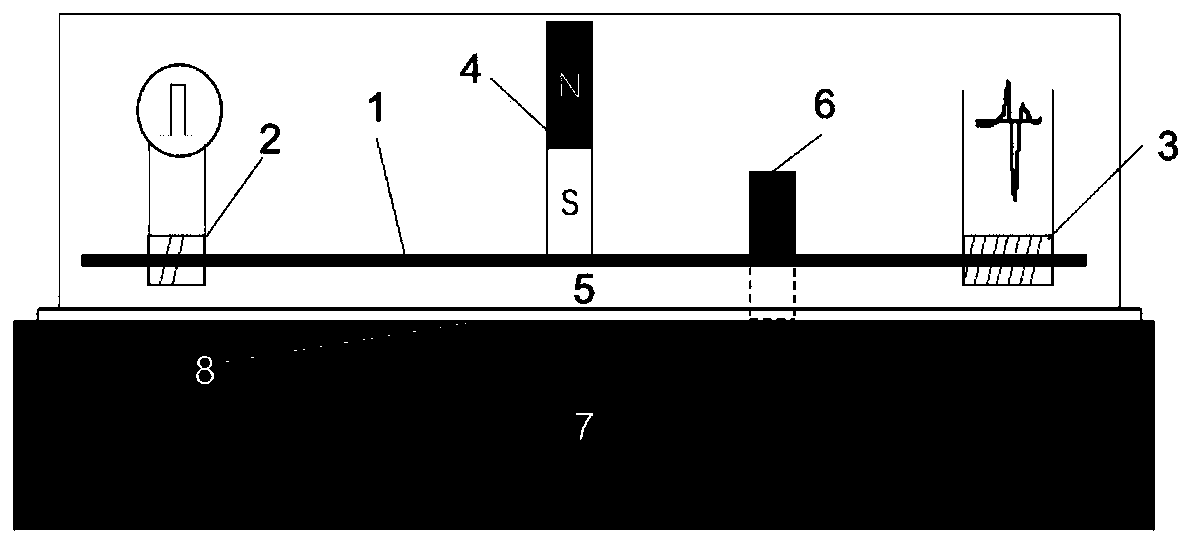

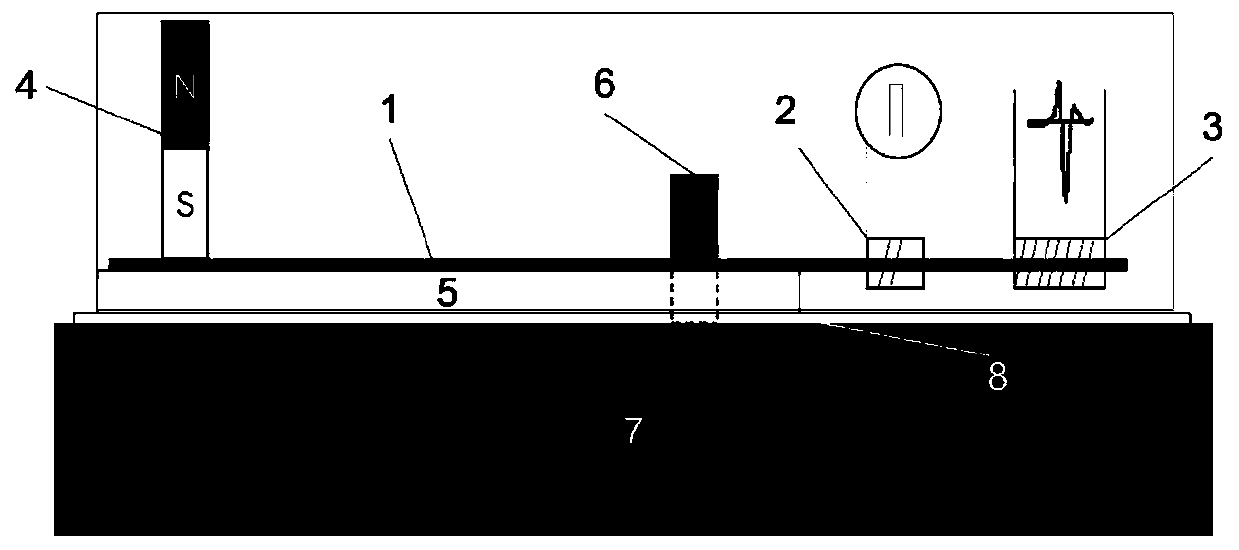

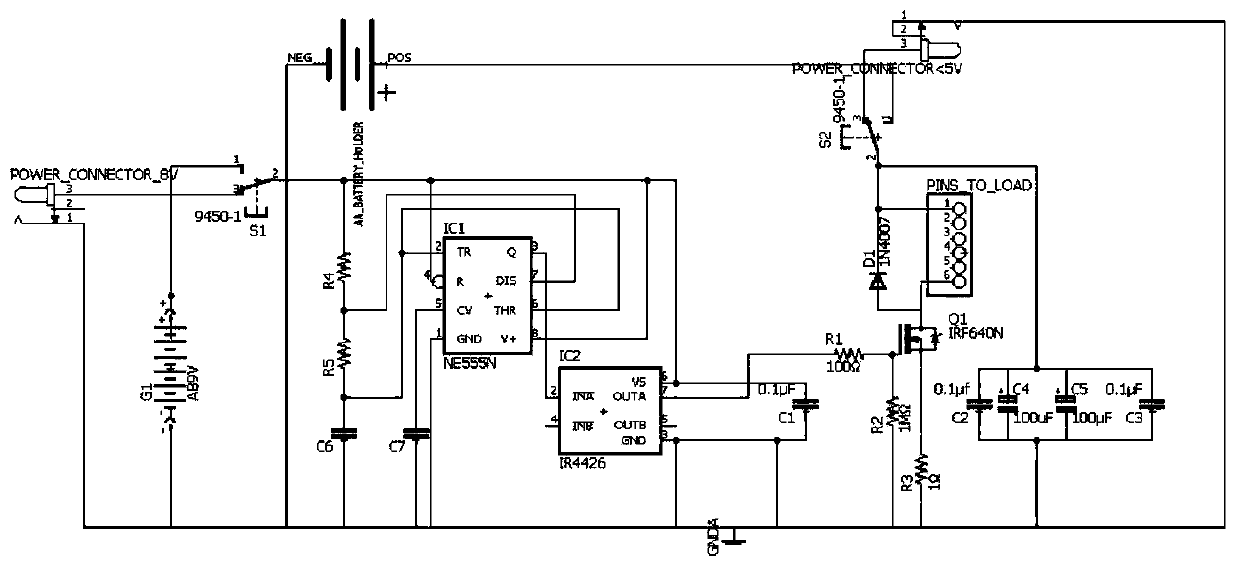

[0031] Such as figure 1 As shown, the MDL-based nondestructive detection device for local stress distribution of ferromagnetic materials provided by an embodiment of the present invention includes an MDL1 with a uniform cross section, an excitation coil 2, a detection coil 3, a Nd-Fe permanent magnet 4, and an aluminum support plate 5, Ultrasonic echo detector 6, and lubricating oil 8 between the aluminum support plate 5 and the ferromagnetic steel 7 to be tested.

[0032] exist figure 1 In the example shown, MDL1 is placed flat on the top of the ferromagnetic steel 7 to be tested as an acoustic waveguide, the excitation coil 2 and the detection coil 3 are respectively wound around the two free ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com