Method for testing pressure during heating process of explosive and propellant columns

A pressure test and heating process technology, applied in the direction of material explosion, can solve problems such as unsatisfactory, and achieve the effect of reducing test costs, realizing pressure testing, and realizing reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

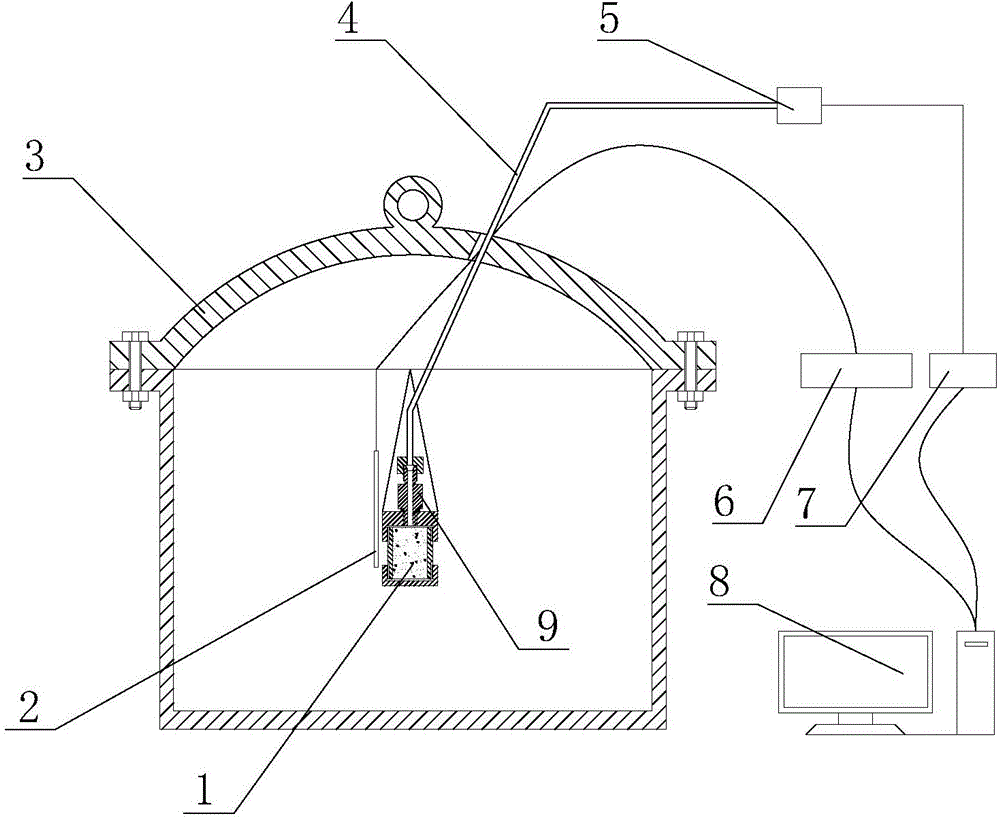

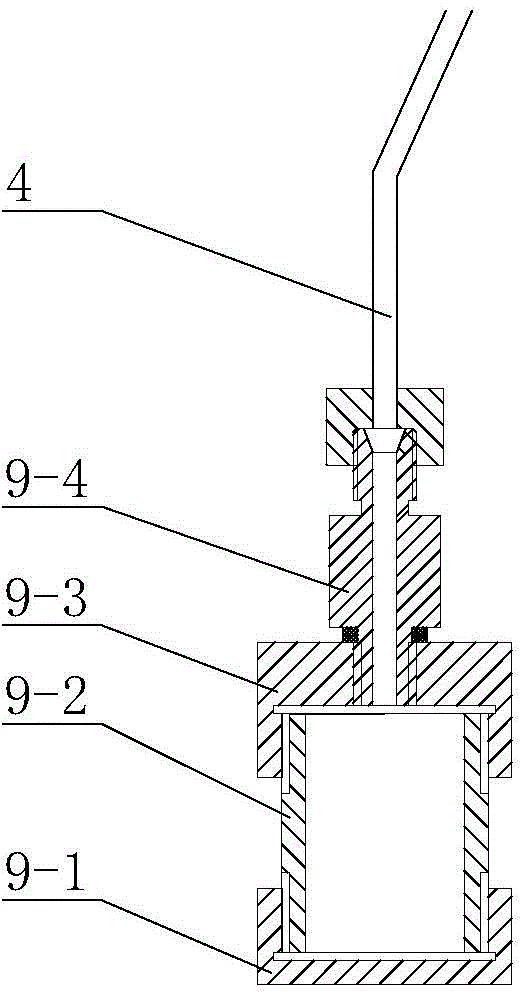

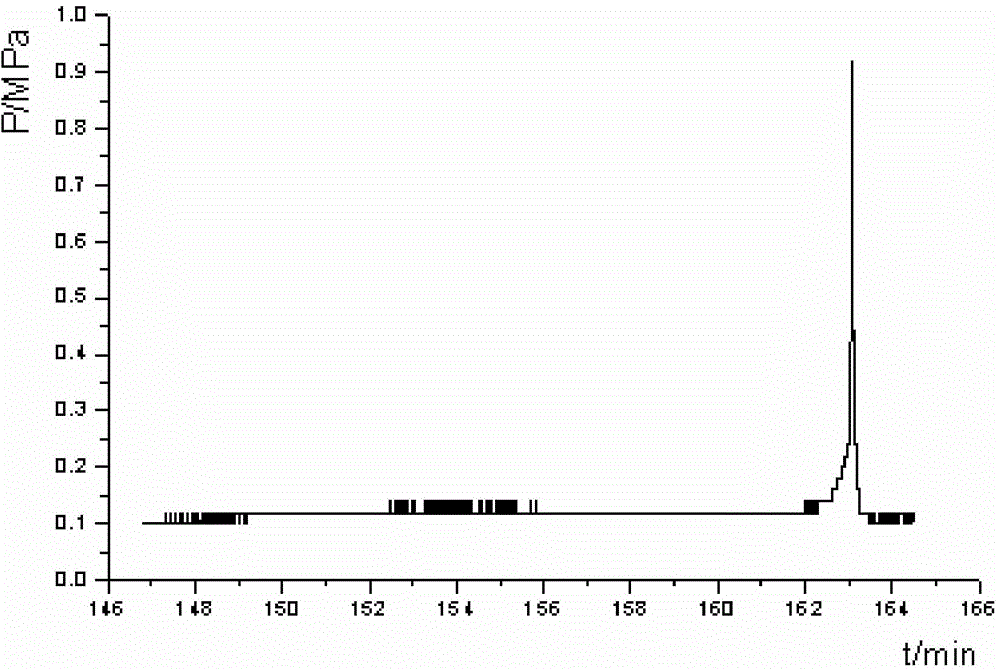

[0037] The present embodiment is the pressure test of 65g AP explosive in the simulated burn-off bomb during the heating process. The simulated burn-off bomb used has an inner diameter of 40mm and a cavity height of 30mm. The test method comprises the following steps:

[0038] 1) Press the AP sample into a cylindrical grain 1, the grain size is Φ40mm×30mm, and the pressed grain 1 is stored in the sample temporary storage area;

[0039] 2) Check that the analog roasting bomb 9, the conduit 4 and the pressure sensor 5 are connected without air leakage, and simultaneously check and debug the explosion-proof heating box 3, the temperature sensor 2, the pressure sensor 5, the temperature instrument 6, the pressure instrument 7 and the computer 8, so that Reach the normal working state, turn off all power before installing the charge 1 in the simulated burn-off bomb 9;

[0040] 3) Take out the AP powder column 1 from the sample temporary storage area, put the powder column 1 into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com