L-shaped support for coiler motor

A coiled motor, L-shaped technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve problems such as axial deformation, and achieve the problem of solving axial deformation, improving product quality and use requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

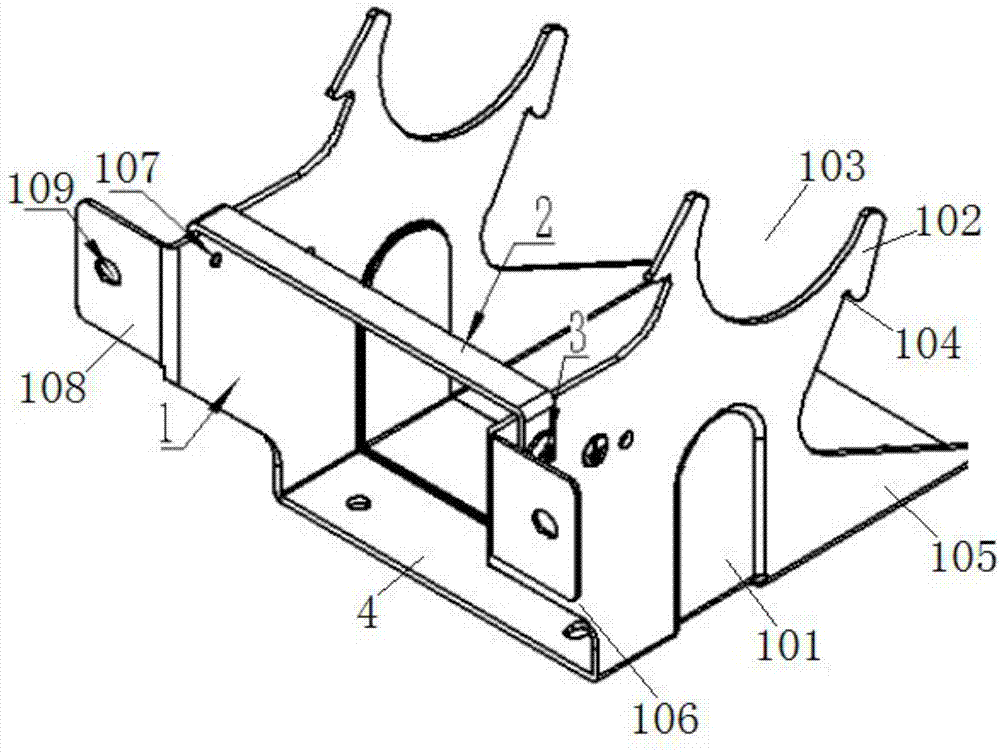

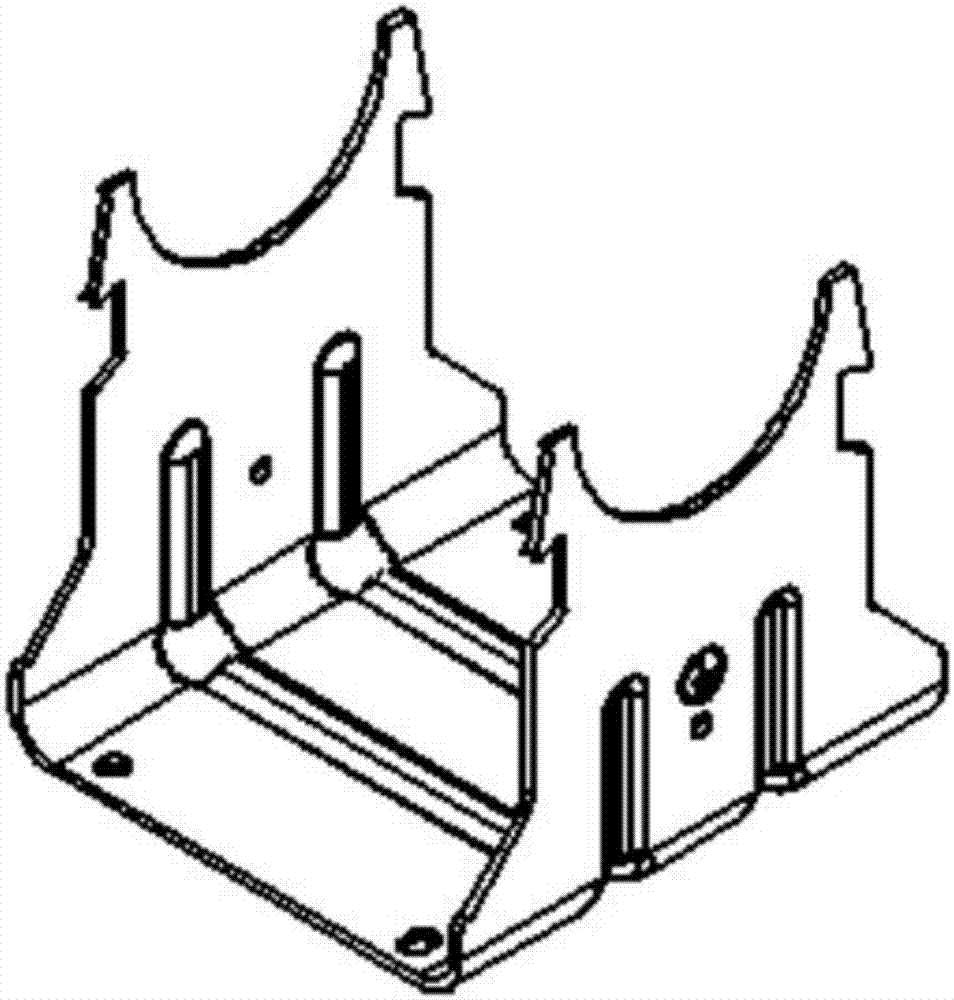

[0020] An L-shaped bracket for a coiled tube motor includes a side plate 1, a supporting plate 2, a fastener 3, and a bottom plate 4. Two side plates 1 are vertically fixed on the surface of the bottom plate 3, and the two side plates 1 are arranged oppositely, such as figure 1 Shown

[0021] The bottom plate 4 is rectangular, and there are four installation through holes on the surface of the bottom plate 4, and the installation through holes are fixed by bolts, so that the bracket is fixed in the four spatial directions of X+ / X- and Z+ / Z-;

[0022] A groove 101 is formed on the surface of the side plate 1, and the groove 101 includes a semicircular groove and a square groove that are connected to each other. The apexes of the side plate 1 are respectively fixed with a supporting plate 102 and a first trapezoidal plate 105, A U-shaped groove 103 is opened on the surface of the support plate 102, a card groove 104 is opened on the outer surface of the side wall of the U-shaped gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com