Machining device for compounding metal hollowed-out framework and high polymer material

A technology of polymer materials and processing devices, which is applied in the field of processing devices and processing devices in which metal hollow skeletons and polymer materials are compounded, can solve problems such as axial deformation of metal hollow skeletons, and can solve the problems of axial deformation and radial deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail with specific embodiment now in conjunction with accompanying drawing:

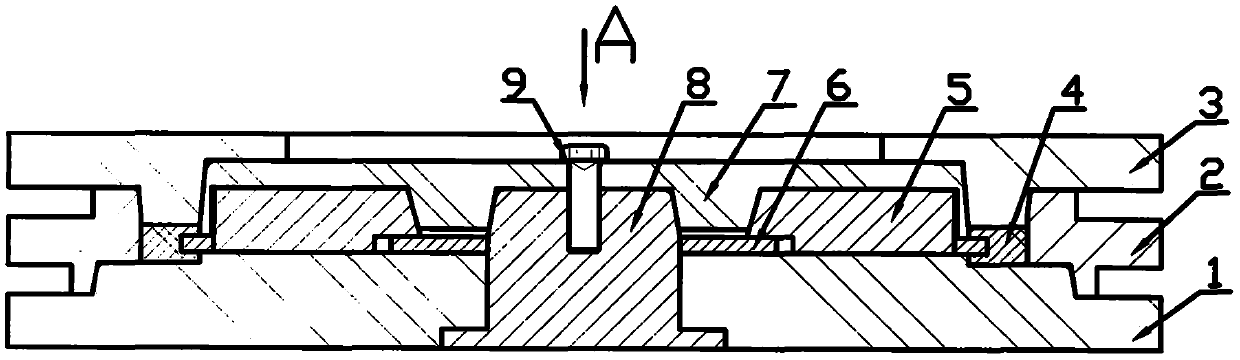

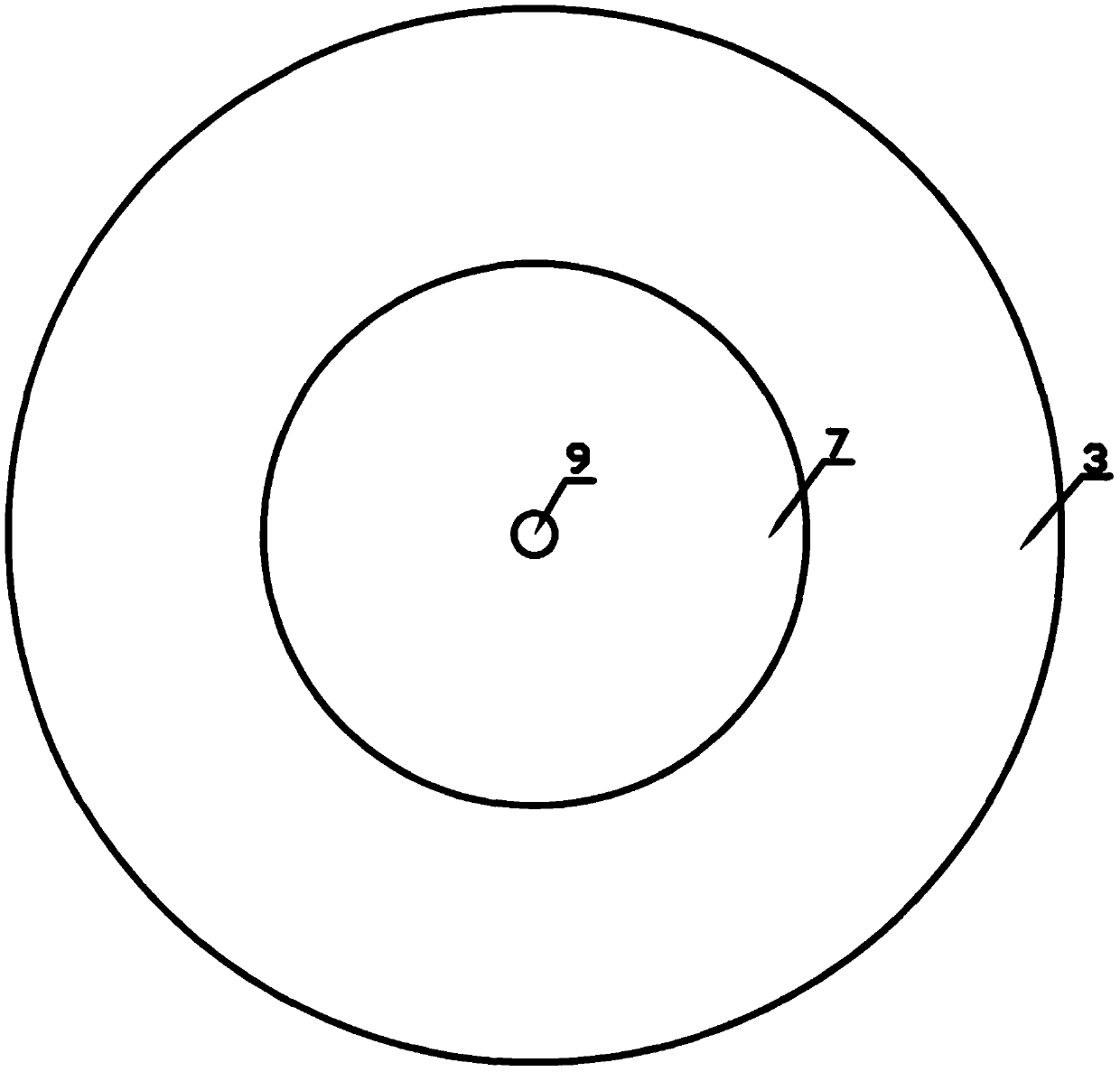

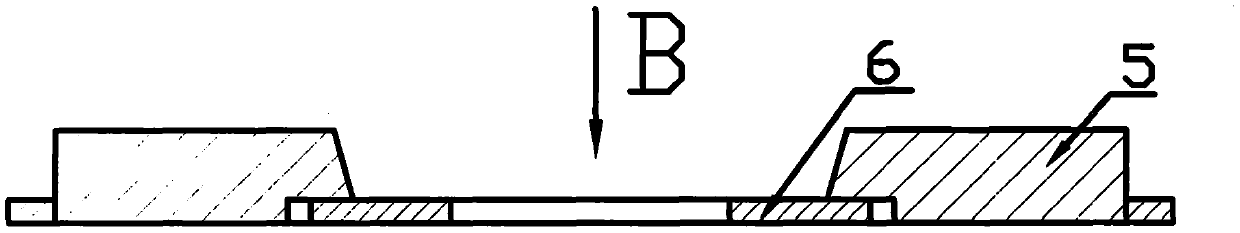

[0019] A processing device for compounding a metal hollow skeleton and a polymer material, which is equipped with a hollow skeleton 6 by positioning a core 8 at the center of a lower mold 1 with two platform structures; two steps are provided on the lower mold 1, One step can control the thickness of the ultra-high molecular weight polyethylene adhesive layer on the lower end surface of the hollow skeleton 6, and the other step is nested with the middle sleeve 2; the inner diameter of the middle sleeve 2 can control the width of the mold cavity 4; the diameter of the hollow skeleton 6 is larger than The diameter of the uppermost round platform of the lower mold 1, which can ensure the size of the polymer adhesive layer turned up on the hollow skeleton 6; the second platform structure of the lower mold 1 is fitted with a middle sleeve 2 nested with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com