Waste tire pyrolysis reactor

A technology of pyrolysis reaction and waste tires, which is applied in the direction of coking ovens, products, and educts, etc., can solve the problems of falling into rakes and discs, locking of stirring shafts, unsuitable for waste tire rubber blocks, etc., and achieve energy saving , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

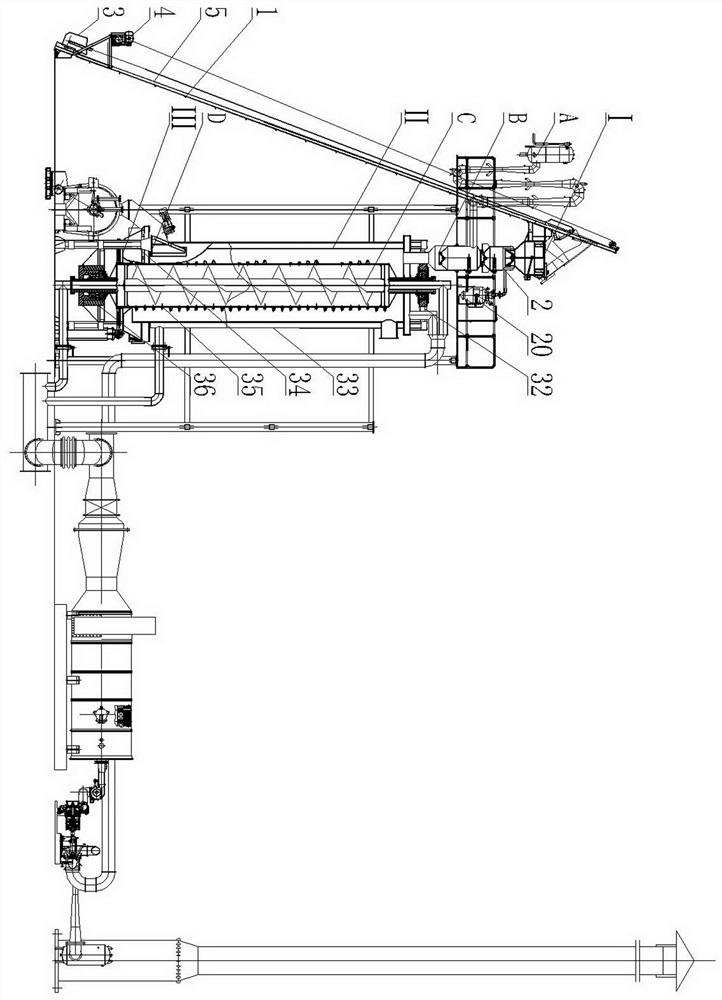

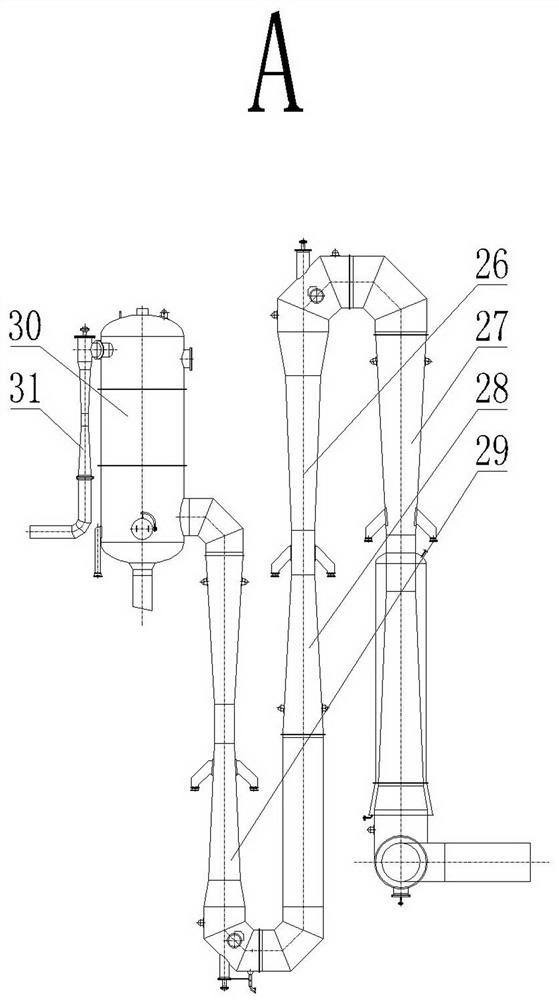

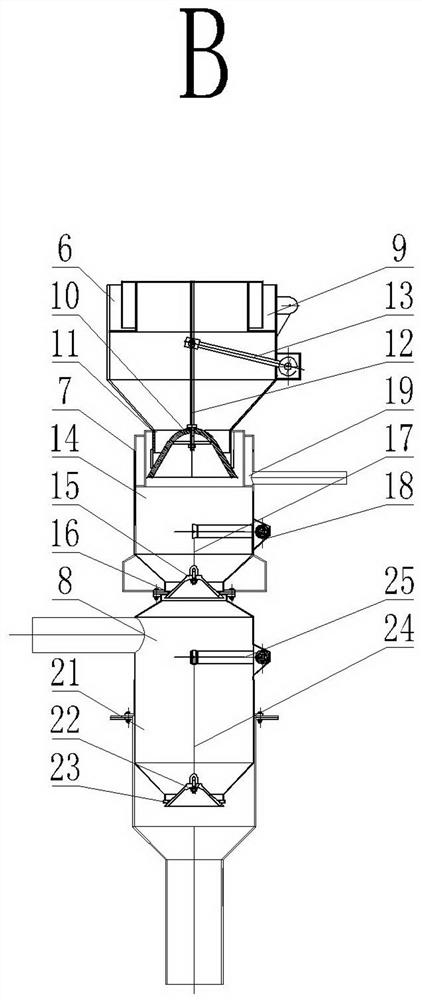

[0062] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, the waste tire pyrolysis reaction furnace is characterized in that it includes a vertical pyrolysis tower II, a feed system I, and a discharge system III.

[0063] The vertical pyrolysis tower II includes a vertical pyrolysis tower body 33, a rotary rake roller 35, an upper bearing seat 32, a lower bearing seat 36, and a support foot 34, and the vertical pyrolysis tower body 33 is designed with a jacket through The high-temperature flue gas at 450-500°C is designed with hollow spiral blades inside the jacket. The high-temperature flue gas rises spirally along the channel formed by the hollow spiral blades, uniformly heating the vertical pyrolysis tower body 33, and avoiding that the high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com