Process method for preparing pyrolysis oil and gas from waste tires

A technology for waste tires and pyrolysis of oil and gas, which is applied in the petroleum industry, preparation of liquid hydrocarbon mixtures, and treatment of hydrocarbon oil, etc. It can solve the problems of not disclosing technical details of recovery of pyrolysis oil and gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

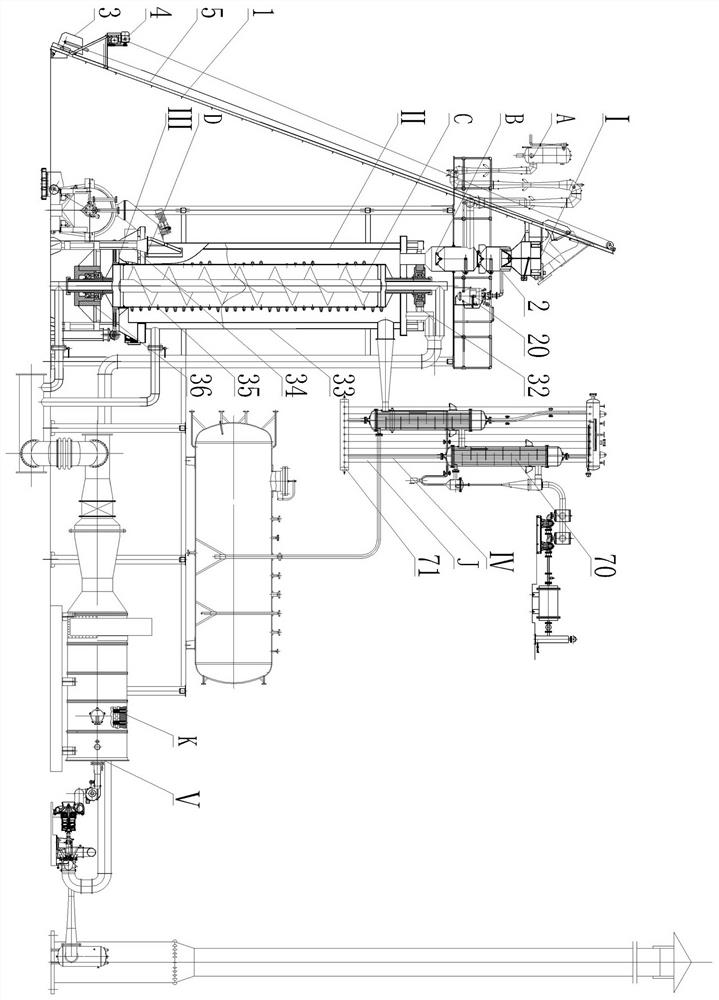

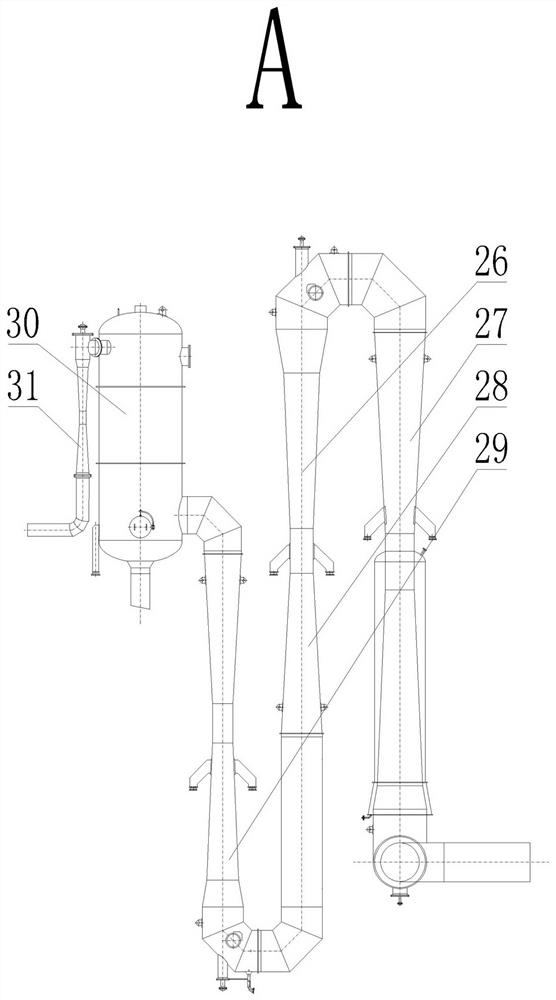

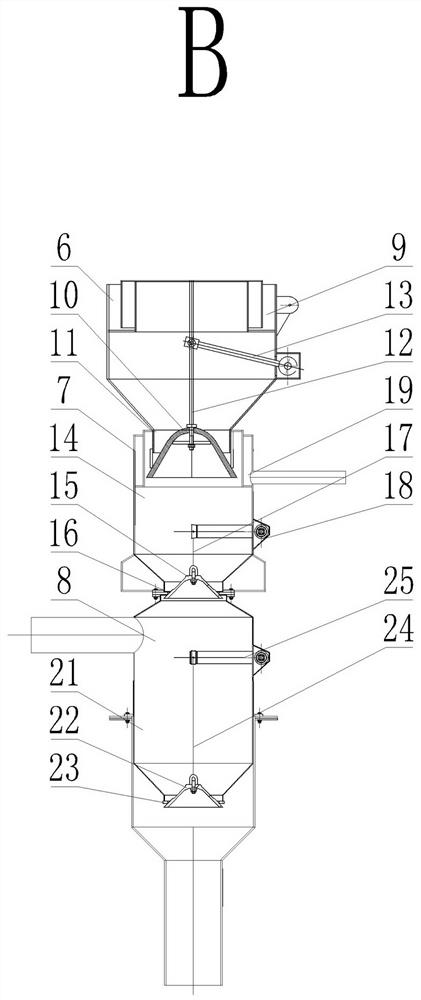

[0052] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0053] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 As shown, the process method for preparing pyrolysis oil and gas from waste tires is characterized in that: Step 1, the pyrolysis of waste tires is mainly aimed at recovering pyrolysis oil and pyrolysis carbon, and further preparing products such as fuel oil and carbon black. If the pyrolysis gas is It is undoubtedly uneconomical as the main product, because increasing the yield of pyrolysis gas requires a higher pyrolysis temperature of 550-600°C to break the chain hydrocarbons of pyrolysis oil with larger molecular weight to generate methane, ethane, Pyrolysis gas mainly composed of ethylene, propylene and other components, the higher pyrolysis temperature makes part of the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com