Operation method of waste tire pyrolysis reaction furnace

A waste tire, pyrolysis reaction technology, used in coke ovens, preparation of liquid hydrocarbon mixtures, special forms of dry distillation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

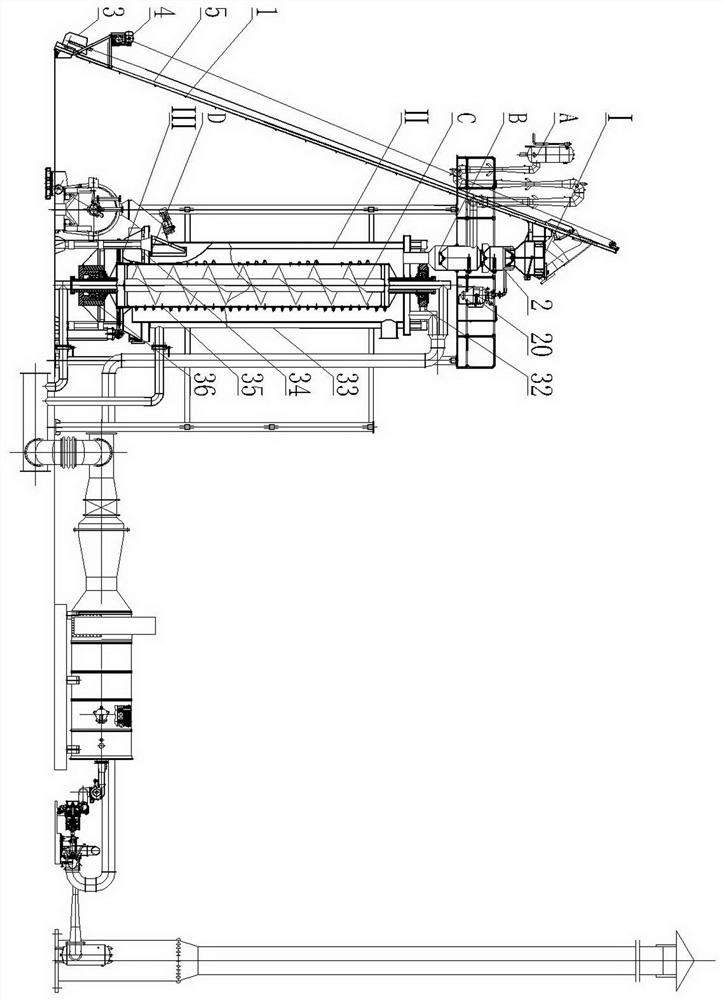

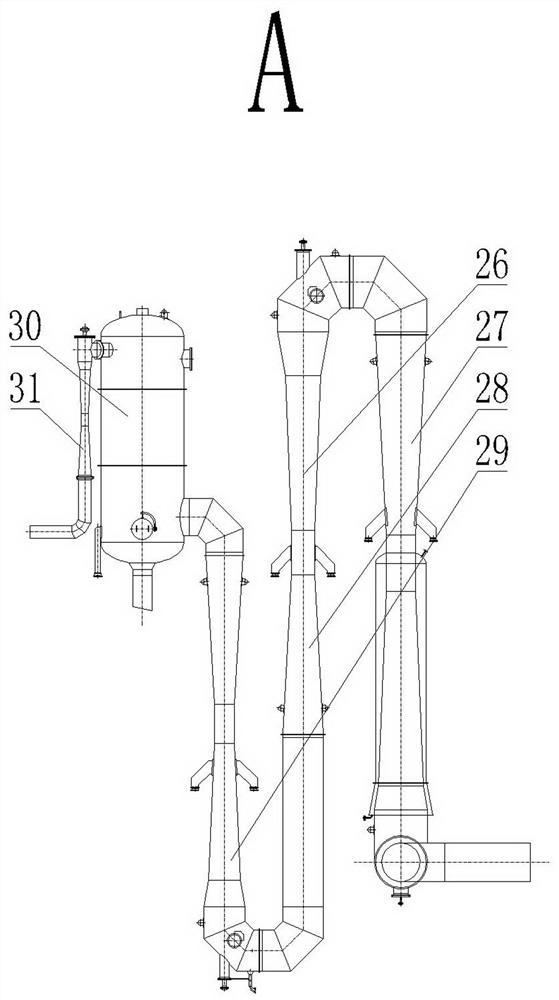

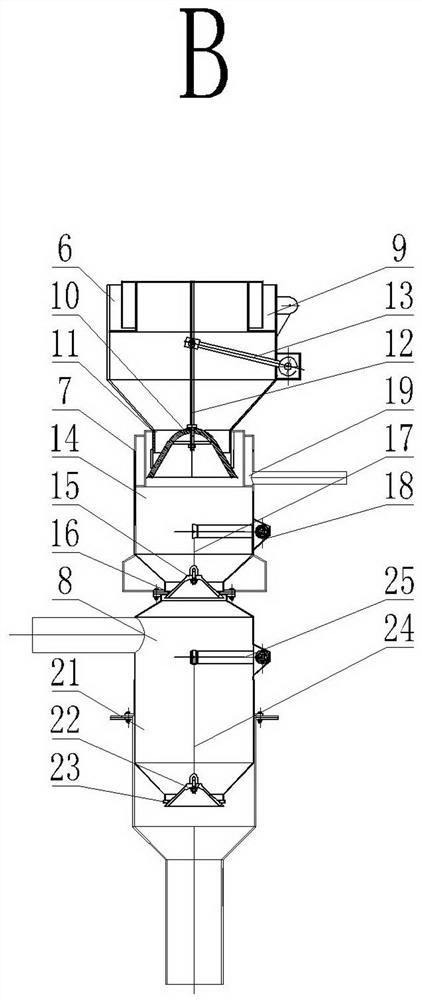

[0056] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10As shown, the operation method of the waste tire pyrolysis reaction furnace is characterized in that: Step 1, the waste tires are broken into 3-4cm-sized rubber blocks, weighed by the self-weighing trolley 3, driven by the pulley traction assembly 4 and sent along the lifting track 5 To the three-section bell feeding mechanism 2, the waste tire rubber blocks transported by the bucket trolley mechanism 1 are piled up in the bell storage bin 6 of the first section, and the accumulation amount should account for ¾ volume of the hopper body 9 of the first section. 7. The bell jar storage bins 8 at the end section are all in a sealed state, and the inert exhaust gas is output from the tail gas recovery buffer ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com