High-speed closed switch

A closed switch, high-speed technology, applied in electrical switches, power devices inside switches, electrical components, etc., can solve problems such as poor contact, low switch closing speed, arc oxidation, etc. The effect of a small risk of electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

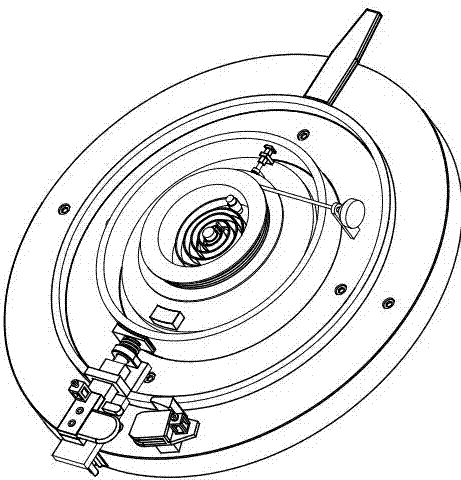

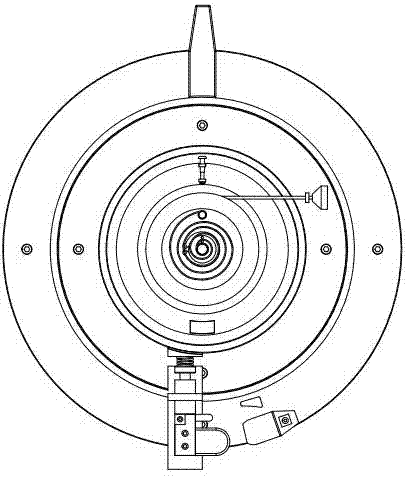

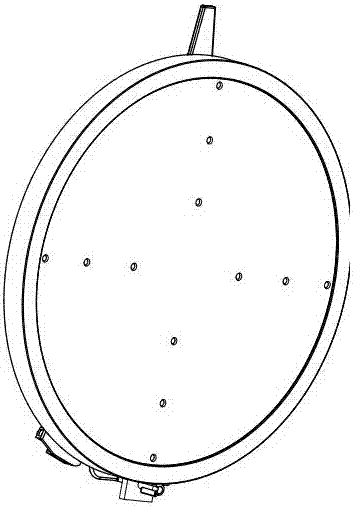

[0028] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown, a high-speed closing switch includes an end cover 1, a rotating mechanism 2, a moving contact assembly 3, a transmission ring 4, a first fixing assembly 5, a second fixing assembly 6, a third fixing assembly 7, a driving module 8, The coil spring 9 is characterized in that: the first fixing assembly 5 is fixedly installed on the end cover 1, and the slip ring 201 at the bottom of the rotating mechanism 2 is rotatably installed in the first circular groove on the rear end surface of the first circular seat 501 507, the moving contact assembly 3 is installed on the rotating mechanism 2; the second fixing assembly 6 is fixedly installed on the end cover 1, and the transmission ring 4 is installed on the rear end surface of the second ring seat 601 by rotating the flange at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com