Hall current detection device

A detection device, Hall current technology, applied in the direction of measurement device, voltage/current isolation, measurement of electrical variables, etc., can solve problems such as reducing production efficiency, nonlinearity, and electric shock danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

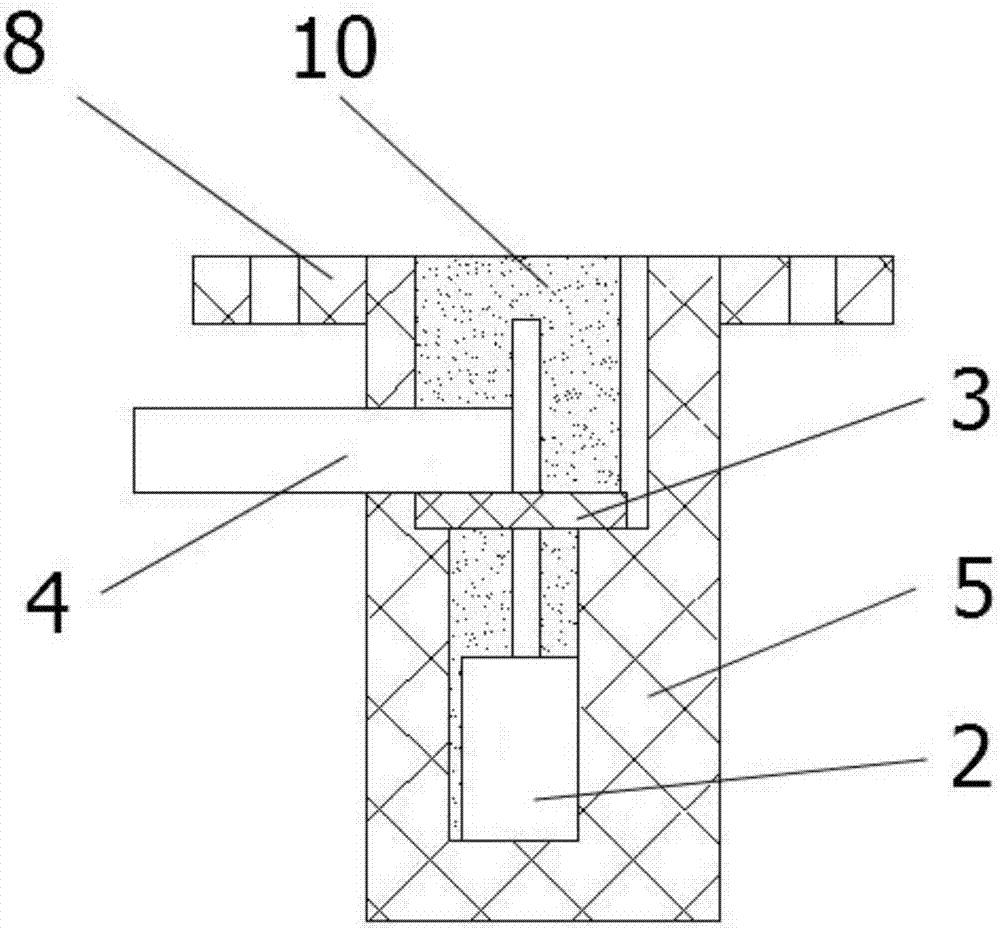

[0046] Such as figure 1 , figure 2 As shown, a Hall current detection device provided in this embodiment includes a current-carrying conductor 1 , an insulating housing structure, a detection assembly and a connecting housing 5 .

[0047] There are various specific forms of the insulating shell structure. In this embodiment, the insulating shell structure includes a first insulating shell 6 and a second insulating shell 7 . The current-carrying conductor 1 is installed on the first insulating shell 6 and is directly and fixedly connected with the first insulating shell 6 ; the second insulating shell 7 is fixedly connected with the first insulating shell 6 . As an alternative embodiment, the insulating case structure may also include only the first insulating case 6 (embodiment 3) or only the second insulating case 7 .

[0048] The detection assembly is used to detect the current passing through the current-carrying conductor 1, and includes a Hall element 2 arranged close ...

Embodiment 2

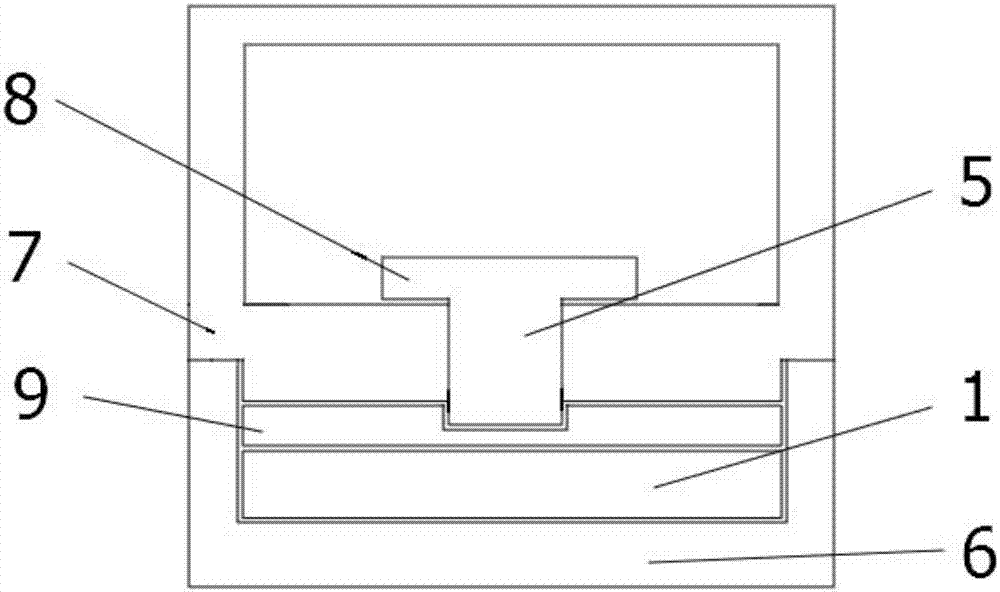

[0057] Such as figure 1 , image 3 As shown, the Hall current detection device provided in this embodiment does not include a controller on the basis of Embodiment 1, and the second insulating casing 7 is another structure indirectly fixedly connected to the current-carrying conductor 1 .

[0058] It should be noted that, in this embodiment, the first insulating shell 6, the second insulating shell 7 and the current-carrying conductor 1 are connected together to form a whole, and the connecting shell 5 is installed on On the second insulating shell 7, it is only necessary to install or disassemble between the connecting shell 5 and the second insulating shell 7, so that the detection assembly can be installed or disassembled without power failure. .

[0059] Refer to Embodiment 1 for the positional relationship between the connection housing 5 and the current-carrying conductor 1. It should be added that in this embodiment, the connection between the current-carrying conduct...

Embodiment 3

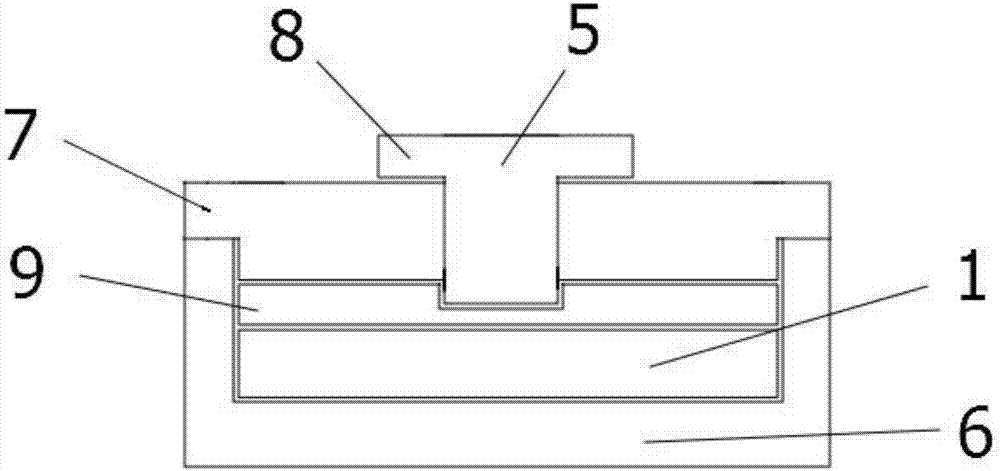

[0062] Such as figure 1 , Figure 4 As shown, the present embodiment provides a Hall current detection device. On the basis of Embodiment 1, the insulating housing structure only includes the first insulating housing 6 and does not include the second insulating housing 7. The connecting shell 5 is detachably fixedly installed with the first insulating shell 6 .

[0063] It should be noted that, in this embodiment, by directly installing the connecting shell 5 on the first insulating shell 6, it is only necessary to carry out the connection between the connecting shell 5 and the first insulating shell 6. Installing or dismounting means that the detection components can be installed or disassembled even when the power supply is not interrupted. . The place where the current-carrying conductor 1 is close to the Hall element 2 can be arranged in a convex, flat or concave shape, so that a certain distance can be achieved between the current-carrying conductor 1 and the Hall elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com