A method for dismantling a faulty low-voltage arrester with electricity

A lightning arrester and low-voltage technology, which is applied in the field of lightning arresters, can solve the problems of inconvenient single-person operation, limited space inside the installation cabinet, and the wrench is easy to touch the live parts, etc., to facilitate live work on the pole, convenient maintenance and replacement, and easy to carry around Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

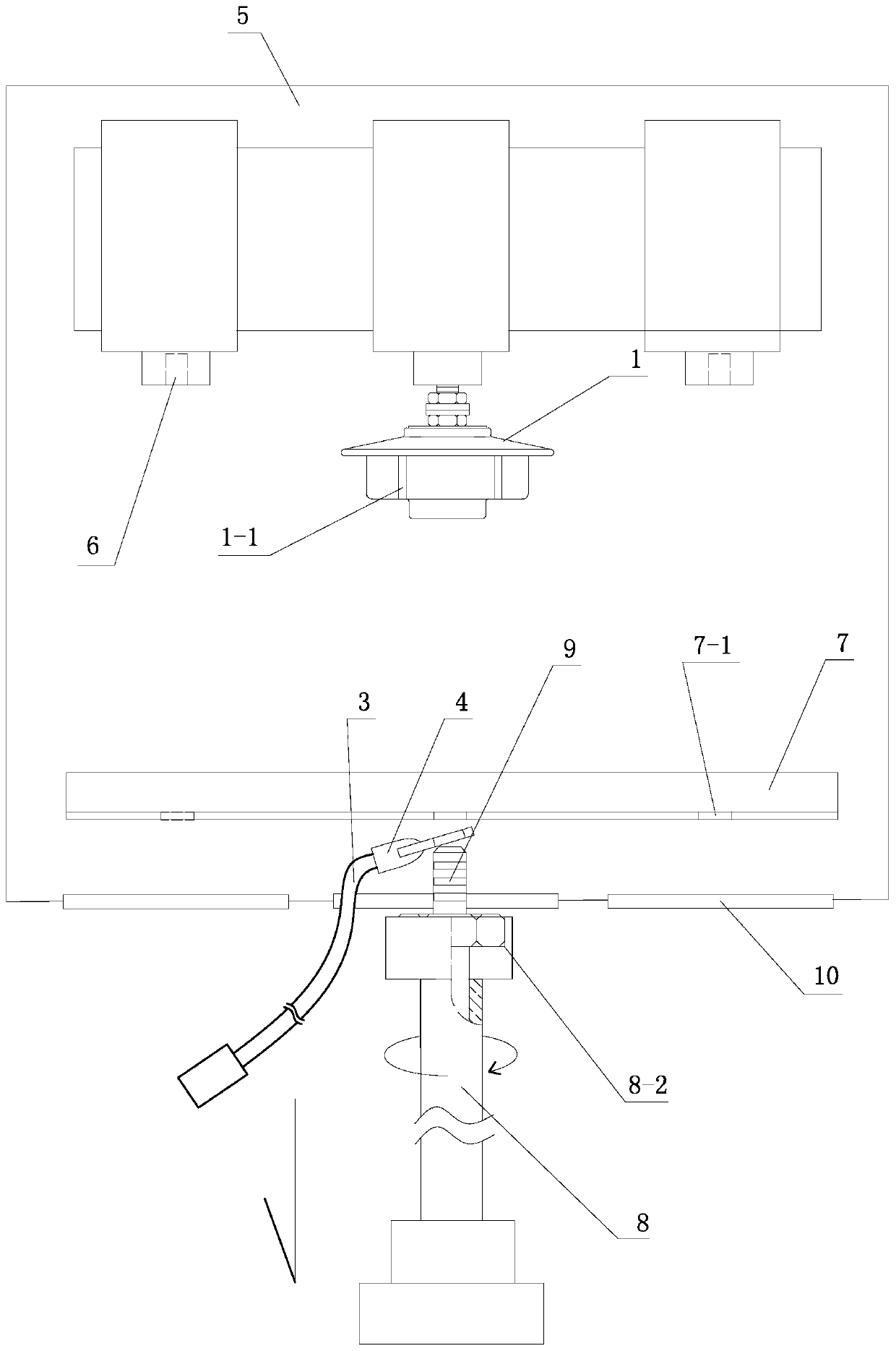

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

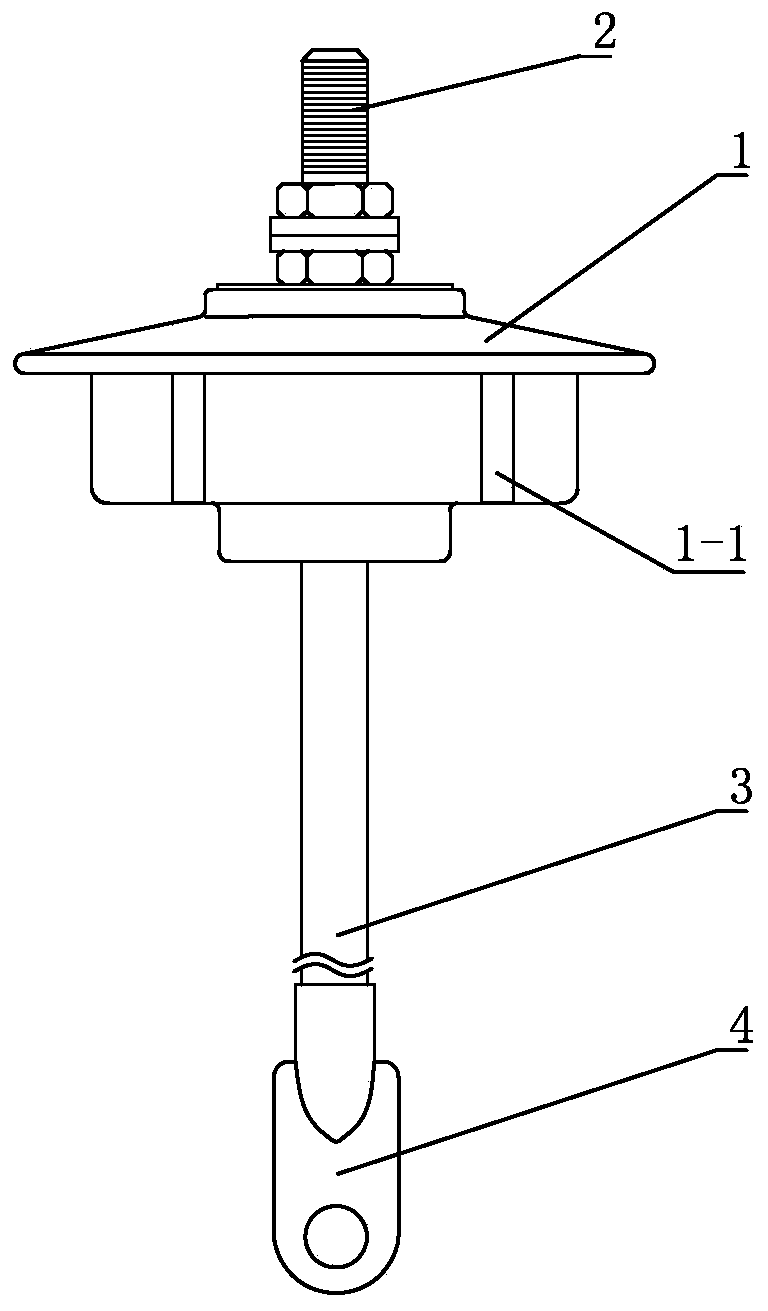

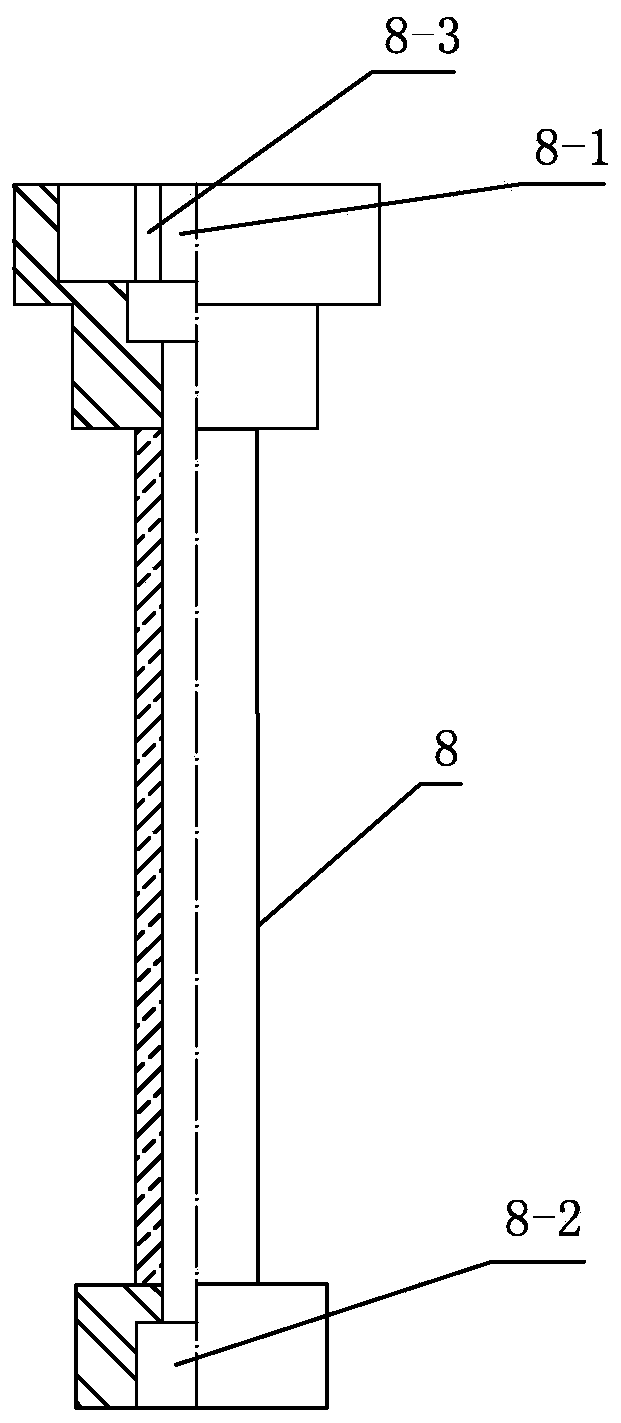

[0045] The low-voltage arrester described in the technical solution of the present invention includes an externally threaded screw terminal located at the upper end of the low-voltage arrester body, and a grounding lead located at the lower end of the low-voltage arrester body for connecting to the grounding electrode.

[0046] The low-voltage arrester is installed in the on-site cabinet on the pole; a three-phase knife switch is arranged in the on-site cabinet, and a low-voltage arrester is respectively installed at the vertical internal thread fixing holes below each phase knife switch.

[0047] The low-voltage arrester is screwed and fastened to the vertical internal thread fixing hole below each phase knife switch through the externally threaded screw terminal on the upper end of the low-voltage arrester body; the grounding lead at the lower end of each low-voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com