Superaudio heater

An ultra-audio and heater technology, applied in induction heating, ohmic resistance heating, induction heating devices, etc., can solve the problems of easy explosion, inconvenience, easy to risk electric shock, induction coil repair and maintenance, etc., and the heating speed can be adjusted. , Solve the effect of inconvenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

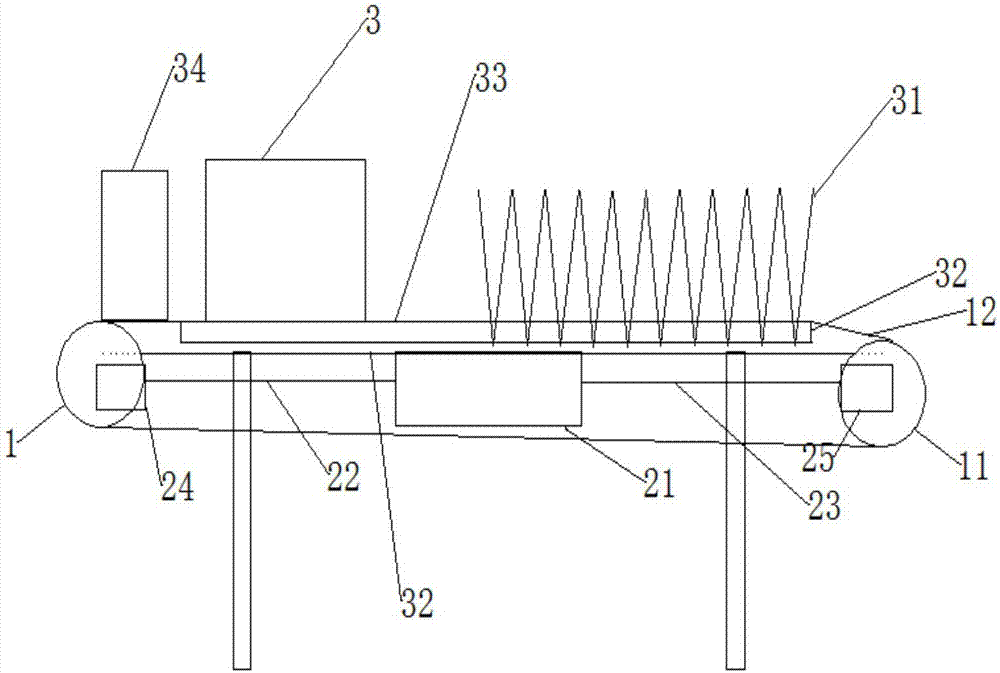

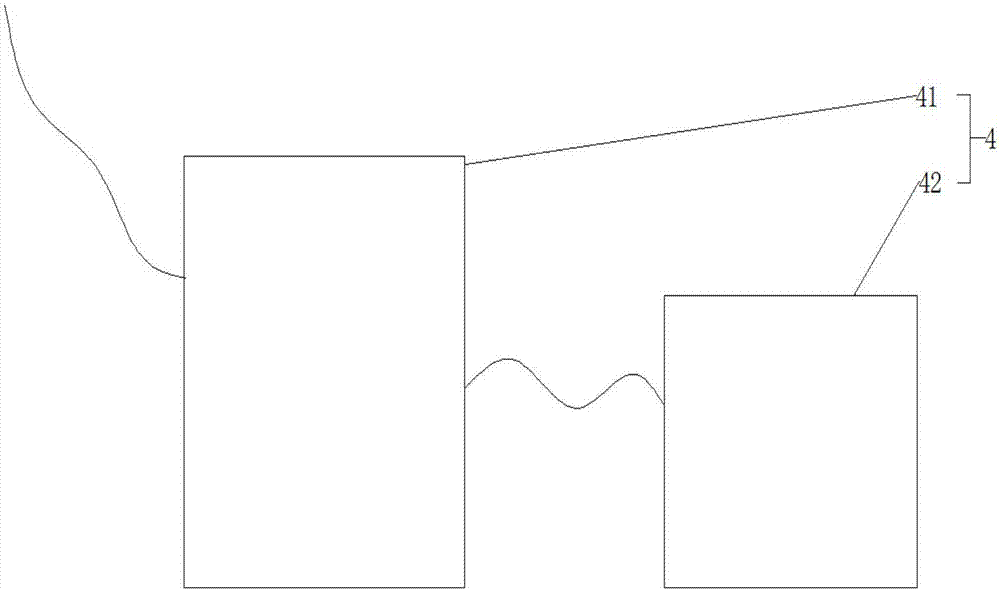

[0012] Such as figure 1 , 2 Shown, a kind of supersonic heater, it is characterized in that, described supersonic heater comprises body 4 and operating surface 32, and PLC controller 21 is fixed on being arranged below operating surface 32, and the first drive wheel 1 and the second drive The wheels 11 are respectively fixed on both sides of the operating table surface 32, the first servo motor 24 and the second servo motor 25 are respectively arranged on the axial outside of the first driving wheel 1 and the second driving wheel 11, and the PLC controller 21 passes the first data The line 22 and the second data line 23 are respectively connected with the first servo motor 1 and the second servo motor 11, the first servo motor 24 controls the operation of the first driving wheel 1, and the second servo motor 25 controls the operation of the second driving wheel 11; The heat insulation board 32 is laid horizontally on the operation table 32, and the Naki heat insulation soft f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com